Automatic measurement method of wharf materials

An automatic measurement and material technology, applied in the direction of continuous material flow weighing equipment, weighing, measuring devices, etc., can solve the problems of measurement result differences, falsification, and large human resources, so as to solve the measurement accuracy and reduce work Strength and the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings.

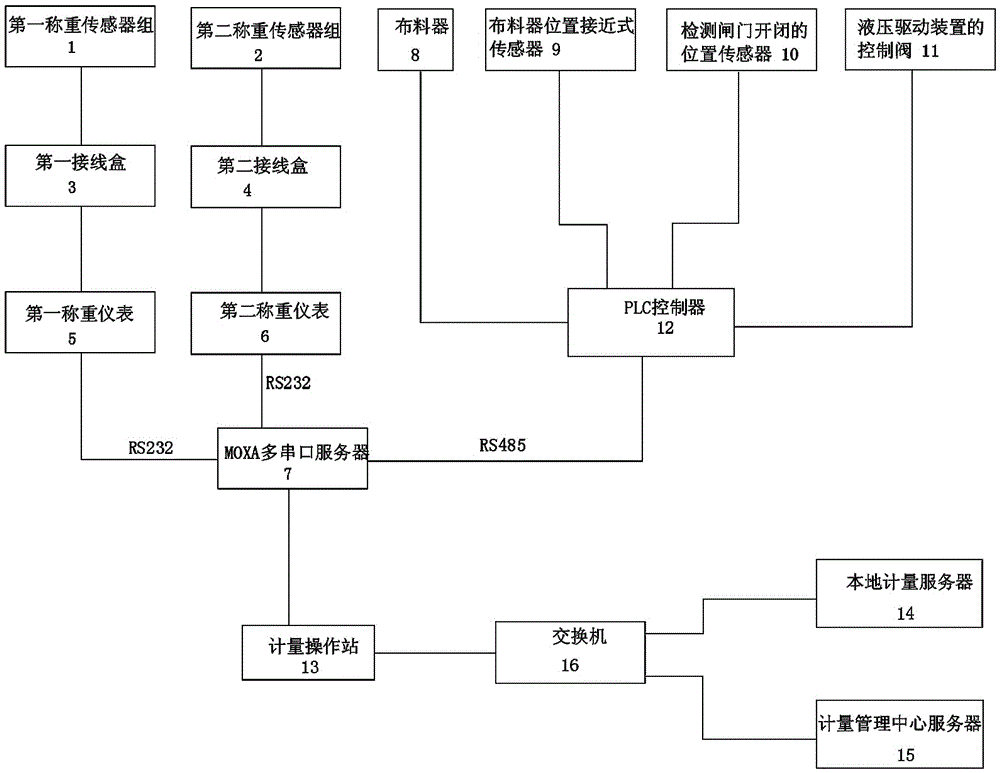

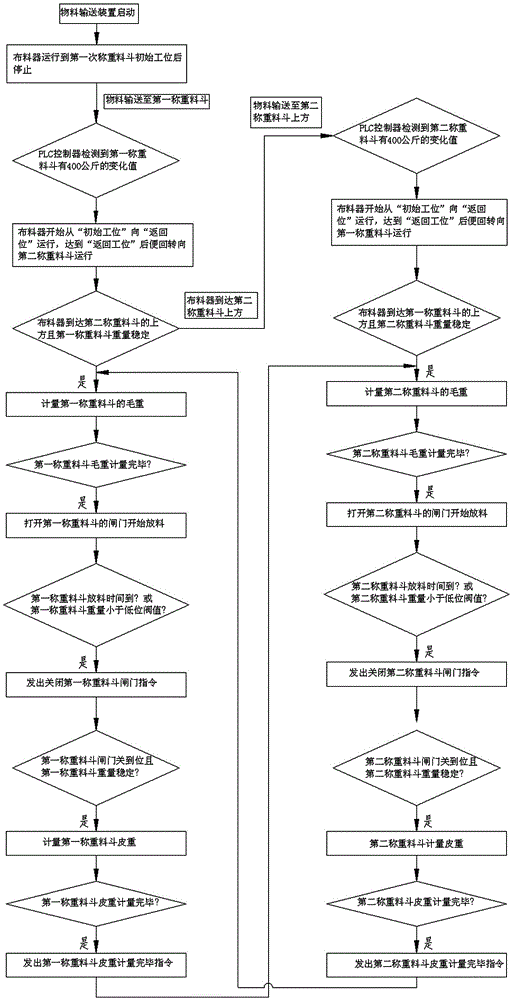

[0042] see Figure 1 to Figure 5 The shown automatic weighing method for dock materials is based on a material weighing system that includes first and second weighing devices, first and second weighing instruments 5 and 6, and a metering operation station 13 connected through a network. weighing measurement,

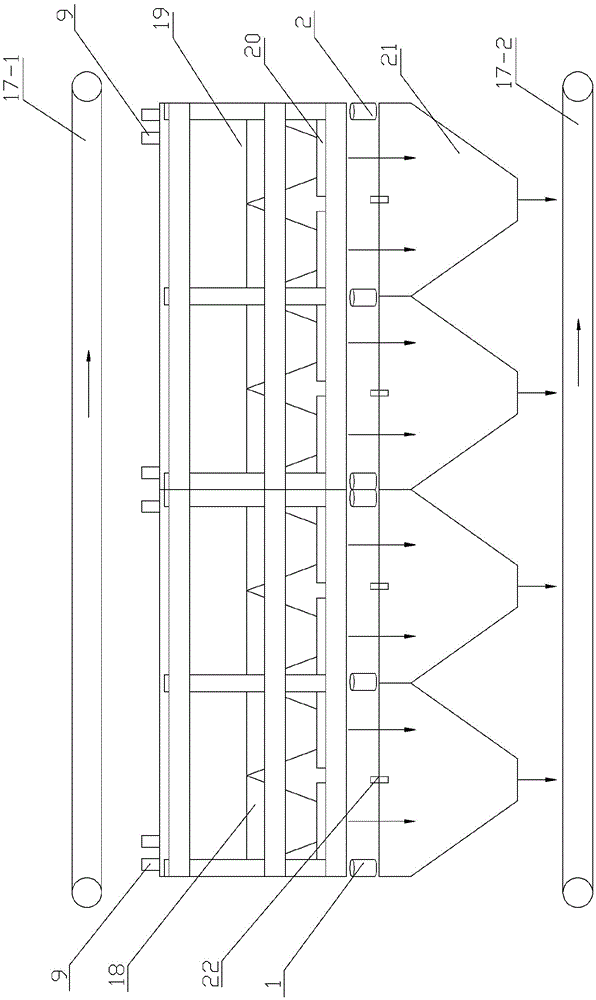

[0043] The material weighing system includes a material distributor 8 of a material conveying device, first and second weighing devices, first and second weighing instruments 5 and 6, communication cables, MOXA multi-serial port server 7, and a metering operation station 13 , the PLC controller 12 and the local metering server 14, the material conveying device adopts a belt conveying device, and the belt conveying device is divided into two sections, the first section of the belt conveying device 17-1 is connected to the distributor 8 for distributing, the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com