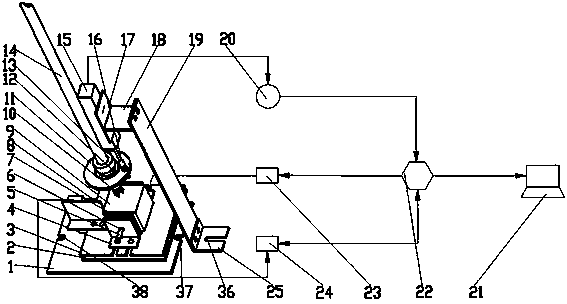

Shale crushing experimental device capable of considering drill string dynamic vibration and experimental method

An experimental device and drill string technology, applied in measuring devices, using repetitive force/pulse force to test material strength, instruments, etc., can solve problems such as difficulty in measuring drill string weight on bit, ROP, footage and torque, etc. Achieve the effect of improving drilling speed and wellbore quality, convenient operation and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] The device of the present invention is installed on a radial drilling machine for experiments, and the inclination angle of shale bedding is selected as 15°, and the specification length×width×height is 100mm×100mm×100mm.

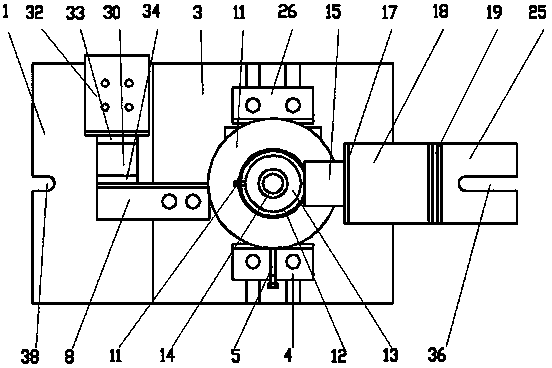

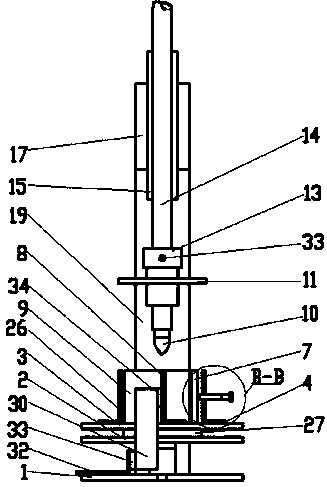

[0043] Step 1: Use a high-precision electronic scale to weigh 194.64g of the second-layer board 2 and all parts above it (the real WOB is the experimental weight-on-bit minus the weight of the second-layer board 2 and all parts above it), and make a record .

[0044] In the 2nd step, a miniature PDC drill bit 10 is installed at one end of drill string 14 tappings, and the inner ring surface of the rolling bearing 12 at the center of the plastic ring 11 is bonded to the outer circle of the "T" shape steel pipe 13, and the screw 35 passes through the "T" The threaded hole on the outer wall of the "shaped steel pipe 13 is rotatably connected to the outer wall of the fixed drill string 14, and the end of the drill string 14 without tapping is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com