Nitrogen displacement system for LNG (Liquefied Natural Gas) storage tank

A nitrogen replacement and storage tank technology, which is applied to fixed-capacity gas storage tanks, container discharge methods, and equipment loaded into pressure vessels. and other problems, to achieve the effect of speeding up the nitrogen replacement time and shortening the drying and inerting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

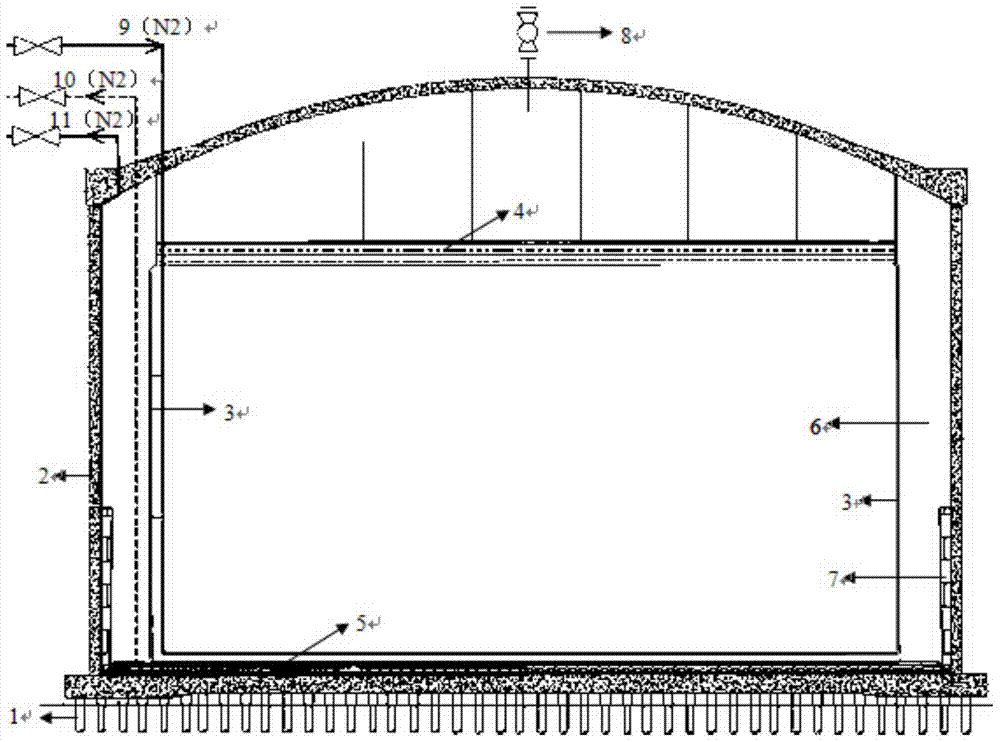

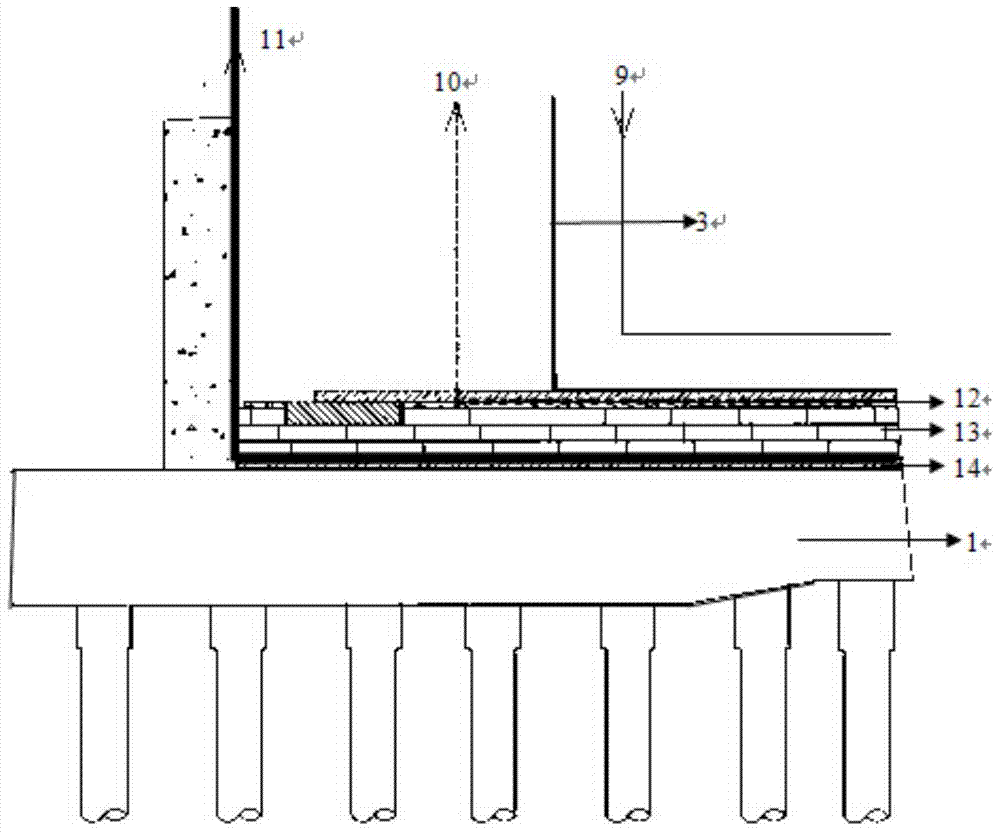

[0035] Such as figure 1 Shown is a structural schematic diagram of the cooperation of the nitrogen replacement system and the LNG storage tank provided by the present invention. The main structure of the LNG storage tank is composed of the following seven parts: pile cap foundation 1; prestressed concrete outer tank 2; inner tank 3; aluminum ceiling structure (including ceiling insulation layer) 4; tank bottom insulation layer 5; tank wall insulation layer 6; thermal corner protection system (TCP) 7. Wherein, the tank bottom insulation layer 5 includes an upper concrete leveling layer 12 , a foam glass brick pressure insulation layer 13 and a lower concrete leveling layer 14 . The nitrogen replacement system of the present invention includes a nitrogen gas inlet pipe 9, a tank top manual vent valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com