Water adapter

A water joint and body technology, applied in the field of water-cooled reactor structure design, can solve the problems of poor heat dissipation and high temperature rise of the water-cooled reactor, and achieve the effects of solving waterway blockage, uniform and stable accuracy, and improving utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

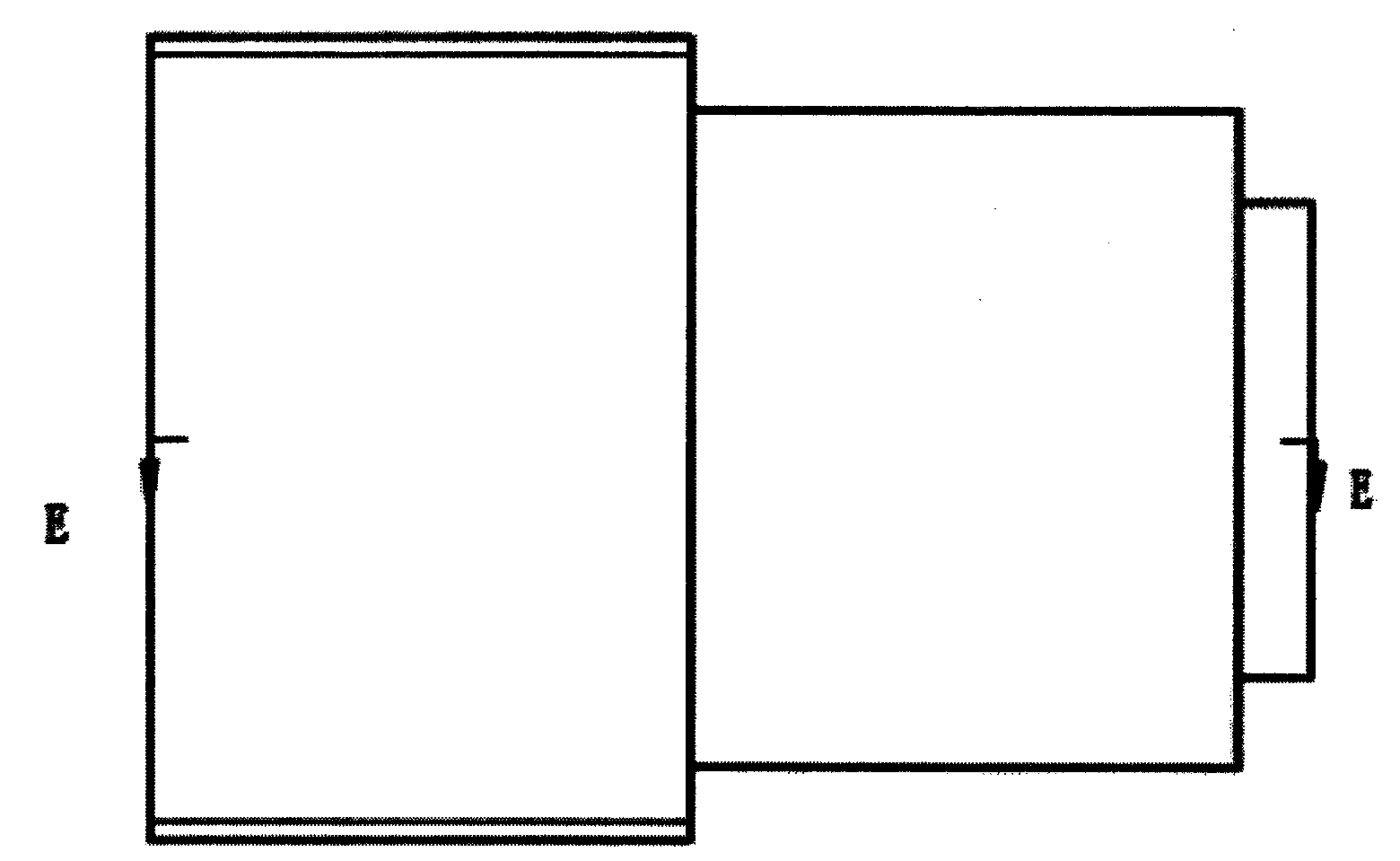

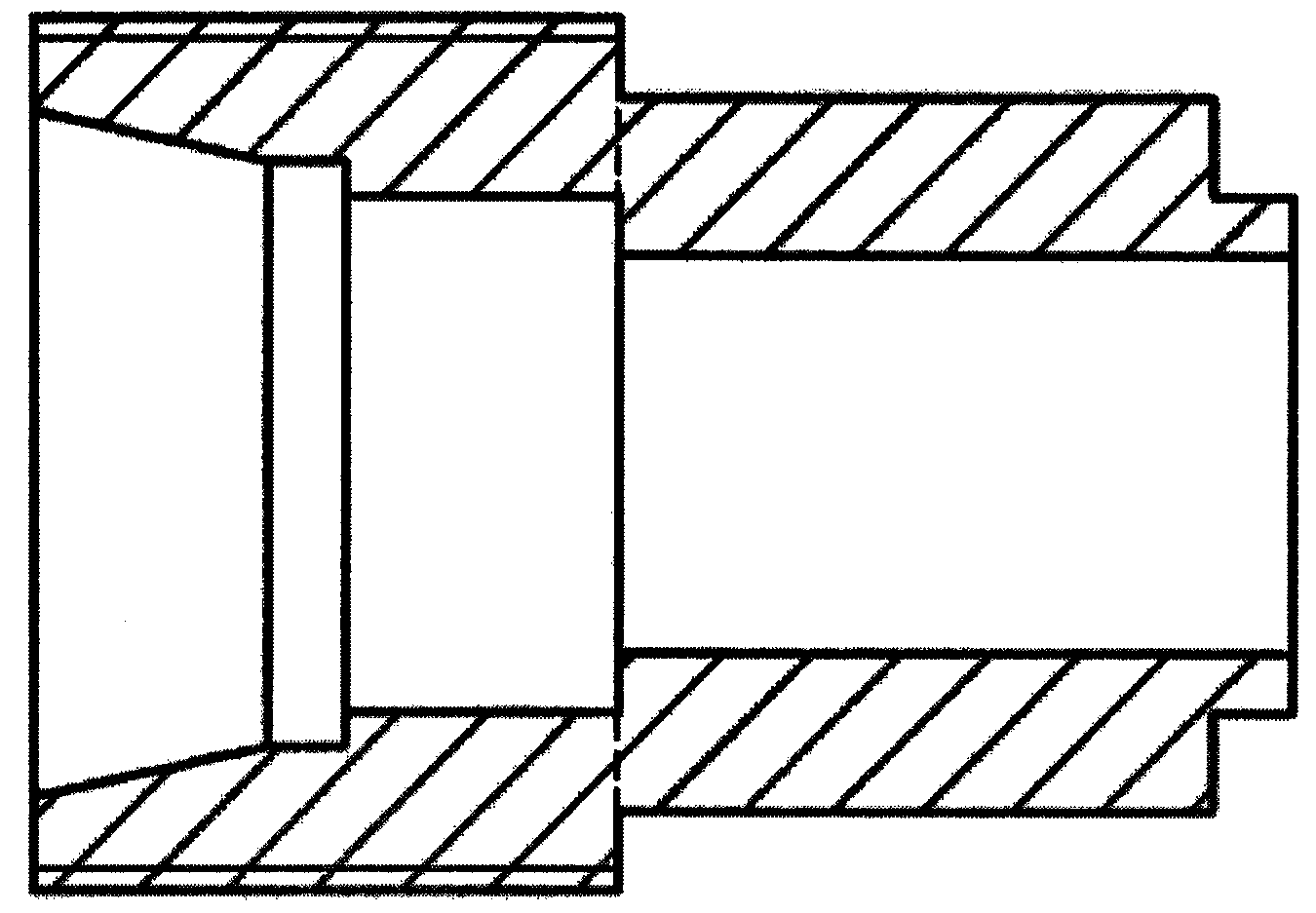

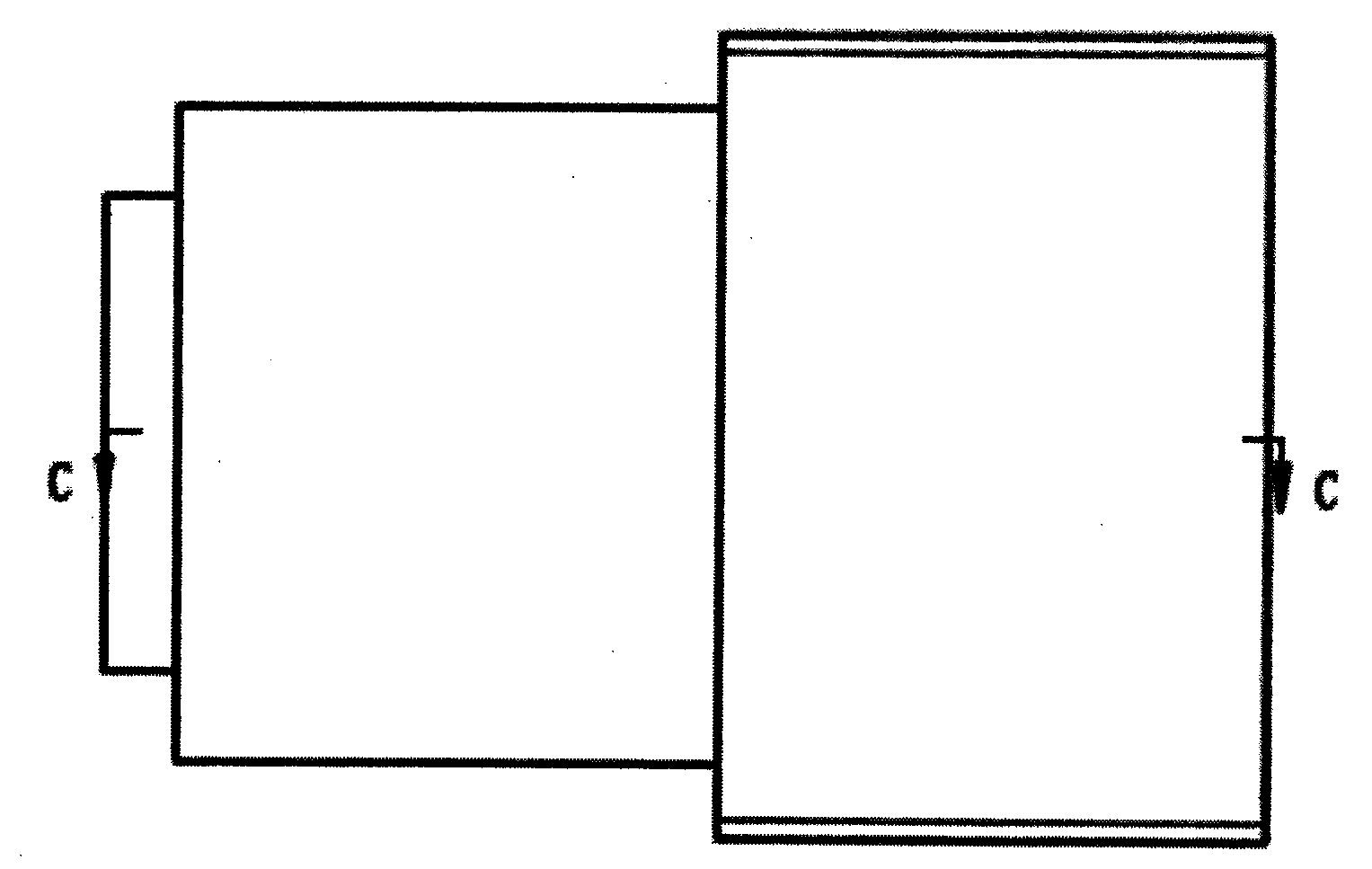

[0018] like image 3 and Figure 4 As shown, a water joint provided by the present invention includes a body 1 in which a coolant channel is formed. Stainless steel filter 2 through such as Figure 5 The shown elastic circlip 3 is fixed in the body 1, and the longitudinal section of the cooling liquid channel at its fixed position is completely covered by the stainless steel filter 2, the mesh number of which is 40 mesh to 100 mesh.

[0019] In the present invention, the presence of the stainless steel filter screen 2 and the elastic circlip 3 greatly protects the entire water system. When the cooling liquid flows through the stainless steel filter screen 2, the impurities therein will be blocked outside and cannot flow through the next process port with the cooling liquid. This has the effect of purifying the coolant, thereby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com