Illumination system for optical detection, detection system and method using the same

A lighting system and optical inspection technology, applied in the field of optical inspection, can solve problems such as back reflection and wire defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to fully understand the purpose, features and effects of the present invention, the following specific embodiments are now used in conjunction with the accompanying drawings to give a detailed description of the present invention. The description is as follows:

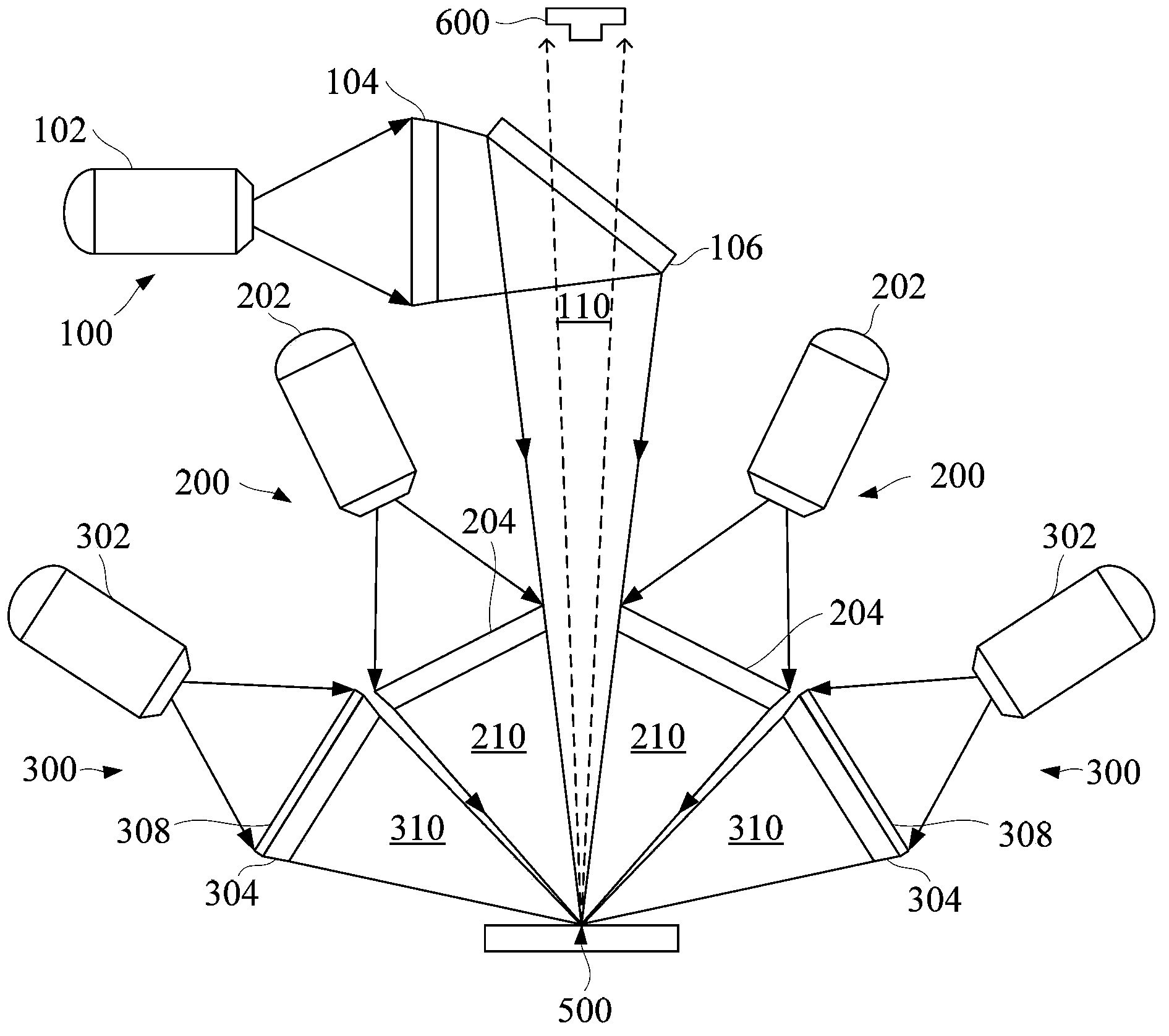

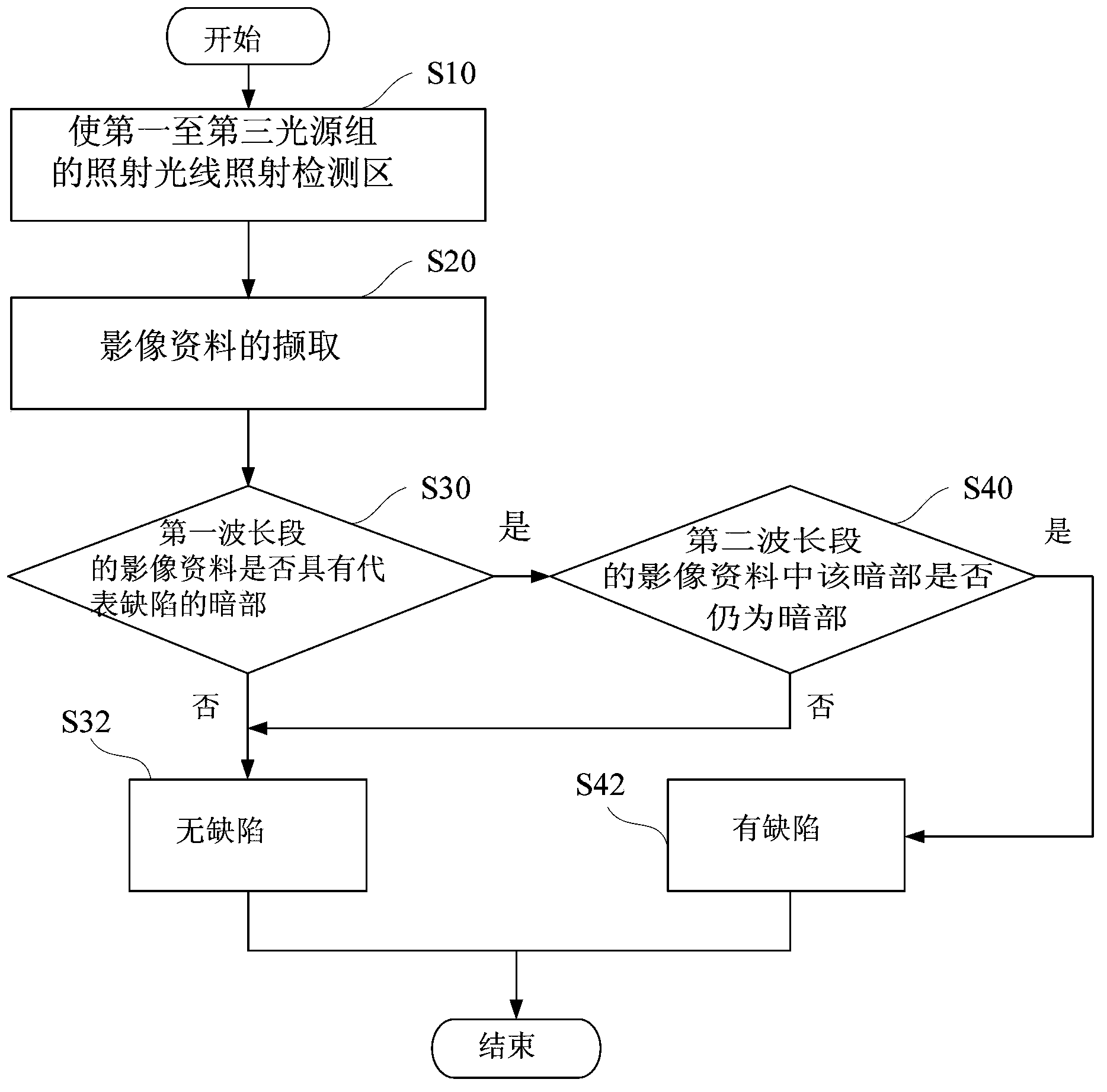

[0054] The present invention uses three sets of light source sets arranged at different illumination angles to illuminate an object to be measured (such as a circuit substrate) and the use of reflected light through different wavelength bands to detect defects and enhance optical The identification of oxidized areas and dust in the image reduces the probability of misjudgment by the imaging system.

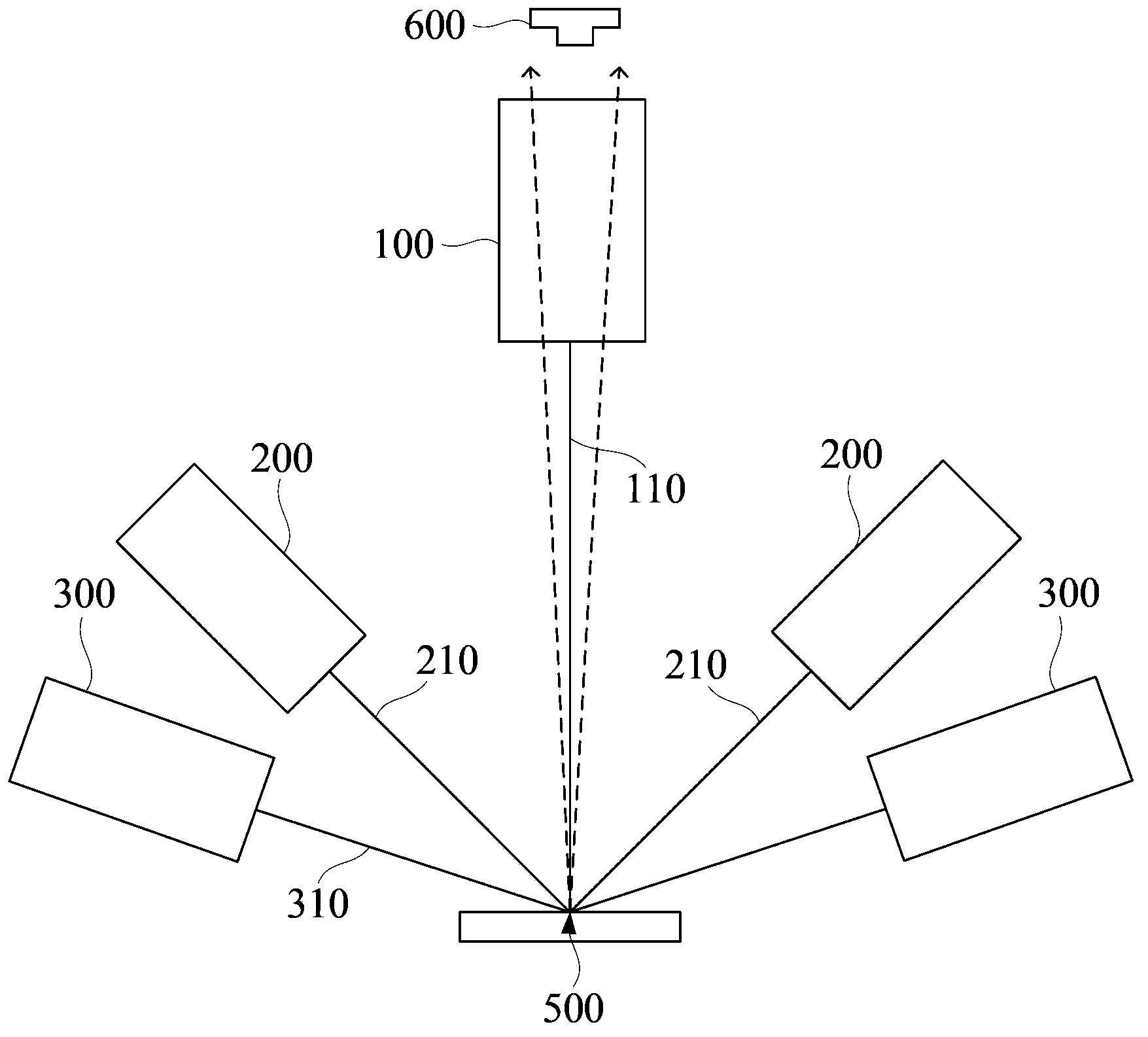

[0055] See first figure 1 , Is a system schematic diagram of the detection system in an embodiment of the present invention. The illumination system for optical detection in this embodiment of the present invention is used to provide illumination light to a detection area 500. The illumination system includes a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle of incidence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com