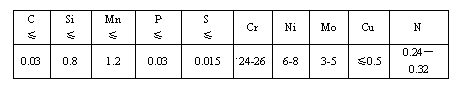

Duplex stainless steel forging and molding process

A duplex stainless steel, forging forming technology, applied in the field of forging, can solve the problems of crack propagation, easy cracking, high hardness and easy cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A duplex stainless steel forging forming process comprises the following steps:

[0021] The first step: inspect and cut the duplex stainless steel raw materials to obtain a 2.5t square steel ingot with a riser.

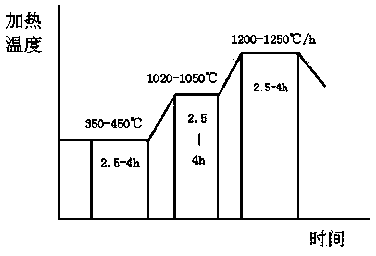

[0022] Step 2: Put the steel ingot into a furnace at 350°C to heat and keep it warm for 2.5 hours. Take 6 hours to raise the temperature of the steel ingot at 350°C to 1020°C at a rate of 90°C / h and keep it warm for 2.5 hours.

[0023] Step 3: Take 2 hours to raise the temperature of the steel ingot at 1020°C to 1200°C at a rate of 70°C / h, and keep it warm for 2.5 hours.

[0024] Step 4: Upsetting the steel ingot vertically, pause for 2s every time the upper anvil of the press is pressed down by 30mm, round the upper anvil of the press once every time it is pressed down by 100mm, and then continue upsetting to the required size Φ1015*305 (diameter*height), flatten the end surface, Get round.

[0025] Step 5: Put the forged billet obt...

Embodiment 2

[0028] A duplex stainless steel forging forming process, comprising the following steps:

[0029] The first step: inspect and cut the duplex stainless steel raw materials to obtain a 2.5t square steel ingot with a riser.

[0030] Step 2: Put the steel ingot into a furnace at 450°C to heat and keep it warm for 4 hours, then use 6.5 hours to raise the temperature of the steel ingot at 450°C to 1050°C at a rate of 100°C / h, and keep it warm for 4 hours;

[0031] Step 3: Take 2.5 hours to raise the temperature of the steel ingot at 1050°C to 1250°C at a rate of 100°C / h, and keep it warm for 3.5 hours.

[0032] Step 4: Upsetting the steel ingot vertically, pause for 2 seconds every time the upper anvil of the press is pressed down by 35mm, roll the upper anvil of the press once every 150mm, and then continue upsetting to the required size Φ810*290 (diameter*height).

[0033] Step 5: Put the steel ingot obtained from the forging step in the fourth step into the furnace for 15 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com