Crankless piston type air compressor

An air compressor and piston-type technology, applied in the field of air compressors, can solve the problems of low efficiency and heavy weight, and achieve the effects of high efficiency, weight reduction and power saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

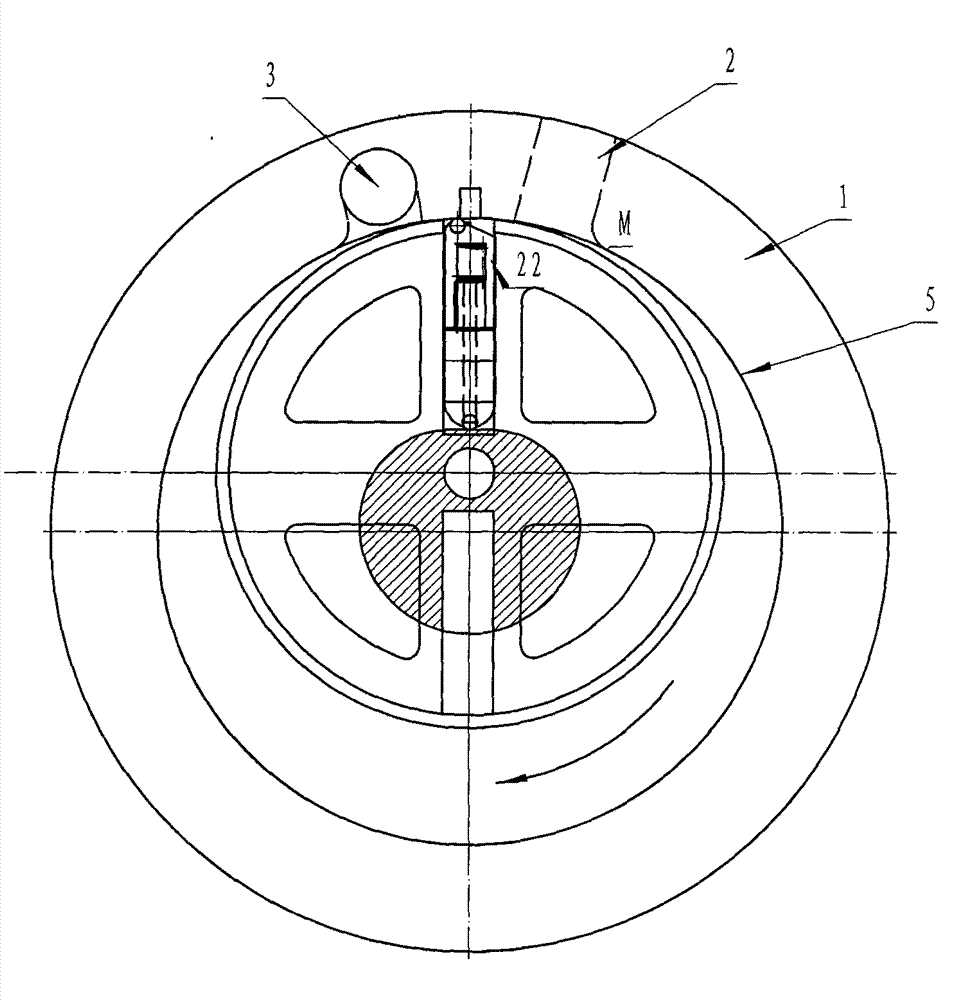

[0043] For the implementation of the body, we refer to figure 1 To illustrate; we assume that the air compressor is running normally, and the piston 22 runs clockwise in the direction shown by the arrow in the figure; at this time, the piston runs in the sealing area. The piston continues to run under the drive of the motor; when the piston passes through the sealing area, the top of the piston passes through point M in the figure and starts to suck in fresh air from the open steam inlet 2; at the same time, the piston moves forward to compress the air sucked in the previous stroke The compressed air enters the storage cylinder through the check valve in the check hole 3; at the same time, the piston runs in the same direction and sucks fresh air through the open air intake hole without any resistance. The motor drives the piston to continue running through the spokes. Until the completion of a cycle of compression work; through the sealing area, immediately start the next cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com