Sublevel caving/mining longwall face goaf flow filed simulation test device and method

A simulation test and goaf technology, applied in the direction of aerodynamic test, measuring device, machine/structural component test, etc., can solve the problem that the impact is not considered, can not be well matched, and the stress of the overlying stratum under the loading force does not exist Similarity and other issues, to achieve the effect of simple test method, good simulation effect and convenient observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing,

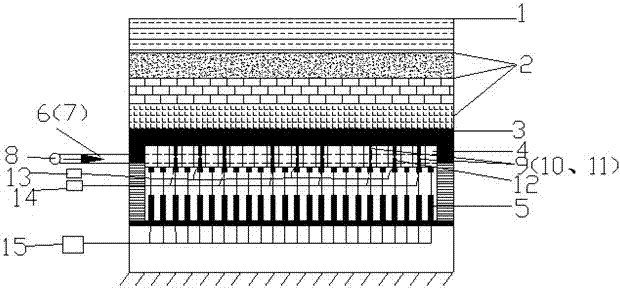

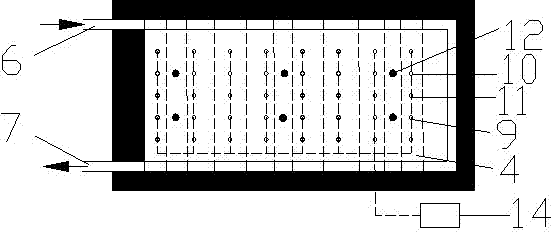

[0020] Such as figure 1 As shown, the goaf flow field simulation test device for fully mechanized caving / mining longwall working face of the present invention includes a test box 1 filled with a simulated coal seam, and the test box 1 is a tempered glass structure with a length, width and height It is 3800 mm × 2000 mm × 1500mm, the simulated coal seam is composed of the overlying rock layer 2 and the remaining coal seam 3, and a goaf flow field test system is provided under the simulated coal seam of the test model box, and the goaf flow field test system The system includes a hydraulic lifting device located at the bottom of the test chamber 1, the hydraulic lifting device includes a plurality of hydraulic lifting rods 5 arranged in a straight line and a hydraulic device starter 15 interconnected with the hydraulic lifting rods 5, the hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com