A two-stage system process control method for a hot strip mill

A process control and hot-rolled plate technology, applied in the direction of electrical program control, digital control, etc., can solve problems such as difficulty in modifying source code, inadaptability to development trends, and inconvenient interfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

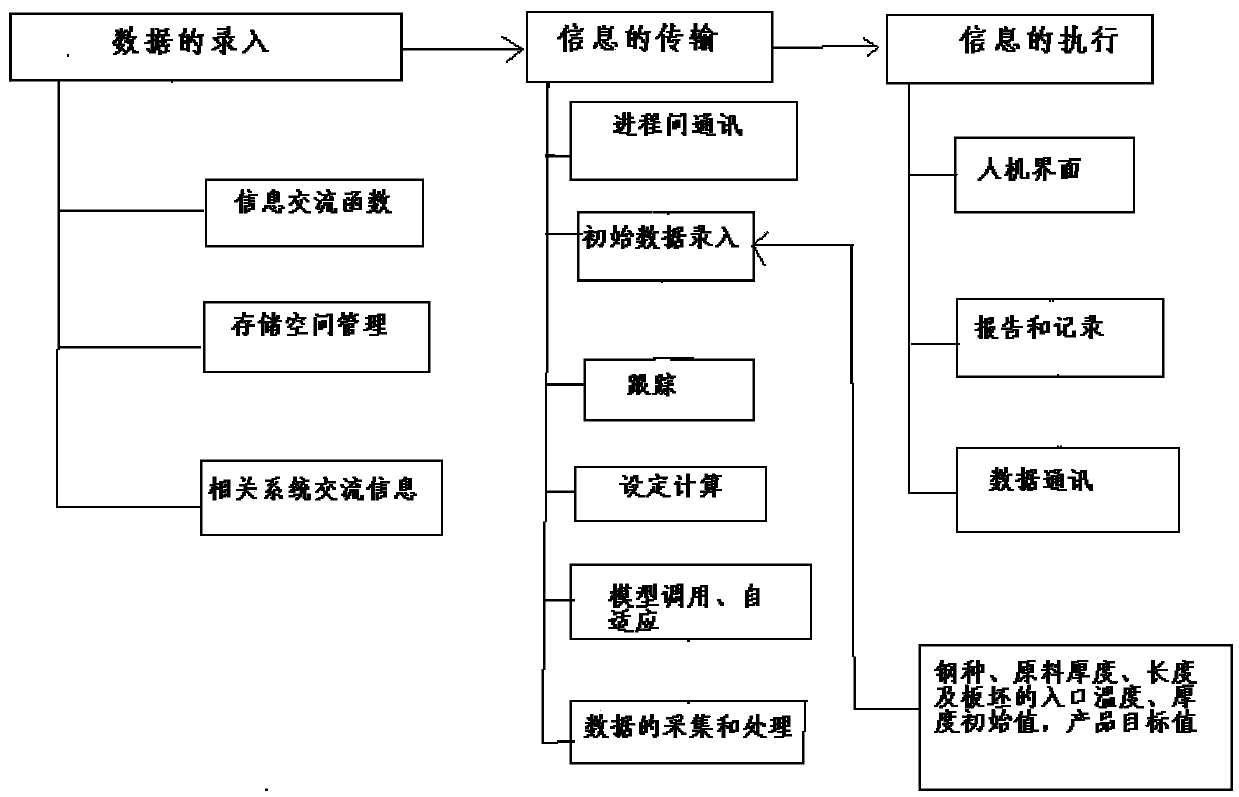

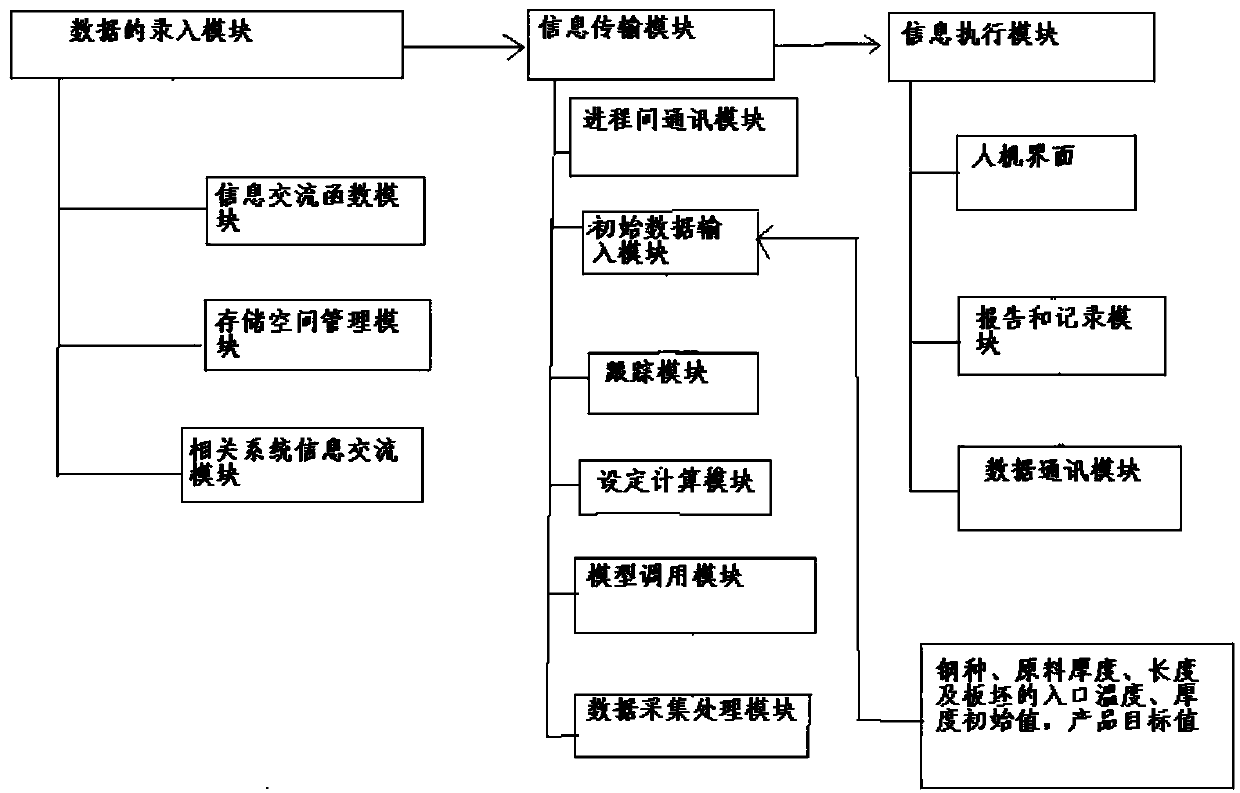

[0031] A secondary system process control method and device for a hot-rolled strip mill provided in this embodiment, such as Figures 1 to 3 Shown:

[0032] Including data entry, information transmission and information execution, the information execution includes, human-machine interface, reporting and recording, and data communication; the information transmission includes inter-process communication, initial data input, model invocation, and data collection and processing ; the steps it contains are:

[0033] 1) Inter-process communication. The inter-process communication includes a network remote object calling framework, which conceptually adopts the Microsoft .net remote object concept, and uses native C++, .netC++ and C# for codes.

[0034] 2) Input of initial data, including steel grade and slab inlet temperature, initial value of thickness, input product target value;

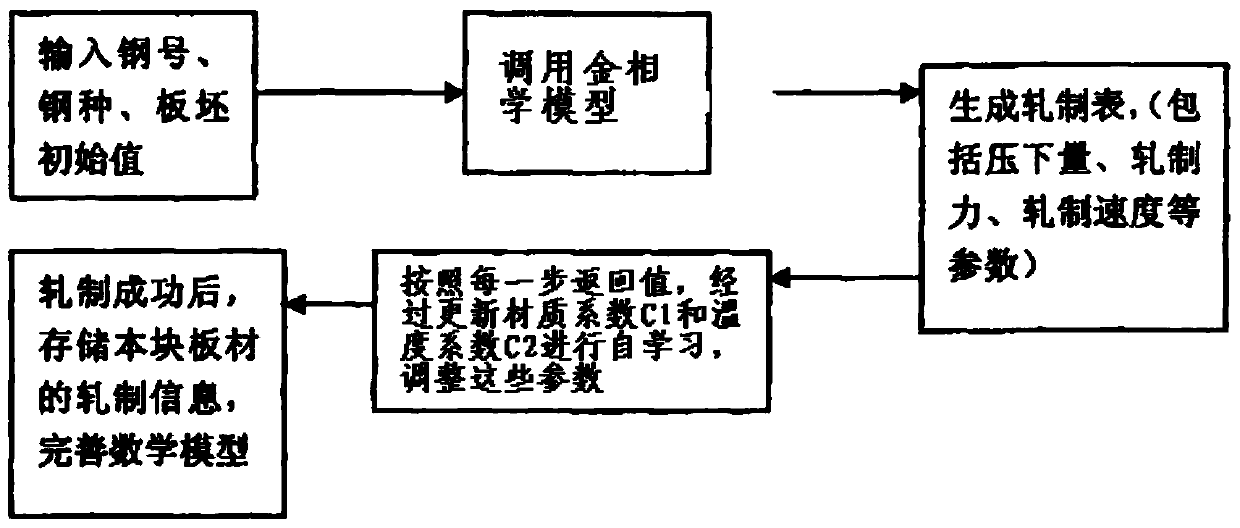

[0035] 3) Call the model, adopt the metallographic model, and use the bivariate self-study coeff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com