Single-cylinder two-stroke water-cooled engine

A water-cooled engine, two-stroke technology, applied to engine components, machines/engines, cylinders, etc., can solve the problems of low speed, large volume, low power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

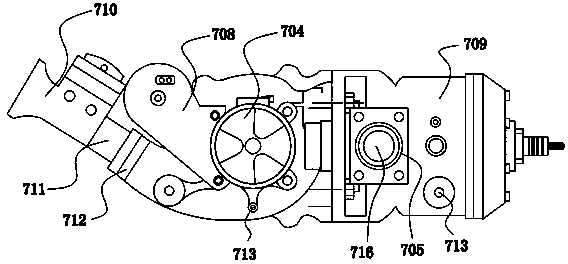

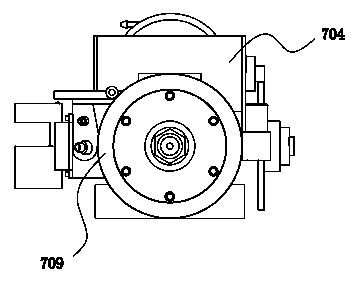

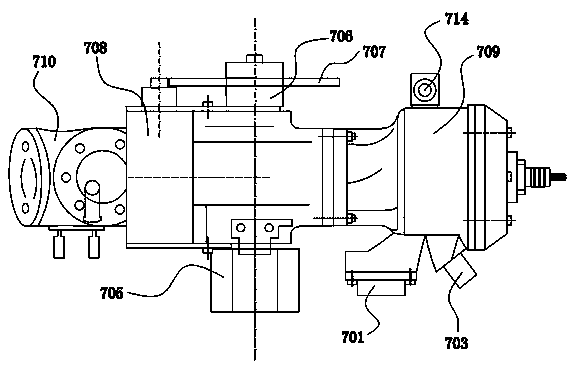

[0018] See attached Figures 1 to 3 , the single-cylinder two-stroke water-cooled engine in the figure includes a crankcase 704, a starter motor 708, a carburetor 710 and an engine cylinder 709; wherein: the other end of the crankshaft output end of the crankcase 704 is fixed with a one-way bearing 706. A reduction gear 707 is installed on the bearing 706, and the reduction gear 707 meshes with the driving gear on the output shaft of the starter motor 708;

[0019] The centerline of the carburetor 710 forms an included angle of 30° with the centerline of the crankcase 704, and the centerline of the engine cylinder 709 coincides with the centerline of the crankcase 704; the starter motor 708 is located between the carburetor 710 and the crankshaft the corner between boxes 704;

[0020] The carburetor 710 communicates with the air inlet of the crankcase 704 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com