Method for manufacturing high-accuracy self-lubrication bearings by transfer film technology

A self-lubricating bearing and transfer film technology, applied in the field of bearing manufacturing, can solve the problems of low friction coefficient and difficulty in controlling the preparation precision of self-lubricating layer, and achieve the effect of high preparation precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

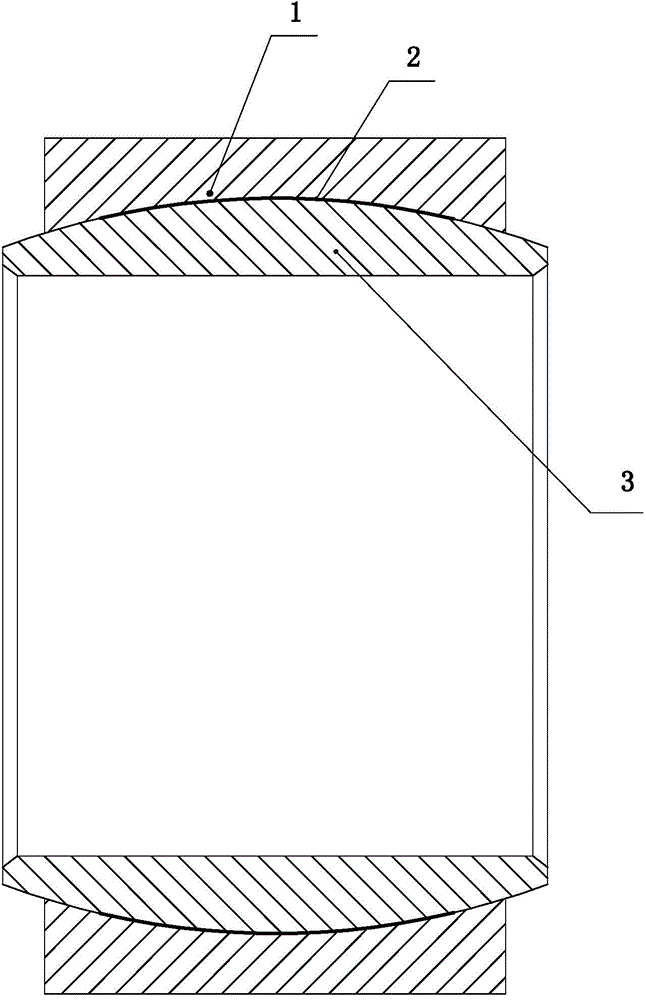

Image

Examples

Embodiment Construction

[0021] During the use of self-lubricating bearings, according to different working environments, the requirements for the self-lubricating layer of self-lubricating bearings are also different. The requirements for the self-lubricating layer include low friction coefficient, high life, strong bearing capacity and high temperature resistance. The following describes the embodiments of the present invention according to the different requirements for the self-lubricating layer.

[0022] The steps to prepare a self-lubricating bearing with a low coefficient of friction are:

[0023] (1) Prepare a self-lubricating material based on polytetrafluoroethylene. The main component of the self-lubricating material is polytetrafluoroethylene, and it also contains bronze powder and carbon fiber. The proportions of the above three components are: polytetrafluoroethylene 70%-80%, bronze powder 10%-15%, Carbon fiber 10%-15%. When preparing the self-lubricating material, a certain ratio of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com