Installation and maintenance well at the junction of leachate drainage pipe and dam-piercing pipe and its construction method

A technology for dam-piercing pipes and maintenance wells, applied in artificial islands, water conservancy projects, water supply devices, etc., can solve problems such as blockage of dam-piercing pipes, difficulty in welding quality assurance, inconvenient inspection and maintenance, etc., to avoid tearing and displacement The effect of reducing and facilitating inspection and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

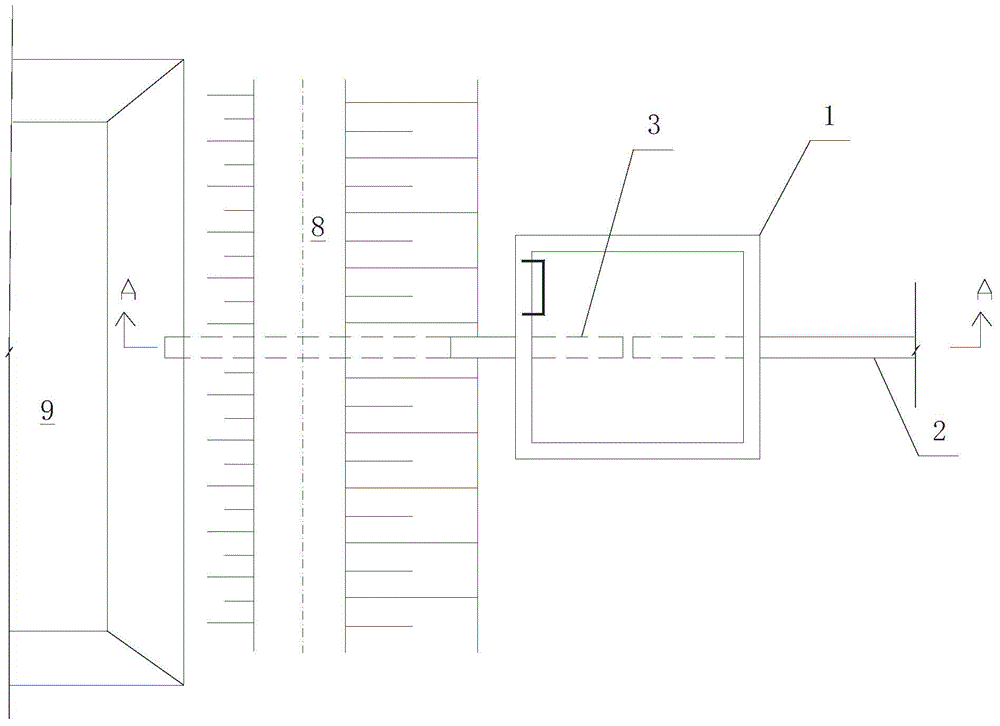

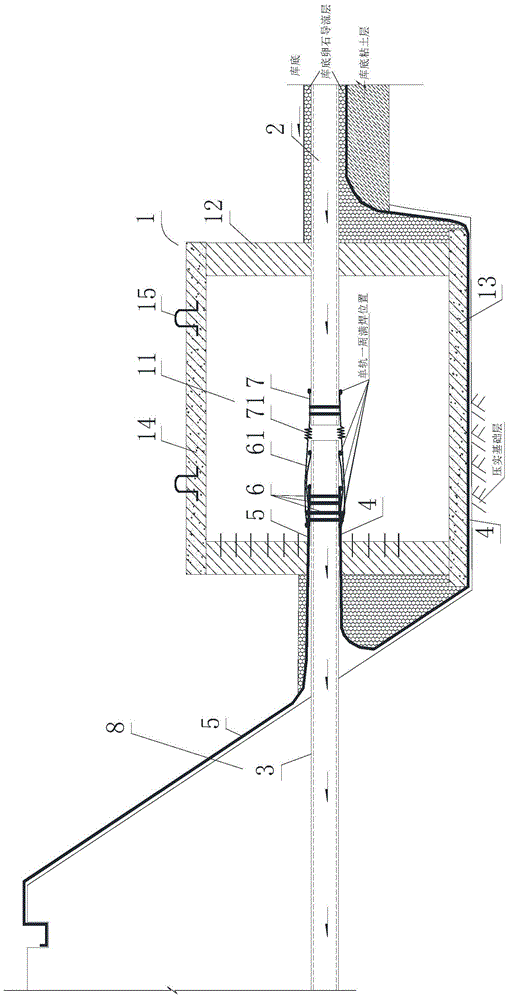

[0039] a kind of like figure 1 , figure 2 Shown is the installation and maintenance well of the solid waste treatment site of the present invention (this embodiment is a landfill) at the junction of the leachate guide pipe and the dam-piercing pipe. The installation and maintenance well includes the installation and maintenance well body 1 and extends to the installation and maintenance The leachate drainage pipe 2 and the dam piercing pipe 3 in the well body 1, the leachate drainage pipe 2 in this embodiment is the leachate drainage supervisor at the bottom of the landfill, mainly collecting the solid waste treatment Landfill leachate, etc. generated in the field, the dam-piercing pipe 3 in this embodiment is a connecting pipe connecting the leachate drainage pipe 2 and the regulating tank 9, which mainly collects the landfill leachate, etc. collected in the leachate drainage pipe 2 Exported to the regulating pool 9 outside the solid waste treatment site, the installation m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com