Single-wire-type steel wire saw line

A wire saw and monofilament technology, applied in the direction of fine working devices, stone processing tools, manufacturing tools, etc., to achieve the effect of improving cutting efficiency and increasing cutting kinetic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

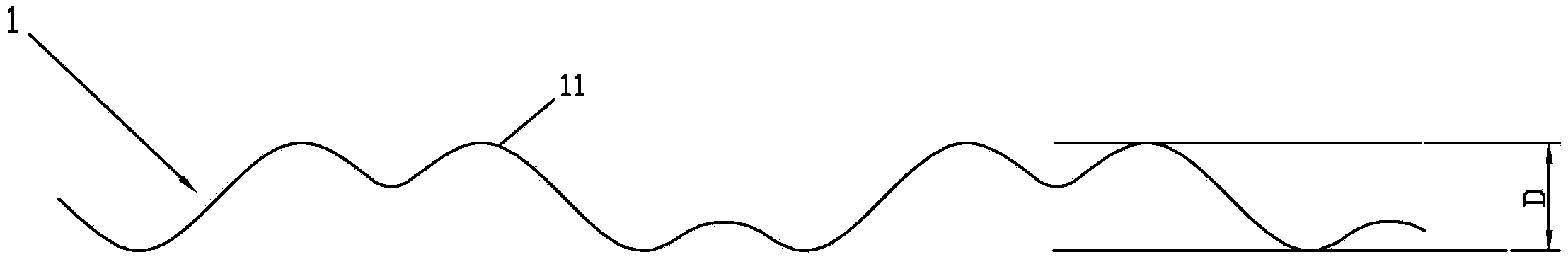

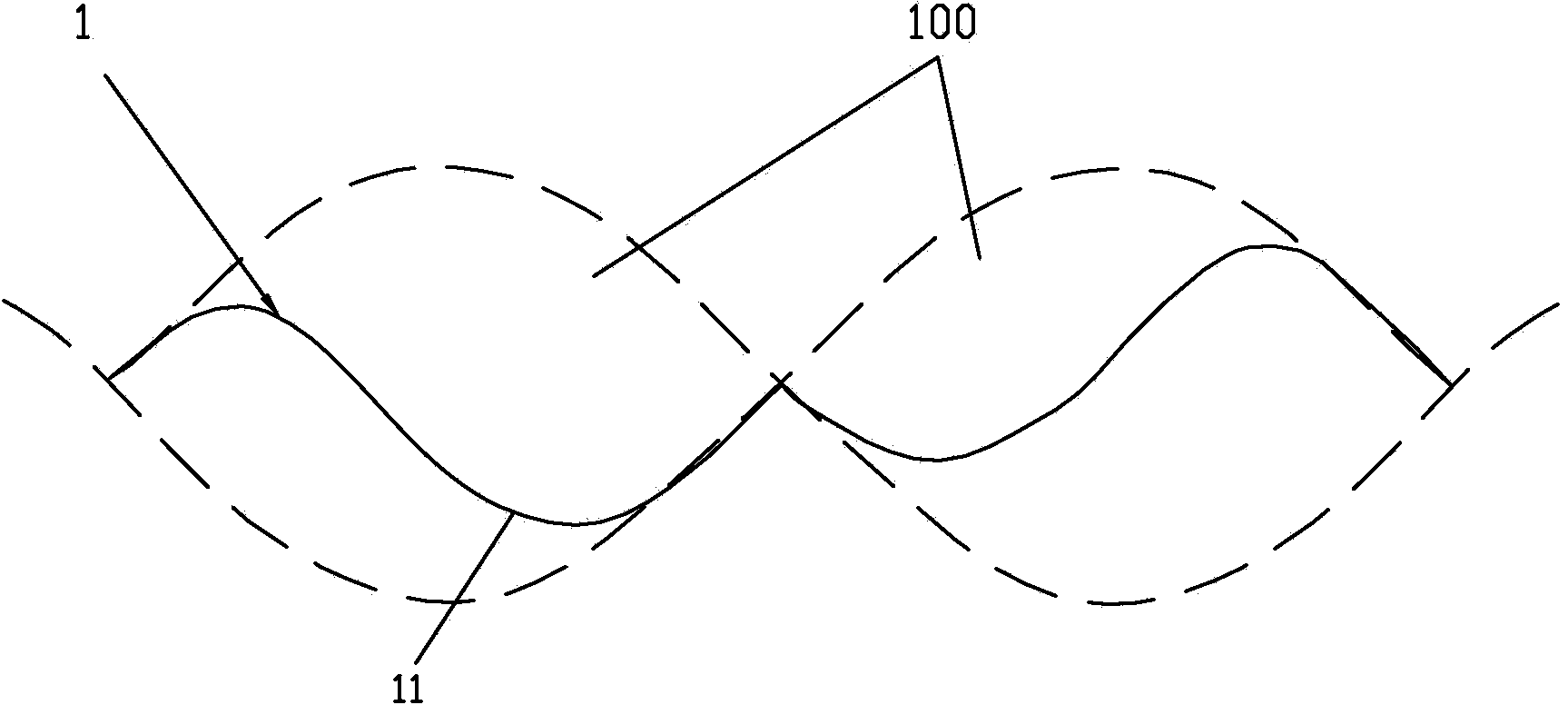

[0021] see figure 1 , figure 2 , a monofilament wire saw wire of the present invention, the wire saw wire 1 is distributed along the axial direction to form several periodic bending parts 11, and each bending part is not in a plane, and is continuously deflected along the axial direction, deflected The angle starts from 0 degrees, deflects to angle A and then reverses to -A degrees, and then reverses to 0 degrees to complete a cycle. The range of deflection angle A can be between 0 and 180 degrees.

[0022] Further, the outer envelope diameter D of the curved portion 11 of the wire saw wire 1 is 1.01 to 2 times the diameter of the monofilament steel wire, such as figure 2 As shown, 100 is the elliptical spherical deformation space of the sawing wire. The steel wire sawing wire has periodic deformation characteristics. In each period, the deformed steel wire forms multiple bending parts, and the spatial structure is continuous within the spatial range. At the same time, due ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com