Automatic CCD product detecting device

An automatic detection device and product technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as hidden quality problems, large demand, and high labor intensity, and reduce the source of system errors and pixel capture positions Accurate and guarantee the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

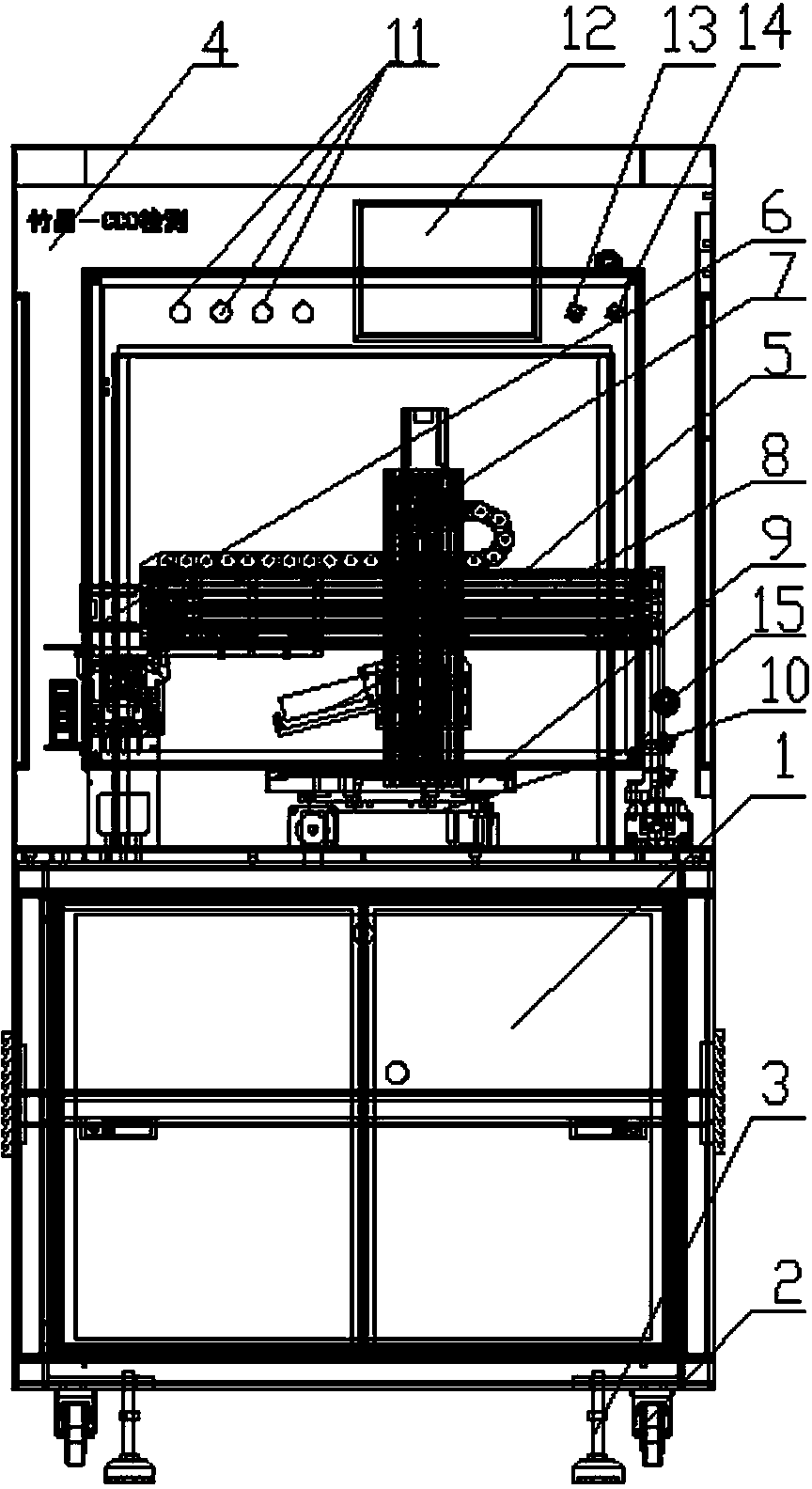

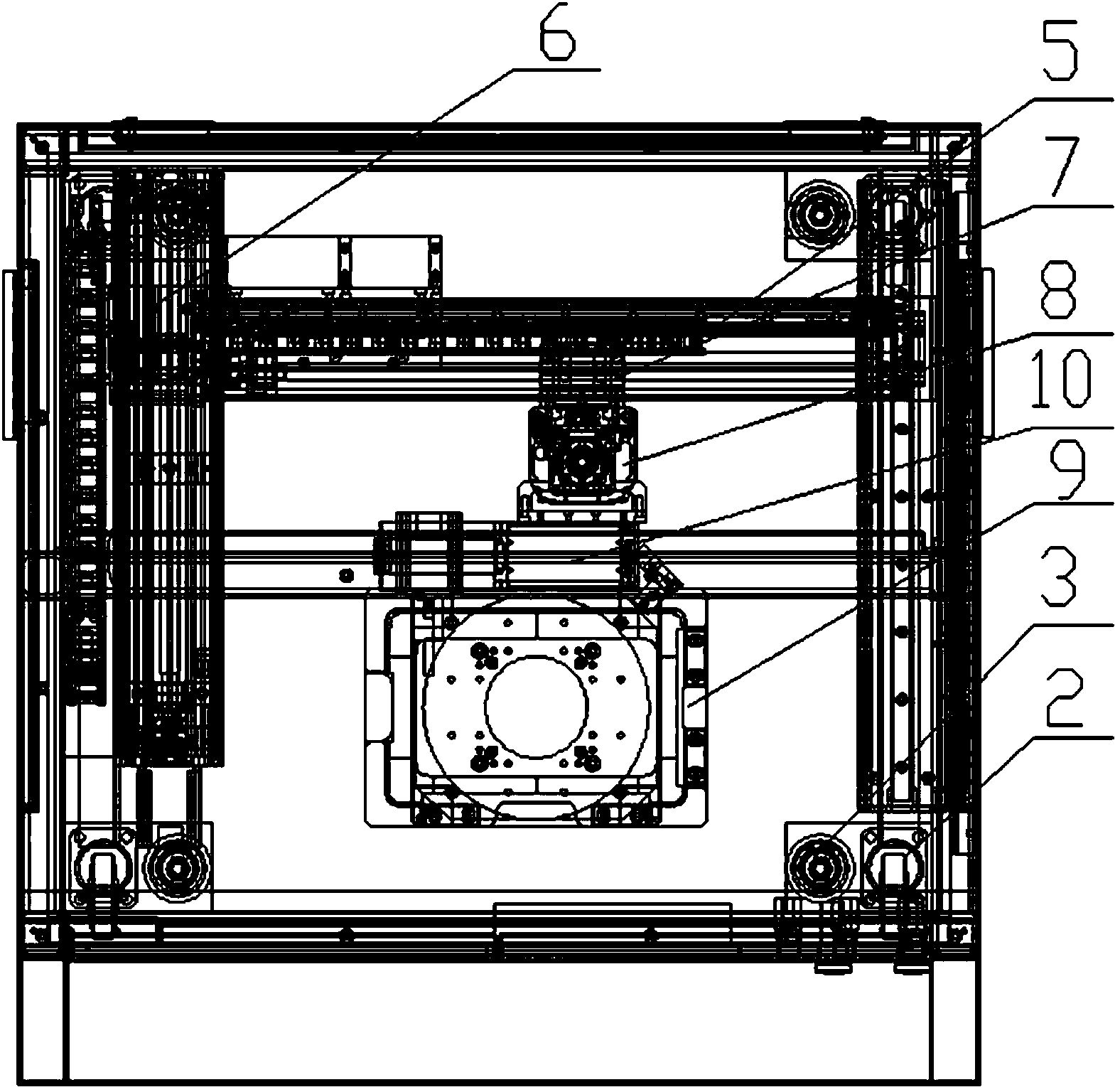

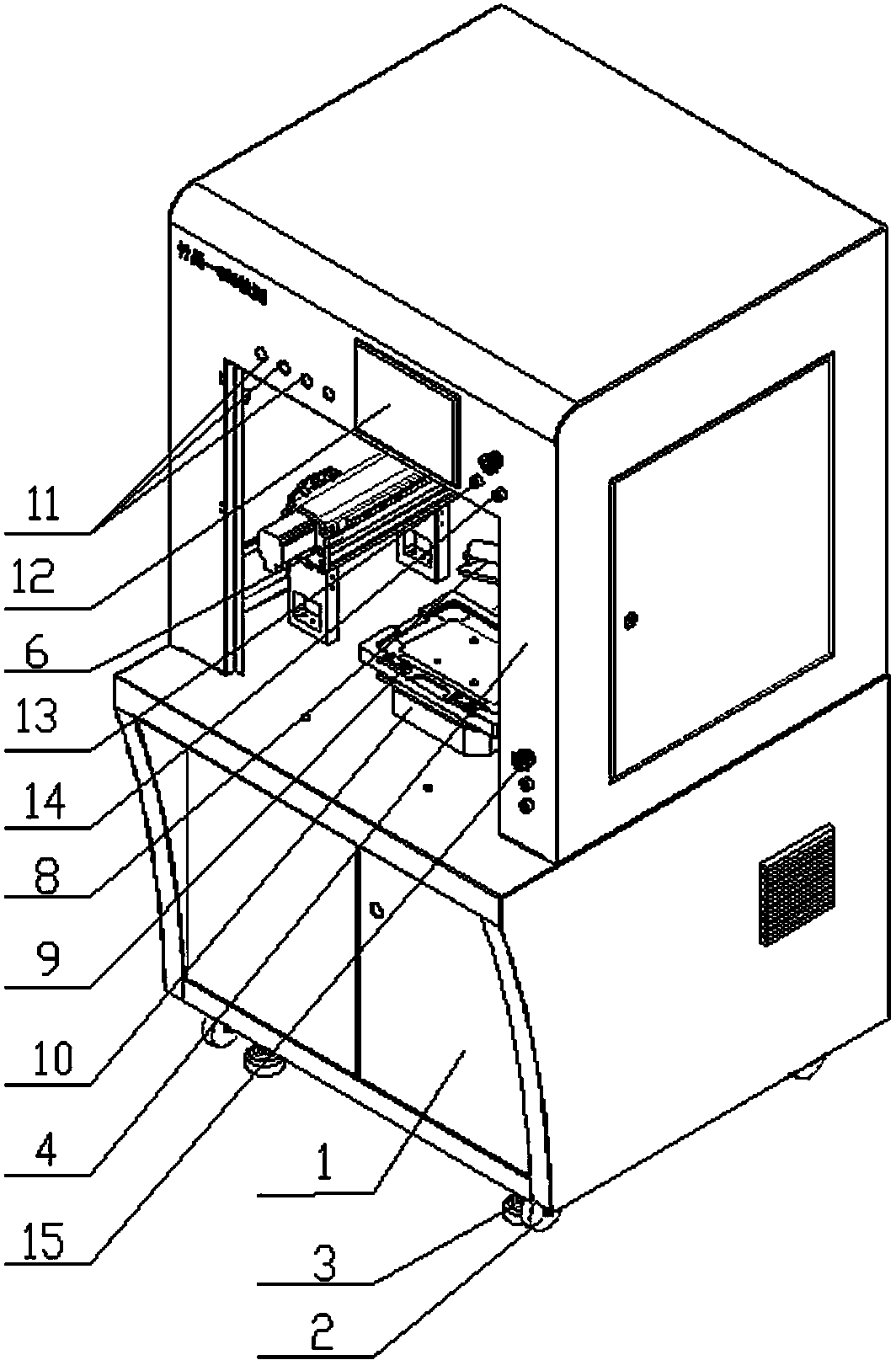

[0016] see Figure 1-3 , an automatic detection device for CCD products, comprising an electric control cabinet 1, a roller 2, a foot 3, an equipment cover 4, an X-axis assembly 5, a Y-axis assembly 6, a Z-axis assembly 7, a CCD intelligent vision system 8, fixtures 9 and R rotation axis 10, the electric control cabinet 1 is placed on the ground through the roller 2 and the feet 3, the equipment can move the position through the roller 2, the equipment cover 4 is installed on the electric control cabinet 1, and the upper left side of the equipment cover 4 is installed with a three-color Indicator light 11, three-color indicator light 11 reports to the police when accident occurs in the measurement process, and the equipment cover 4 on the right side of three-color indicator light 11 is equipped with touch screen 12, and the product size that measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com