Manufacturing method for a shield conductor

A technology for shielding conductors and manufacturing methods, applied in cable/conductor manufacturing, conductors, manufacturing tools, etc., can solve the problems of uniformity of metal braid and shielding tube, increase the number of parts, etc., and achieve high electrical contact reliability and parts. The effect of reducing the number of pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

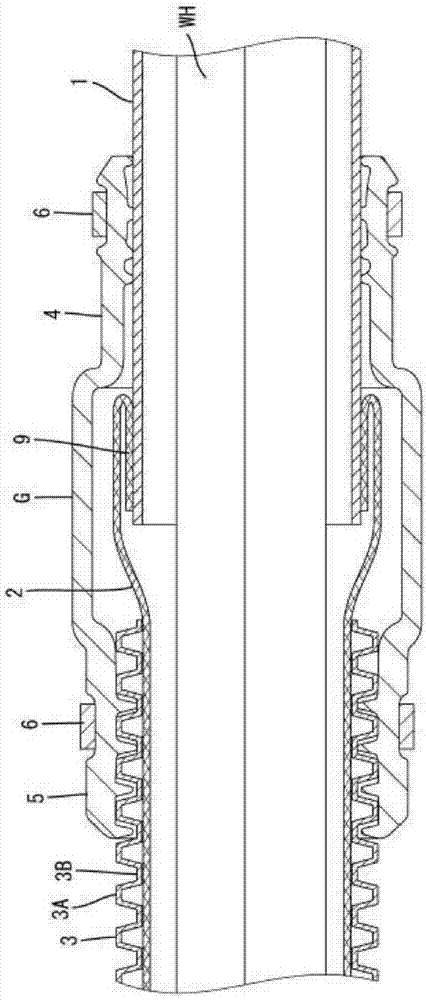

[0027] figure 1 Shown is a wiring harness WH that connects between a battery mounted in the rear compartment and an inverter mounted in the engine room in a hybrid vehicle.

[0028] The wire harness WH is composed of a plurality of electric wires. The wiring of the wire harness WH is partially inserted into the conductive metal shield tube 1 (corresponding to the connection object of the present invention). The shield pipe 1 is made of aluminum or an aluminum alloy, and is placed under the chassis of the vehicle body.

[0029] The end portion of the shielding pipe 1 is connected to the metal braided portion 2 after being introduced into the engine room from under the chassis. The metal braid 2 together with the shielding tube 1 constitutes the shielding conductor of the present invention, and is provided within a predetermined length range until it is connected to the inverter.

[0030] The metal braid 2 is formed, for example, by braiding copper-based metal wires with tin-...

Embodiment 2

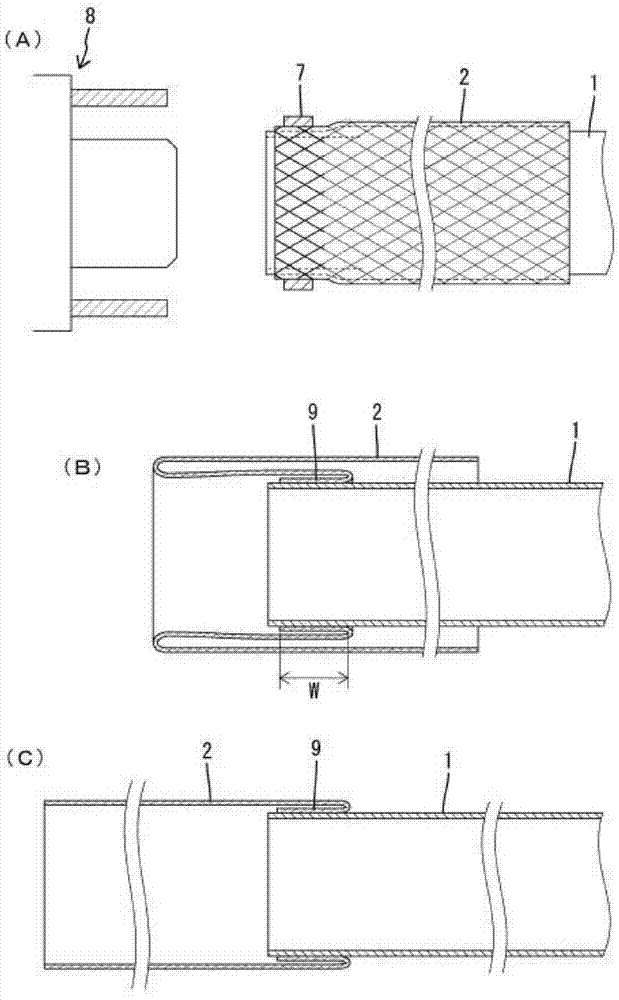

[0043] image 3 (A) (B) shows the manufacturing method of Example 2 of this invention. In Example 2, an annular groove 10 for positioning is recessed on the outer peripheral surface of the end portion of the shielding tube 20 . The annular groove 10 is formed on the entire circumference of the shield tube 20 and is wider than the width of the solder ribbon 7 . In addition, although not shown in detail, the ribbon 7 is cut into a partition groove in the axial direction, and elastically expands / returns with the partition groove as a boundary.

[0044] During ultrasonic welding, after the metal braided portion 2 is covered on the shielding tube 20, the welding ribbon 7 is embedded in the metal braided portion 2 (refer to image 3 (A)). Next, when the welding ribbon 7 is positioned in the annular groove 10 , the welding ribbon 7 can be slightly reduced in diameter by virtue of its own elastic force to exert a fastening force on the metal braided portion 2 . Therefore, the posi...

Embodiment 3

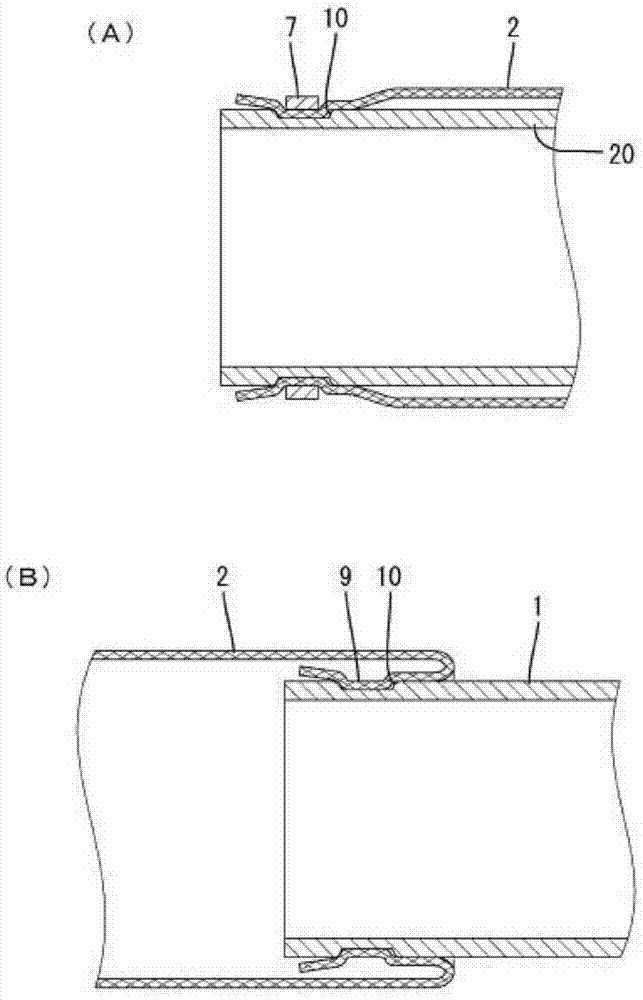

[0048] Figure 4 (A) (B) shows the manufacturing method of Example 3 of this invention. In this embodiment, a pair of flanges 31, 31 are formed on the shield tube 30, and the solder ribbon 7 is positioned between them.

[0049] That is, two flanges 31 , 31 are formed on the entire circumference of the end portion of the shielding tube 30 so as to be spaced apart from each other by a predetermined interval in the longitudinal direction. The two flanges 31 are formed such that the inner peripheral surface side of the shielding tube 30 is recessed and the outer peripheral surface side protrudes. As a result, an annular groove 32 for positioning is formed in a region sandwiched between the two flanges 31 on the outer periphery of the shielding tube 30 .

[0050] In Example 3 thus constituted, the metal braid 2 and the shielding tube 30 can be welded in the same procedure as in Example 2. FIG. In this case, the welding site 9 is also formed in the annular groove 32 along with it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com