Ultrasonic wave phased array testing method for internal defect at bent axle R

A technology for internal defects and detection methods, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, can solve the problems of difficult adjustment, narrow probe adaptation range, etc., to achieve comprehensive detection results, improve detection reliability, and strong practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

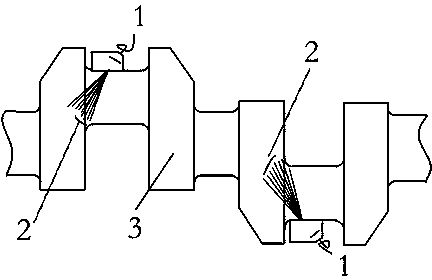

[0027] Example: such as figure 1 As shown, the ultrasonic phased array detection method for internal defects at the crankshaft R includes the following steps:

[0028] (1) Clean the journal surface of the crankshaft 3, and maintain the surface roughness at Ra≤6.3μm;

[0029] (2) Select the probe and wedge. In production practice, select the corresponding wedge according to the crankshaft of different specifications to ensure the coupling between the probe and the crankshaft journal. Since the detection surface is a curved surface, in order to ensure good coupling, the chip area should be selected For smaller probes, it is advisable to choose a one-dimensional line array probe with 8 or 16 elements, and choose a suitable wedge;

[0030] (3) Debug the probe, the debugging process includes sound velocity and zero point, delay, sensitivity calibration, ACG calibration (angle gain compensation), TCG calibration (time gain calibration);

[0031] (4) Select the scanning angle accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com