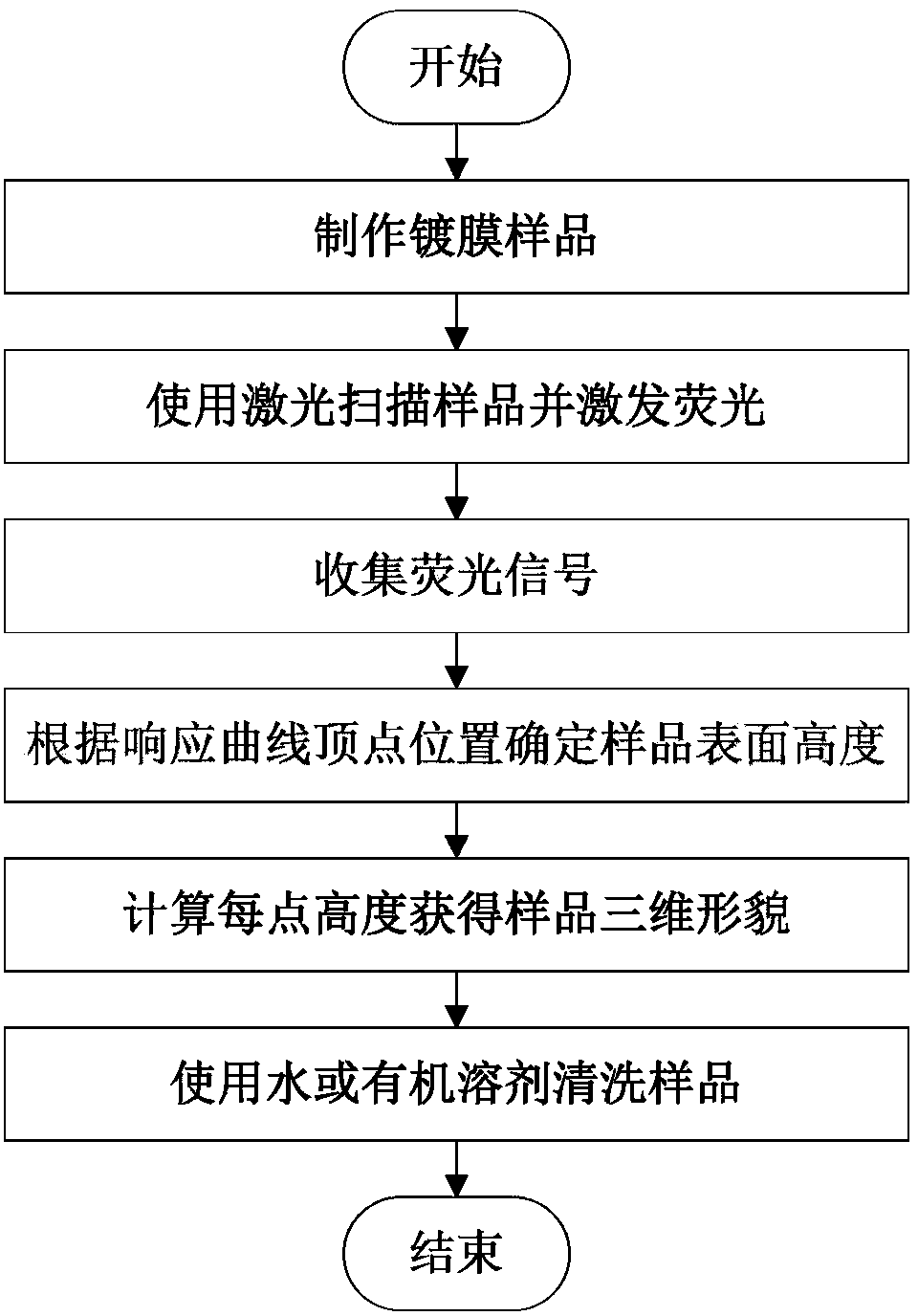

Smooth large-curvature sample measurement device and method based on fluorescent confocal microscopy

A confocal microscopy and measurement device technology, applied in measurement devices, fluorescence/phosphorescence, optical devices, etc., can solve problems such as decreased measurement resolution, inability to complete measurements accurately and efficiently, and inability to complete measurements, to improve measurement efficiency and save money. The steps of data fusion, the effect of avoiding uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

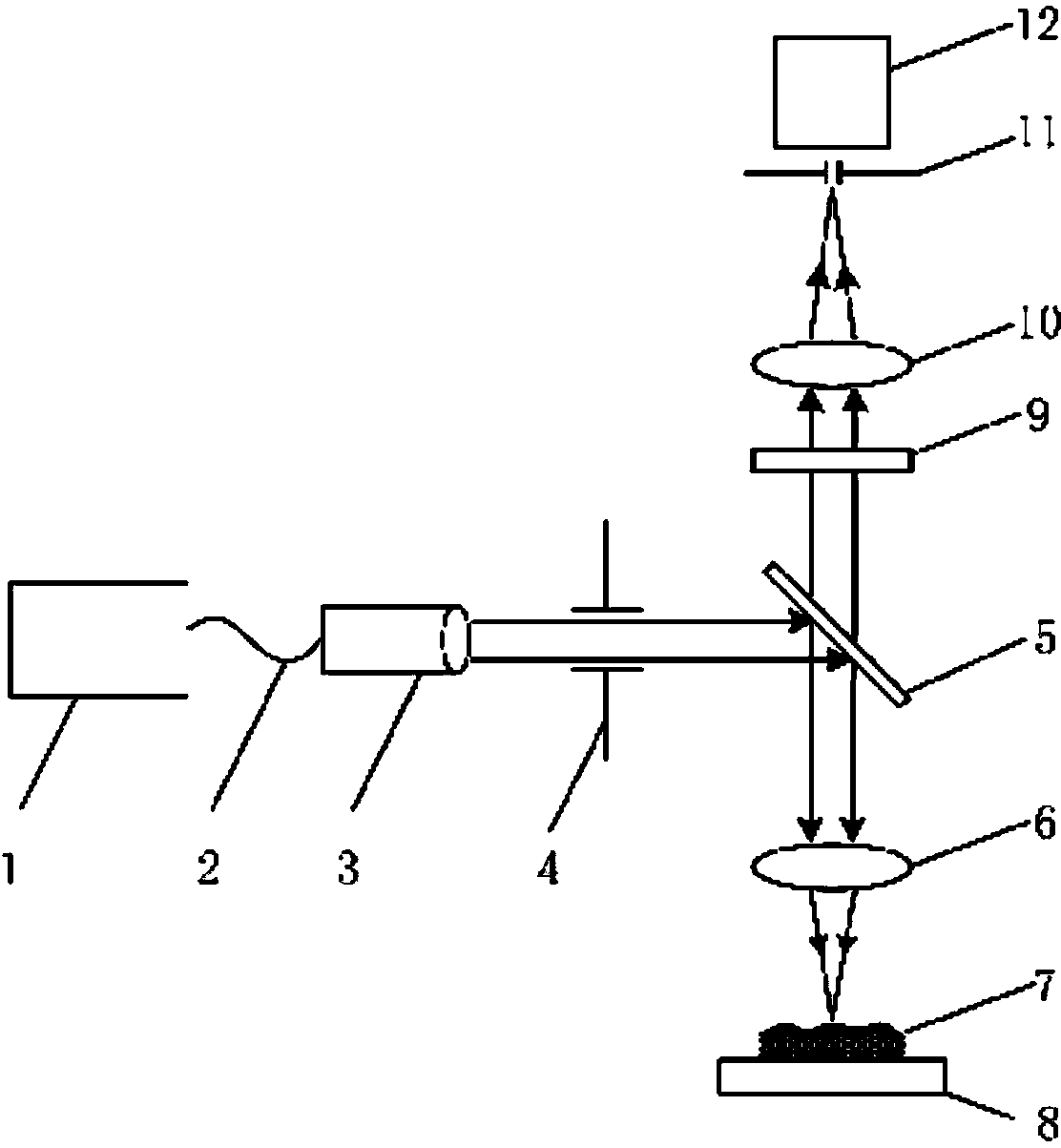

[0026] According to a specific embodiment of the present invention, a device for measuring smooth and large-curvature samples based on fluorescent confocal microscopy technology is provided, which is used for surface topography of smooth and large-curvature samples.

[0027] Please refer to figure 1 , figure 1 It is a schematic diagram of an embodiment of the measurement device for smooth and large curvature samples based on fluorescence confocal microscopy technology of the present invention. Such as figure 1 As shown, the smooth and large curvature sample measurement device based on fluorescence confocal microscopy technology includes: illumination module, detection module and coated sample. According to the direction of propagation of the illumination light, the lighting device is as follows: laser 1, conductive fiber 2, collimator 3, diaphragm 4, dichroic mirror 5, objective lens 6 and three-dimensional micro-displacement stage 8; the detection module follows the directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com