Open-width alkali deweighting machine

An alkali reduction and open-width technology, applied in the field of alkali reduction machines, can solve the problems of high energy consumption, low efficiency, and high labor costs, and achieve the effects of uniform water temperature, soft and comfortable hand feeling, and reduced labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

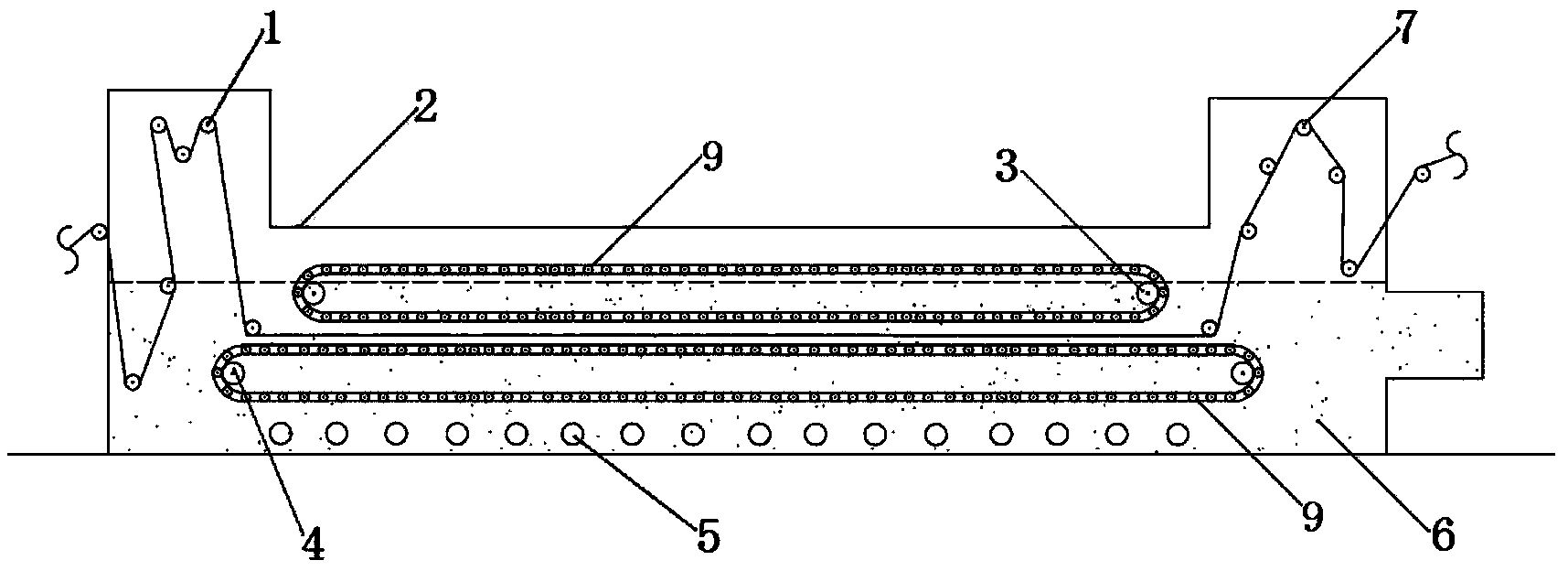

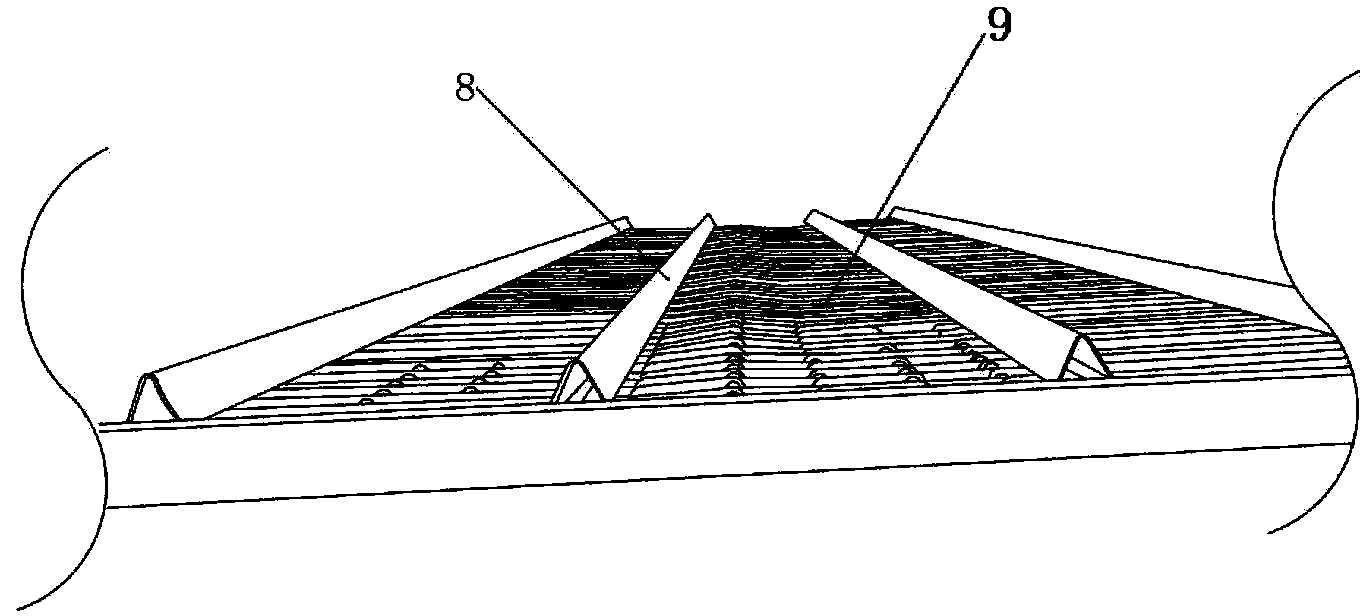

[0009] Refer to the accompanying drawings of the instruction manual: the cabinet body 2 is provided with a cloth feeding device 1 and a cloth discharging device 7, a treatment solution heater 5, a treatment solution 6, and a downward pressure transmission crawler 3 and a gray cloth transmission crawler 4 used in conjunction with the upper and lower sides, and the cloth feeding device 1 And the cloth outlet device 7 is made up of the guide roller that adjusts the running speed of the flat gray cloth, changes the cloth feeding and cloth outlet way of the rope-shaped gray cloth in the past, and presses down the conveying crawler belt 3 and the gray cloth conveying crawler belt 4 respectively by respective crawler belt 9 and driving shaft Composition, the crawler belt 9 that presses down the conveying belt 3 is located at the lower part and is set under the liquid surface of the treatment solution 6 in the cabinet, so that the gray cloth can be fully contacted and heated on the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com