Automatic anchoring net connecting device for underground coal mine

An automatic connection and automatic connection technology, which is applied in shaft equipment, shaft lining, underground chambers, etc., can solve the problems of high labor intensity, low efficiency, and difficulty in ensuring safety for workers, achieve compact structure, improve networking efficiency, and save workers. The effect of labor time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

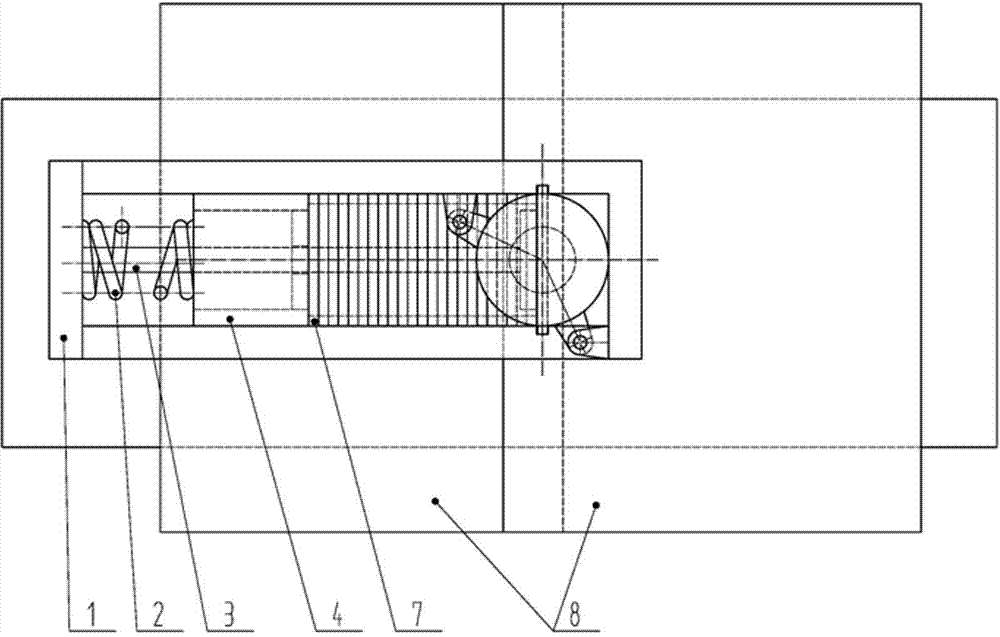

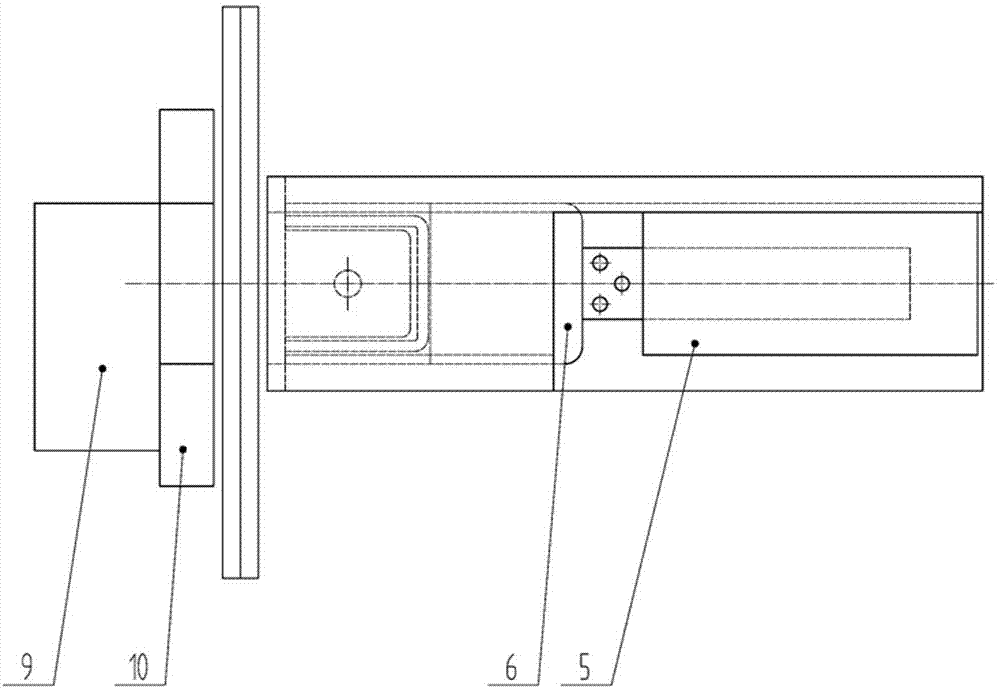

[0018] Coal mine underground automatic connection anchor network device includes nailing device 1, spring 2, guide rod 3, needle feeding block 4, needle pushing cylinder 5, pin pushing plate 6, connecting needle 7, nail winding mechanism 9, winding block 10, hydraulic pressure system and other components. The automatic connection anchor net device is installed at the front end or rear end of the temporary support bracket of the fully mechanized excavation face, and the anchor net is sent to the automatic connection anchor net device through the net feeding device to realize the automatic connection of the anchor net.

[0019] The nailing device 1 is a box-shaped structure, the cylinder body of the needle pushing cylinder 5 is fixed in the nailing device 1, the front end of the piston rod of the pushing needle cylinder 5 is connected to the needle p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com