Metal layer formation process

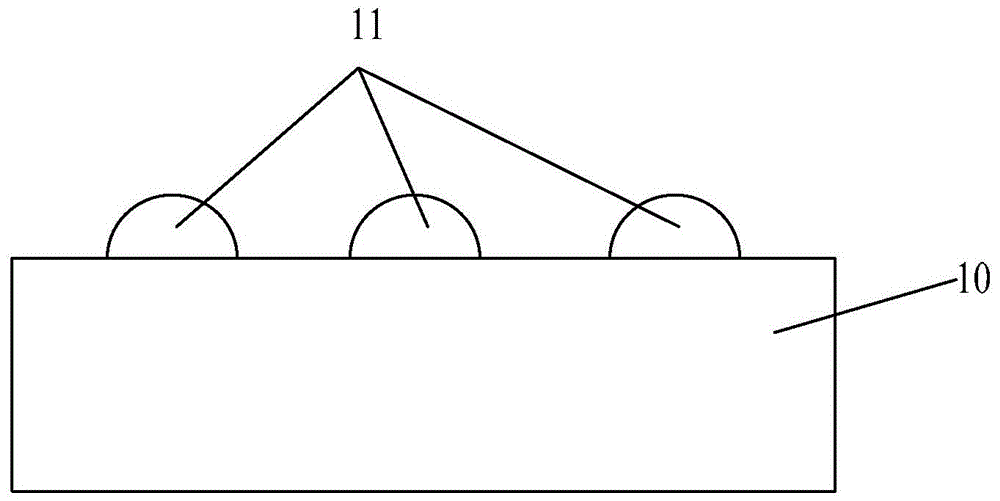

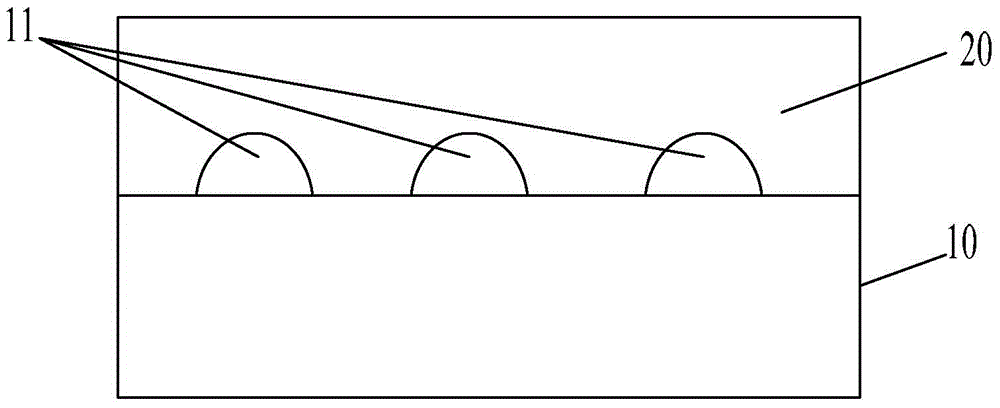

A metal layer and process technology, applied in the field of metal layer formation technology, can solve problems such as large protrusions of the metal layer, and achieve the effects of reducing contact resistance, uniform grain distribution, and good ohmic contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

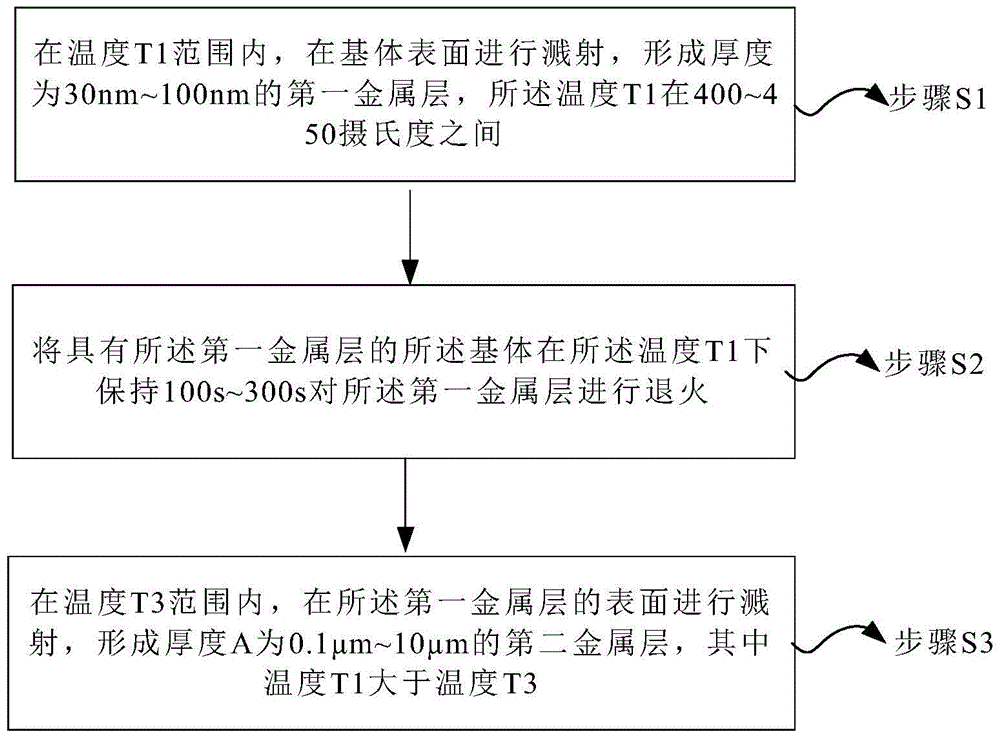

Method used

Image

Examples

Embodiment 1

[0049] First, the silicon substrate 30 is transferred from the material box to the vacuum sampling chamber, and after the vacuum chamber is pumped to a high vacuum, the silicon substrate 30 is transferred to the preheating chamber, and the preheating chamber heats the silicon substrate 30 to 450°C, and the time is controlled at Within 300 seconds. The preheating of the silicon substrate 30 makes the temperature of the silicon substrate 30 the same or close to the temperature of the first sputtering, avoiding the sudden temperature rise of the silicon substrate 30 during sputtering to cause its fracture or other physical changes on the surface, ensuring Subsequent sputtering can be performed well.

[0050] The heating temperature of the first sputtering chamber was set at 450° C. to maintain the heating temperature of the silicon substrate 30 . After the silicon substrate 30 is transferred from the preheating chamber to the first sputtering chamber, the sputtering is delayed f...

Embodiment 2

[0059] First, the silicon substrate 30 is transferred from the material box to the vacuum sampling chamber, and after the vacuum chamber is pumped to a high vacuum, the silicon substrate 30 is transferred to the preheating chamber, and the preheating chamber heats the silicon substrate 30 to 450°C, and the time is controlled at Within 300 seconds. The preheating of the silicon substrate 30 makes the temperature of the silicon substrate 30 the same or close to the temperature of the first sputtering, avoiding the sudden temperature rise of the silicon substrate 30 during sputtering to cause its fracture or other physical changes on the surface, ensuring Subsequent sputtering can be performed well.

[0060] The heating temperature of the first sputtering chamber was set at 450° C. to maintain the heating temperature of the silicon substrate 30 . After the silicon substrate 30 is transferred from the preheating chamber to the first sputtering chamber, the sputtering is delayed f...

Embodiment 3

[0063] First, the silicon substrate 30 is transferred from the material box to the vacuum sampling chamber, and after the vacuum chamber is pumped to a high vacuum, the silicon substrate 30 is transferred to the preheating chamber, and the preheating chamber heats the silicon substrate 30 to 450°C, and the time is controlled at Within 300 seconds. The preheating of the silicon substrate 30 makes the temperature of the silicon substrate 30 the same or close to the temperature of the first sputtering, avoiding the sudden temperature rise of the silicon substrate 30 during sputtering to cause its fracture or other physical changes on the surface, ensuring Subsequent sputtering can be performed well.

[0064] The heating temperature of the first sputtering chamber was set at 450° C. to maintain the heating temperature of the silicon substrate 30 . After the silicon substrate 30 is transferred from the preheating chamber to the first sputtering chamber, the sputtering is delayed f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com