Carbon brush

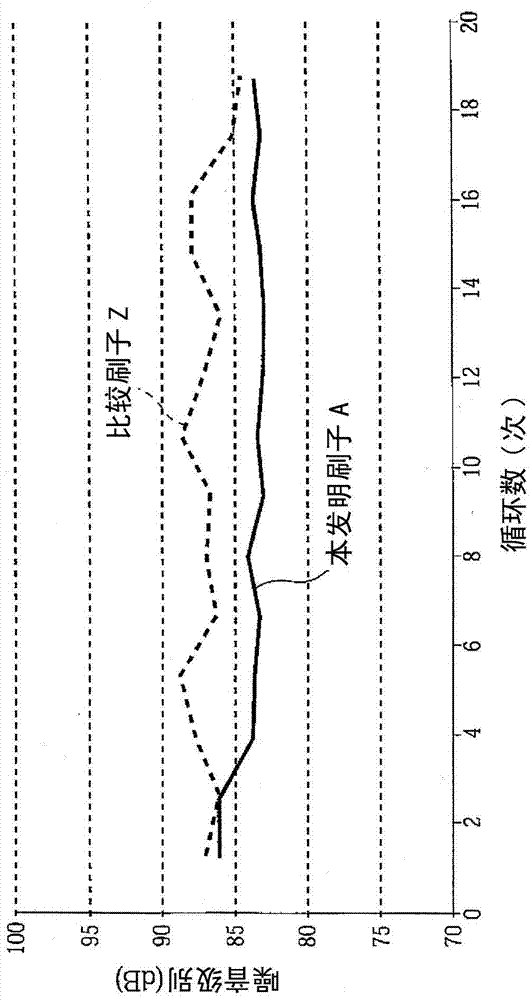

A carbon brush and carbon block technology, applied in current collectors, electrical components, electromechanical devices, etc., can solve the problems of louder sliding sound and increase in brush temperature, and achieve the effect of suppressing the increase of sliding sound and temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] Hereinafter, the present invention will be specifically described based on examples, but the carbon brush of the present invention is not limited by the contents of the following examples.

[0043] [Example]

[0044] The carbon brush of the present invention is produced as follows.

[0045] First, pitch was added as a binder in a ratio of 50% by weight to the total amount of graphite powder. Next, kneading was carried out at a high temperature higher than the melting point of the pitch, and then cooled and pulverized to obtain a molding material which passed through a 40-mesh sieve. Next, the molding raw material is press-molded using a pressing device, and fired at a high temperature in a non-oxidizing atmosphere to carbonize the binder to obtain a carbon block base material. Subsequently, the carbon block base material is cut to a specified size, and then lead wires are mounted on the carbon block base material.

[0046] Then, the suspension was impregnated into po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com