Method for treating rolling emulsification wastewater through electrocoagulation

A technology for emulsification of wastewater and electrocoagulation, which is applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of polluting ground water bodies and groundwater sources, destroying the ecological environment, and difficult to treat wastewater. , to achieve the effect of excellent demulsification effect, easy operation and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] After filtering the emulsified rolling waste water, pump it into the electrolytic cell (the electric plate of the electrolytic cell is an aluminum plate with a surface area of 116cm2, with a distance of 1cm, and the anode and cathode plates are distributed in multiple groups in the electrolytic cell), and at the same time, add 1.25g to the electrolytic cell / L electrolyte sodium chloride, and adjust the PH value of the wastewater to 6.0, pass a direct current with a current intensity of 4mA / cm2 into the electrolytic cell, after the electrolysis reaction for 40 minutes, let it stand for 1 hour and scrape off the suspended oil on the liquid surface , the discharged supernatant water is the treated drainage.

Embodiment 2

[0016] Embodiment two: processing effect

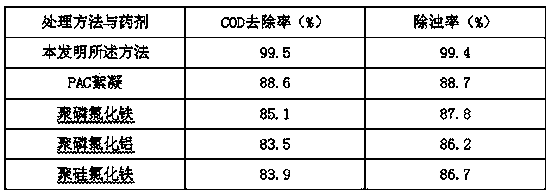

[0017] Using the method of electrocoagulation treatment of rolling emulsified wastewater according to the present invention, a certain rolling emulsified wastewater is treated, and compared with the chemical flocculation method, the treatment effect is shown in Table-1.

[0018] Table-1 Treatment effect

[0019]

[0020] It can be seen from Table-1 that the electrocoagulation treatment effect of the present invention is better than that of chemical flocculation, the COD removal rate of wastewater reaches 99.5%, and the turbidity removal rate reaches 99.6%. The reason may be that (1) the flocculation effect of the new ecological polyaluminum chloride produced by electrolysis is better, and (2) the ClO-oxidant produced by the electrode reaction can oxidize the organic matter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com