PEA space charge measurement system and method under full-size high-voltage direct current cable temperature control gradient

A space charge and DC cable technology, applied in the direction of measuring devices, measuring electrical variables, instruments, etc., can solve problems such as difficult to ensure measurement and inconvenient measurement, and achieve measurement sensitivity and accuracy, excellent piezoelectric performance, and high resolution and the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

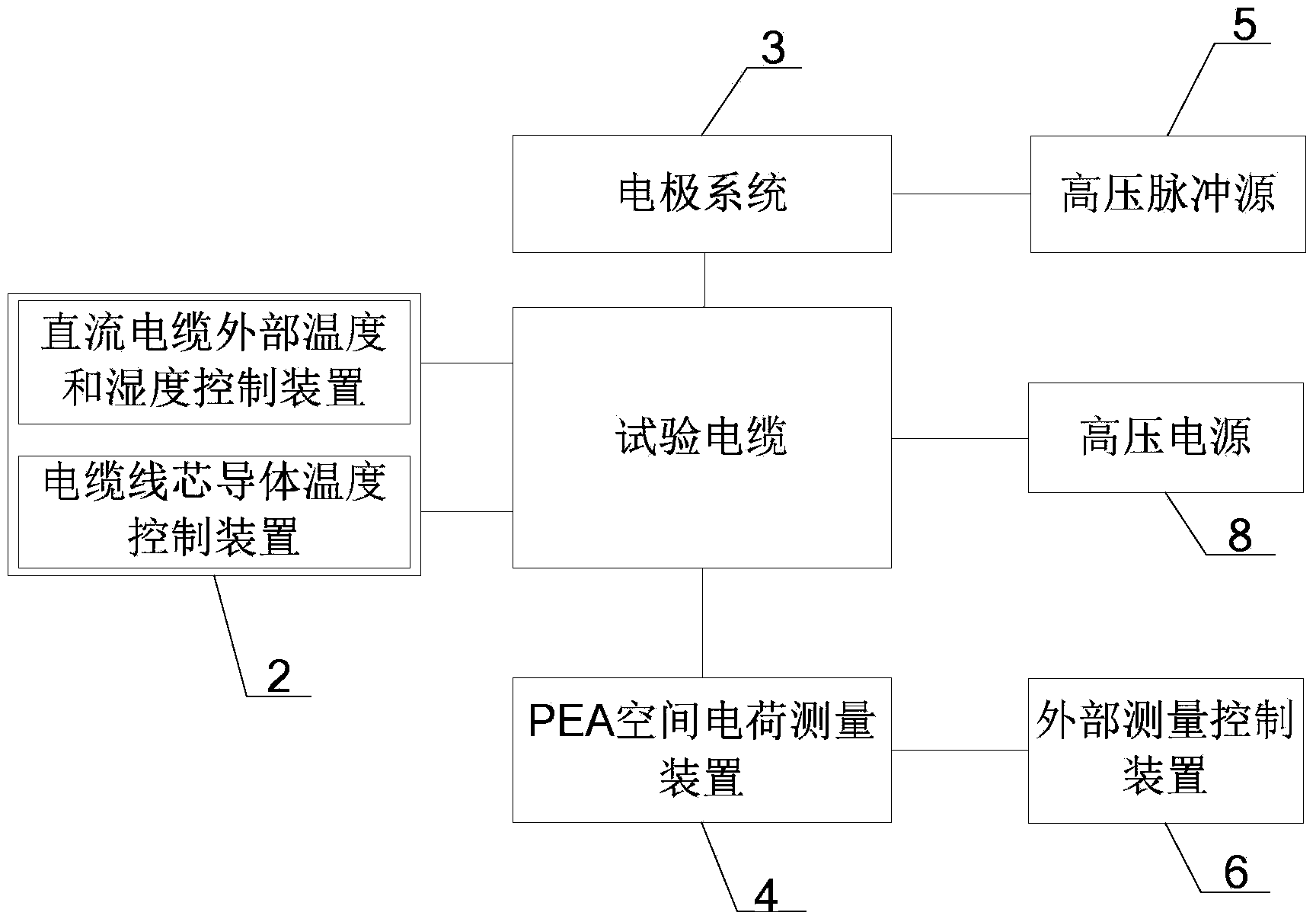

Method used

Image

Examples

Embodiment 4

[0097] Such as Figure 5 Shown is the flow chart of the PEA space charge measurement method of the embodiment of the present invention, including the following steps:

[0098] S1 Remove the cable outer sheath of the test cable measurement area to expose the outer semiconductive layer, then fix the test cable measurement area between the upper and lower electrodes, and keep the outer semiconductive layer in good contact with the upper and lower electrode surfaces;

[0099] S2 connects the test cable and the simulated cable respectively to form a closed loop;

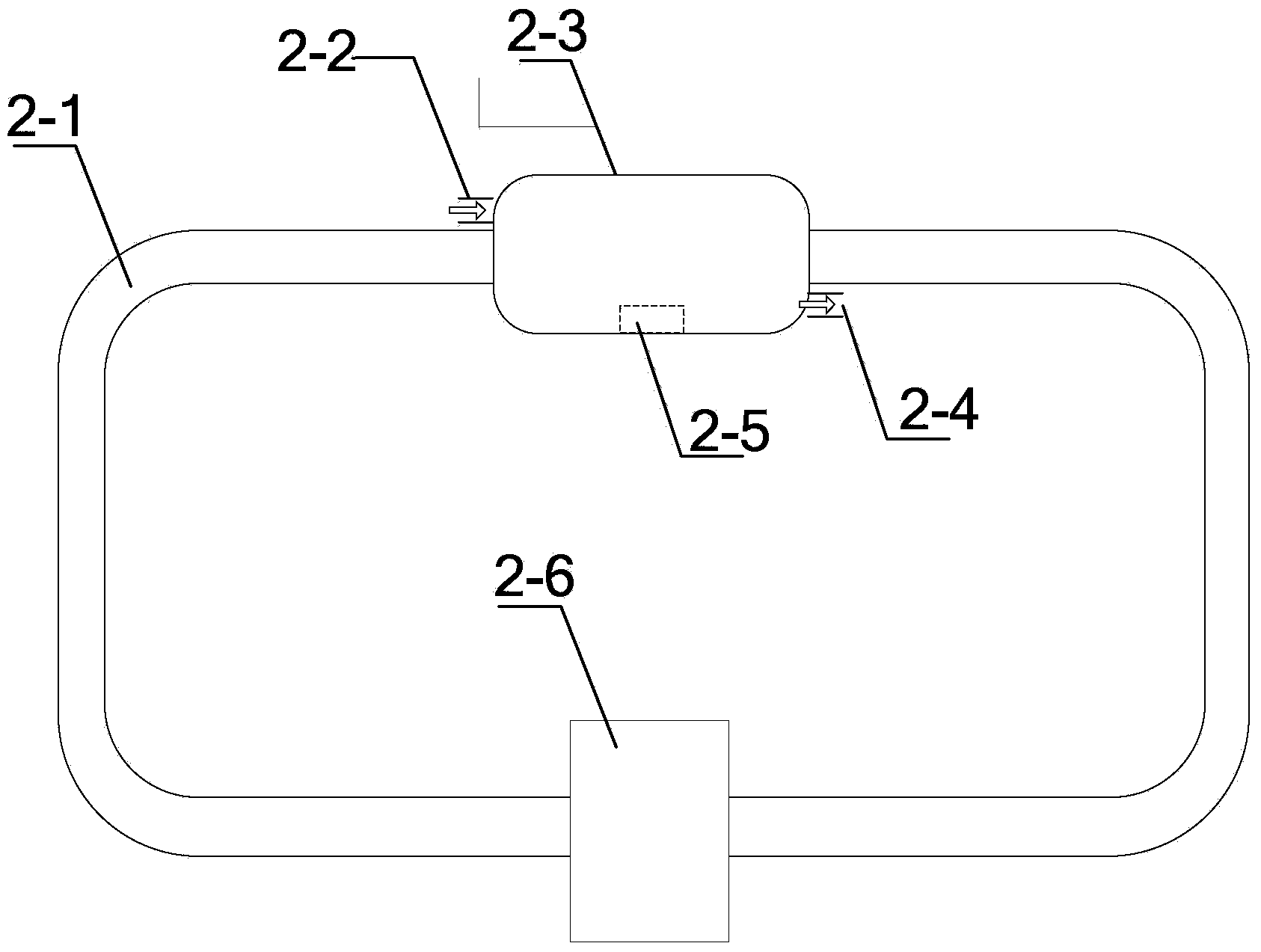

[0100] S3 Set up a DC cable insulation layer temperature gradient control device surrounding the outer semiconducting layer of the cable in the test cable measurement area;

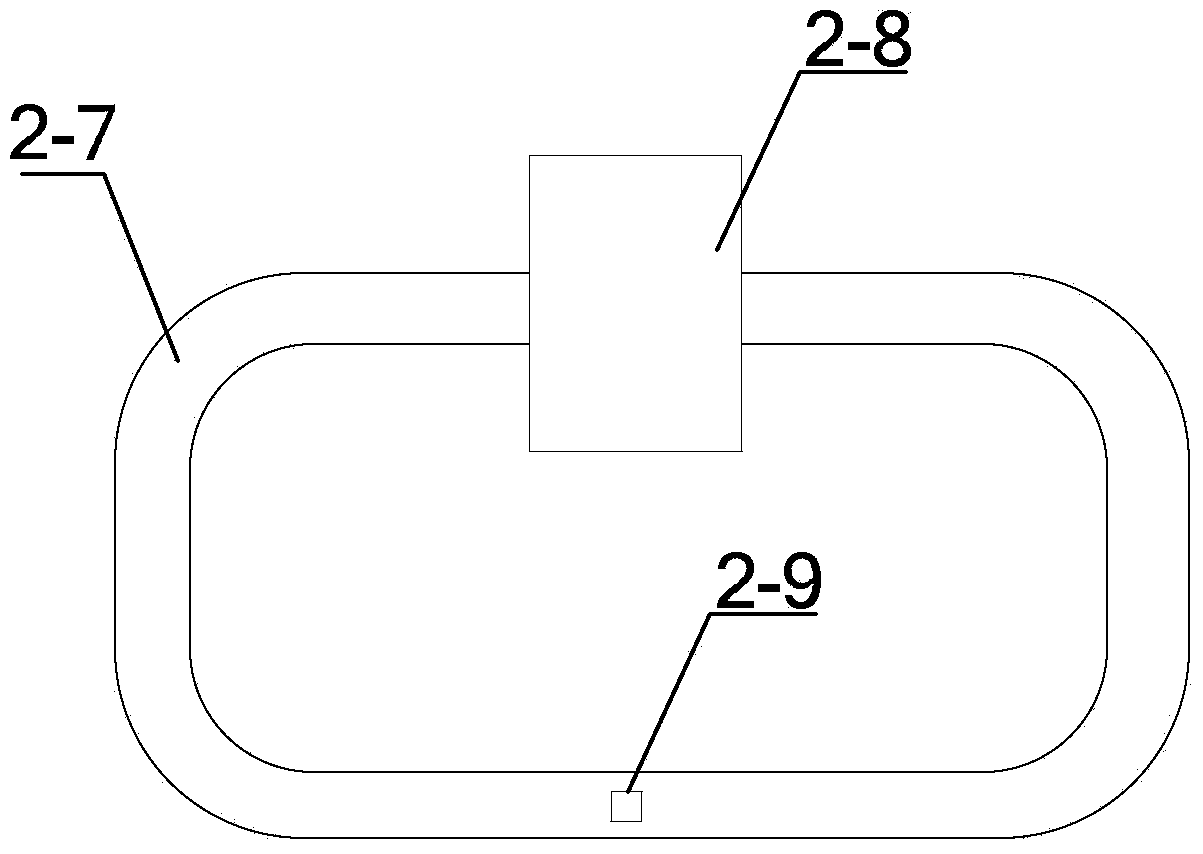

[0101] S4 adjusts the temperature of the DC cable core conductor, so that the test cable core conductor rises to the specified working temperature within the specified heating time;

[0102] S5 adjusts the temperature and humidity in the closed spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com