Microencapsulated daily use essence and preparation method thereof

A technology for microcapsules and daily use, which is applied in the direction of microcapsule preparation, preparation of microspheres, essential oils/fragrances, etc. It can solve the problems of poor stability of microcapsule daily essences, and achieve the purpose of prolonging the fragrance retention time, ensuring safety, and system stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

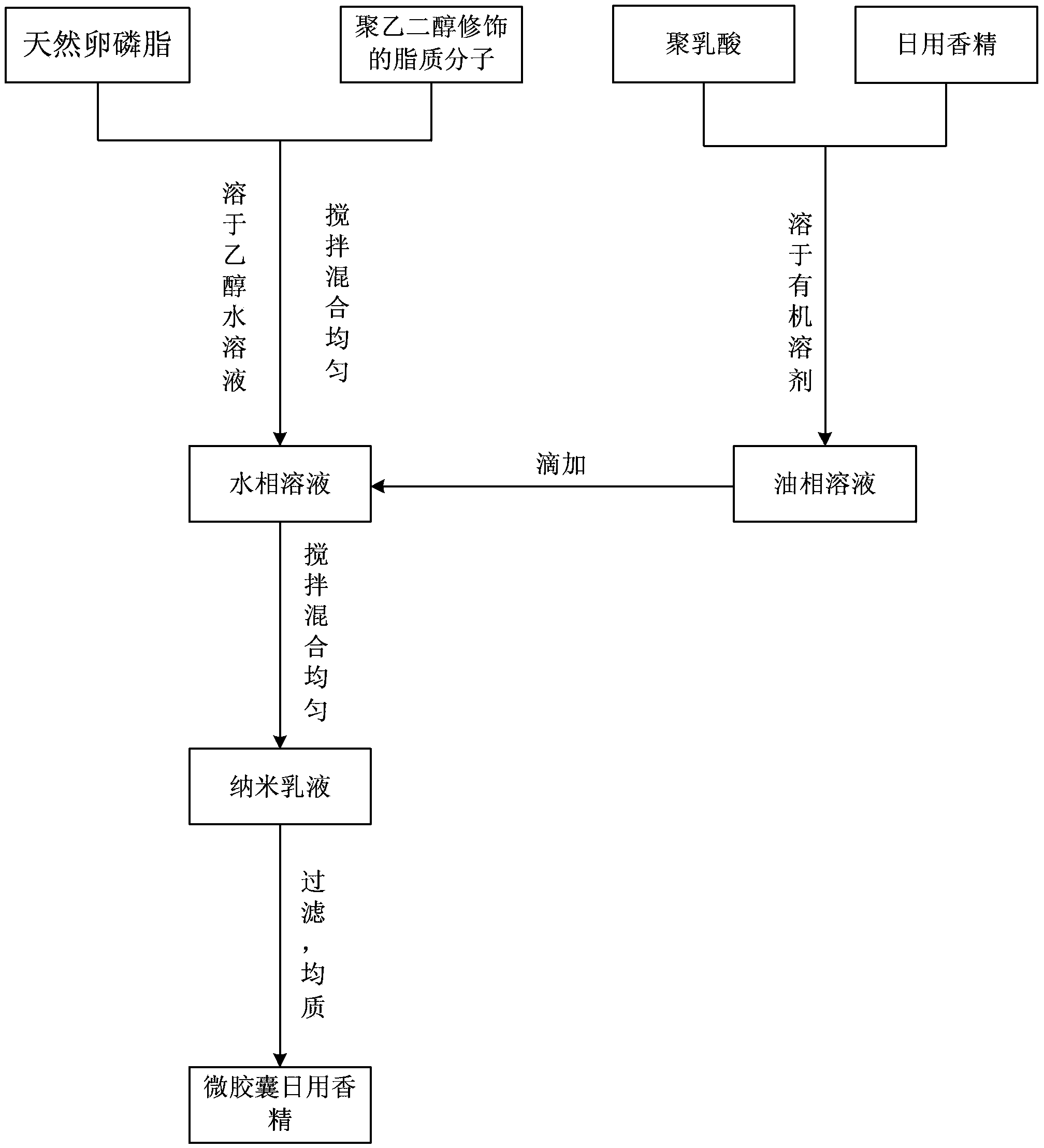

Image

Examples

Embodiment 1

[0065] A kind of microcapsule daily essence, its preparation method comprises the following steps:

[0066] (1) Dissolve 3.19mg of soybean lecithin and 1.31mg of polyethylene glycol-distearoylphosphatidylethanolamine (PEG-DSPE) in 30mL of ethanol solution (volume fraction of ethanol is 4%), and heat in a water bath , stirred evenly by magnetic force until completely dissolved to form a transparent solution, and an aqueous phase solution containing lipid components was obtained;

[0067] In the aqueous phase solution, the molar ratio of soybean lecithin and PEG-DSPE is 9:1; the concentration of lipid components (soybean lecithin and PEG-DSPE) is 0.15 mg / mL;

[0068] (2) Dissolve 25.5mg of polylactic acid (PLGA) and 15mg of daily oil-soluble rose essence into 8.1mL of tetrahydrofuran solution, and magnetically stir until completely dissolved to obtain an oil phase solution;

[0069] The mass ratio of the PLGA to the lipid component is 8.5:1.5; the mass ratio of the daily essenc...

Embodiment 2

[0074] A kind of microcapsule daily essence, its preparation method comprises the following steps:

[0075] (1) Dissolve 2.73mg of soybean lecithin and 1.78mg of polyethylene glycol-distearoylphosphatidylethanolamine (PEG-DSPE) in 30mL of ethanol solution (volume fraction of ethanol is 4%), and heat in a water bath , stirred evenly by magnetic force until completely dissolved to form a transparent solution, and an aqueous phase solution containing lipid components was obtained;

[0076] In the aqueous phase solution, the molar ratio of soybean lecithin and PEG-DSPE is 8.5:1.5; the concentration of lipid components (soybean lecithin and PEG-DSPE) is 0.15mg / mL;

[0077](2) Dissolve 25.5mg of polylactic acid (PLGA) and 15mg of daily oil-soluble rose essence into 8.1mL of tetrahydrofuran solution, and magnetically stir until completely dissolved to obtain an oil phase solution;

[0078] The mass ratio of the PLGA to the lipid component is 8.5:1.5; the mass ratio of the daily esse...

Embodiment 3

[0083] A kind of microcapsule daily essence, its preparation method comprises the following steps:

[0084] (1) Dissolve 1.3mg of soybean lecithin and 3.2mg of polyethylene glycol-distearoylphosphatidylethanolamine (PEG-DSPE) in 30mL of ethanol solution (volume fraction of ethanol is 4%), and heat in a water bath , stirred evenly by magnetic force until completely dissolved to form a transparent solution, and an aqueous phase solution containing lipid components was obtained;

[0085] In the aqueous phase solution, the molar ratio of soybean lecithin and PEG-DSPE is 6:4; the concentration of lipid components (soybean lecithin and PEG-DSPE) is 0.15 mg / mL;

[0086] (2) Dissolve 25.5mg of polylactic acid (PLGA) and 15mg of daily oil-soluble rose essence into 8.1mL of tetrahydrofuran solution, and magnetically stir until completely dissolved to obtain an oil phase solution;

[0087] The mass ratio of the PLGA to the lipid component is 8.5:1.5; the mass ratio of the daily essence ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com