A Flow Prediction Method of Centrifugal Pump Based on Power and Pressure Difference

A technology for flow prediction and centrifugal pumps, applied in pump control, non-variable pumps, special data processing applications, etc., can solve problems such as high cost, poor integration, and inability to effectively predict flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0101] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

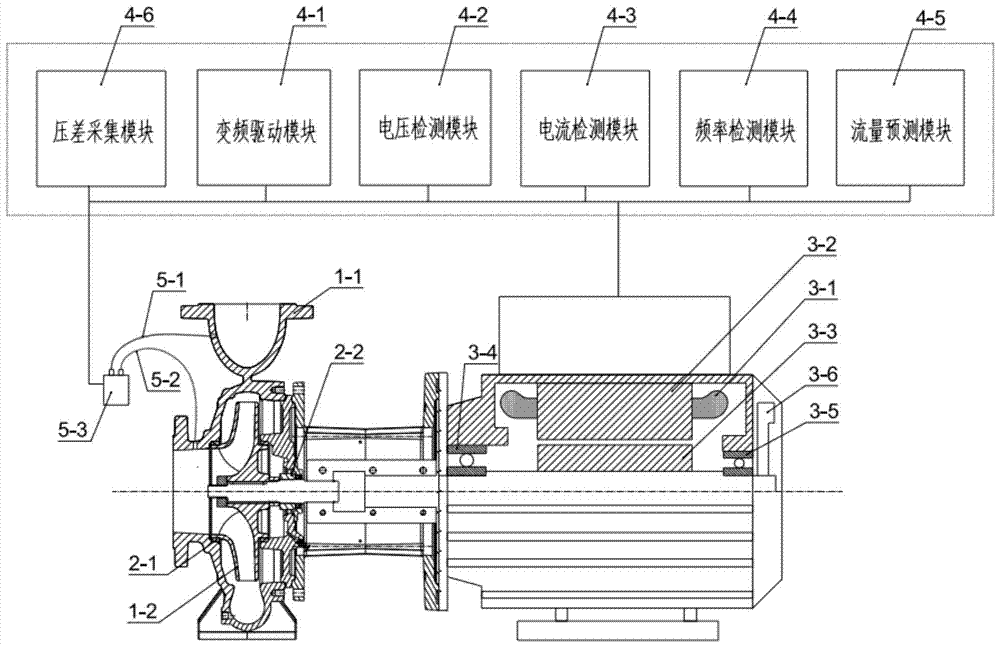

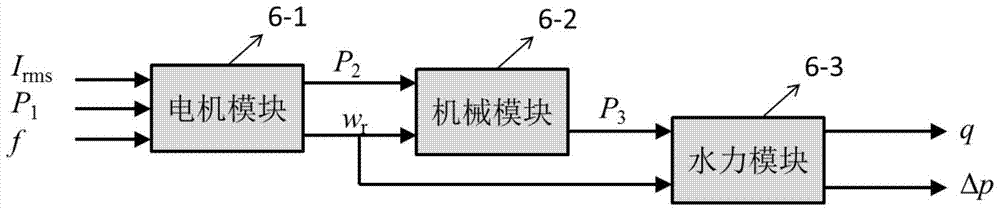

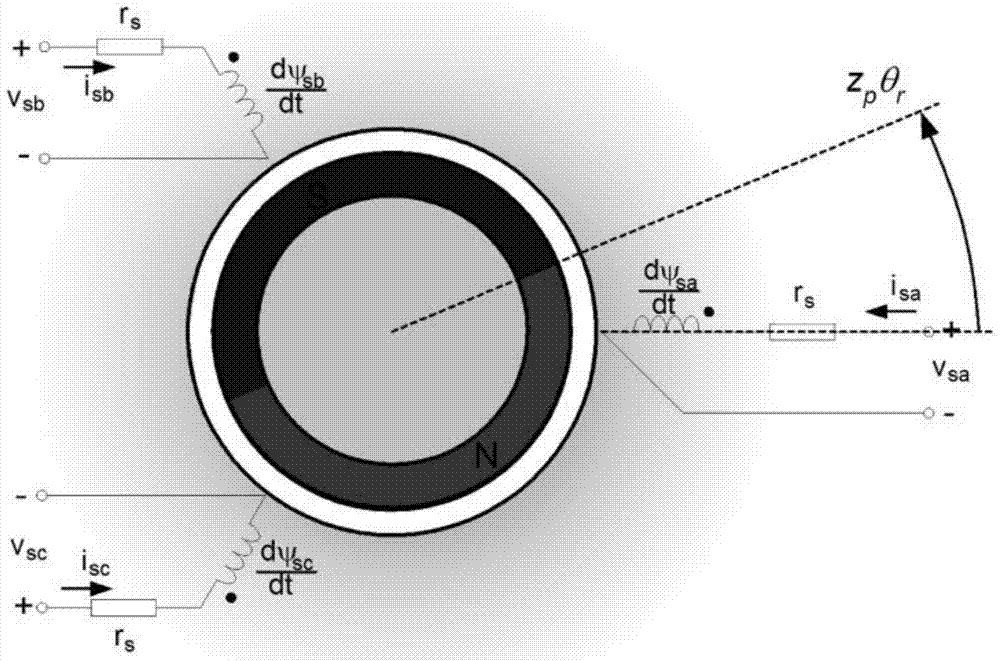

[0102] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 , a specific implementation of a centrifugal pump flow prediction method based on power and pressure difference is shown below:

[0103] Step 1. Construct a centrifugal pump flow prediction model based on the 'Gray-box modeling' theory;

[0104] According to the principle of energy conservation, the centrifugal pump is divided into three modules as a whole, namely, the motor module (6-1), the mechanical module (6-2) and the hydraulic module (6-3), and each module has corresponding input parameters And the output parameters and the internal energy transfer model, here it is defined as a 'gray box' module, in which the motor module is the first 'gray box'; the mechanical module is the second 'gray box'; the hydraulic module is the third 'gray box' '; For the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com