Method and device for preparing methyl fluoroacetate

A technology of methyl fluoroacetate and methyl chloroacetate, which is applied in the preparation of methyl fluoroacetate and the field of equipment for preparing methyl fluoroacetate, can solve the problems of low purity and yield of methyl fluoroacetate, and improve the reaction conversion The efficiency, the process is simple and reasonable, and the effect of improving the reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

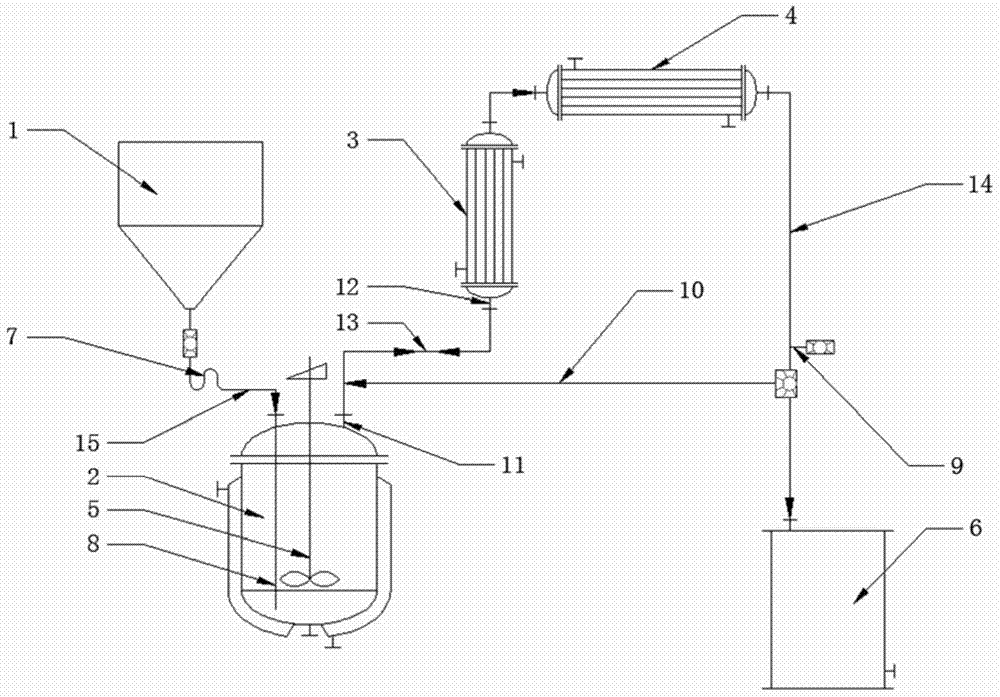

[0025] The preparation method of the methyl fluoroacetate of present embodiment, comprises the following steps:

[0026] 1) Add 223kg of potassium fluoride, 494kg of dimethylformamide (DMF), 333kg of acetamide and 10kg of catalyst dodecyltrimethylammonium bromide into the reaction kettle. Under normal pressure, start the stirring tank to stir, and heat up;

[0027] 2) Add 434 kg of methyl chloroacetate into the raw material storage tank. When the temperature of the reactor rises to 100°C, continue to add methyl chloroacetate into the reactor at a rate of 10 kg / min for reaction, and at the same time condense the two Condensed water is fed into the condenser respectively, and the mixed gas generated by the reaction enters the two-stage condenser for two-stage condensation;

[0028] 3) According to the difference in boiling point temperature, methyl chloroacetate and methyl fluoroacetate in the mixed gas are condensed in the first and second condensers of the two-stage condenser...

Embodiment 2

[0034] The preparation method of the methyl fluoroacetate of present embodiment, comprises the following steps:

[0035] 1) Add 500kg of potassium fluoride, 700kg of dimethylformamide (DMF), 500kg of acetamide and 20kg of catalyst tetrabutylammonium chloride into the reaction kettle. Under normal pressure, start the stirring tank to stir and raise the temperature;

[0036] 2) Add 1000kg of methyl chloroacetate to the raw material storage tank. When the temperature of the reactor rises to 160°C, continue to add methyl chloroacetate into the reactor at a rate of 5kg / min for reaction, and simultaneously condense the two Condensed water is fed into the condenser respectively, and the mixed gas generated by the reaction enters the two-stage condenser for two-stage condensation;

[0037]3) According to the difference in boiling point temperature, methyl chloroacetate and methyl fluoroacetate in the mixed gas are condensed in the first and second condensers of the two-stage condenser...

Embodiment 3

[0041] The preparation method of the methyl fluoroacetate of present embodiment, comprises the following steps:

[0042] 1) Add 1000kg of potassium fluoride, 800kg of dimethylformamide (DMF), 500kg of acetamide and 30kg of catalyst tetrabutylammonium bromide into the reaction kettle. Under normal pressure, turn on the stirring tank to stir and raise the temperature;

[0043] 2) Add 1000kg of methyl chloroacetate to the raw material storage tank. When the temperature of the reactor rises to 130°C, continue to add methyl chloroacetate into the reactor at a rate of 10kg / min for reaction. At the same time, the two-stage condensation Condensed water is fed into the condenser respectively, and the mixed gas generated by the reaction enters the two-stage condenser for two-stage condensation;

[0044] 3) According to the difference in boiling point temperature, methyl chloroacetate and methyl fluoroacetate in the mixed gas are condensed in the first and second condensers of the two-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com