Steel wire reinforced composite water supply pipe

A technology for enhancing composite and water supply pipes, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipes, etc., can solve the problems of processing equipment and processing difficulties, affecting the normal flow of liquids, and high manufacturing costs, achieving low processing difficulty, The effect of small footprint and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

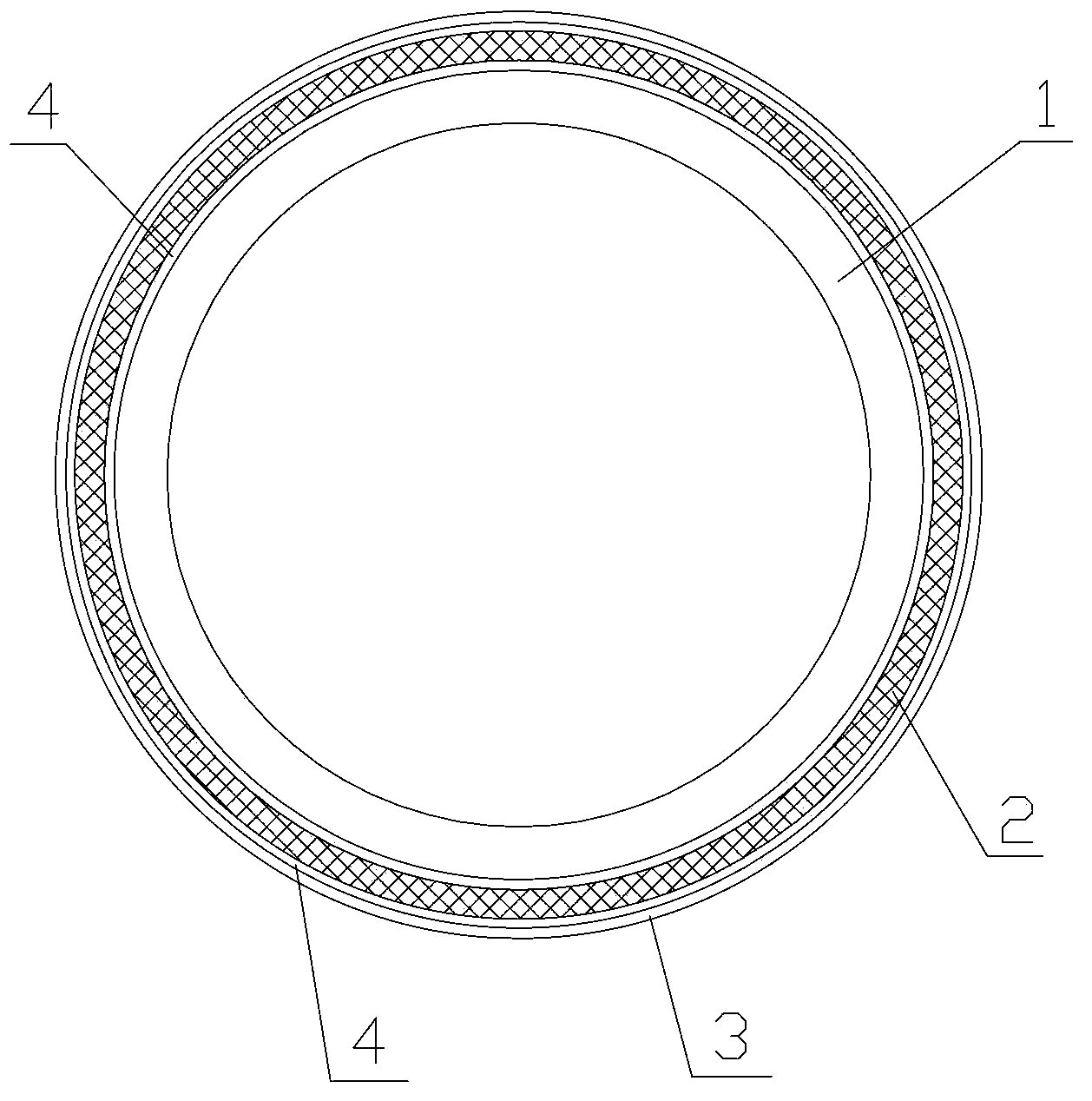

[0013] Such as figure 1 As shown, the steel wire reinforced composite water supply pipe includes an inner layer 1, a reinforced layer 2 and a protective layer 3. The inner layer 1 is made of polyethylene material, and the reinforced layer 2 is composed of a steel wire mesh layer and a hot melt adhesive layer 4 to protect The layer 3 is made of polyethylene material, and a hot melt adhesive layer 4 is provided between the steel mesh layer, the inner layer 1 and the protective layer 3 respectively.

[0014] In this embodiment, the steel mesh layer is composed of one layer, two layers or three layers of steel mesh, and a hot melt adhesive layer 4 is arranged between each layer of steel mesh, and the mesh size of the steel mesh layer from outside to inside is Decrease layer by layer, the hot melt adhesive is polyethylene hot melt adhesive, the steel wire constituting the steel mesh is spring steel wire, the diameter of the spring steel wire is 1.0 to 5 mm, and the surface of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap