Wall-mounted oxygen inhalator

A wall-plug-in, inhaler technology, applied in the field of medical devices, can solve the problems of difficulty in guaranteeing the quality of the humidification bottle, easy bottle explosion, etc., and achieve the effects of easy processing and assembly, improving safety, and ensuring wall thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

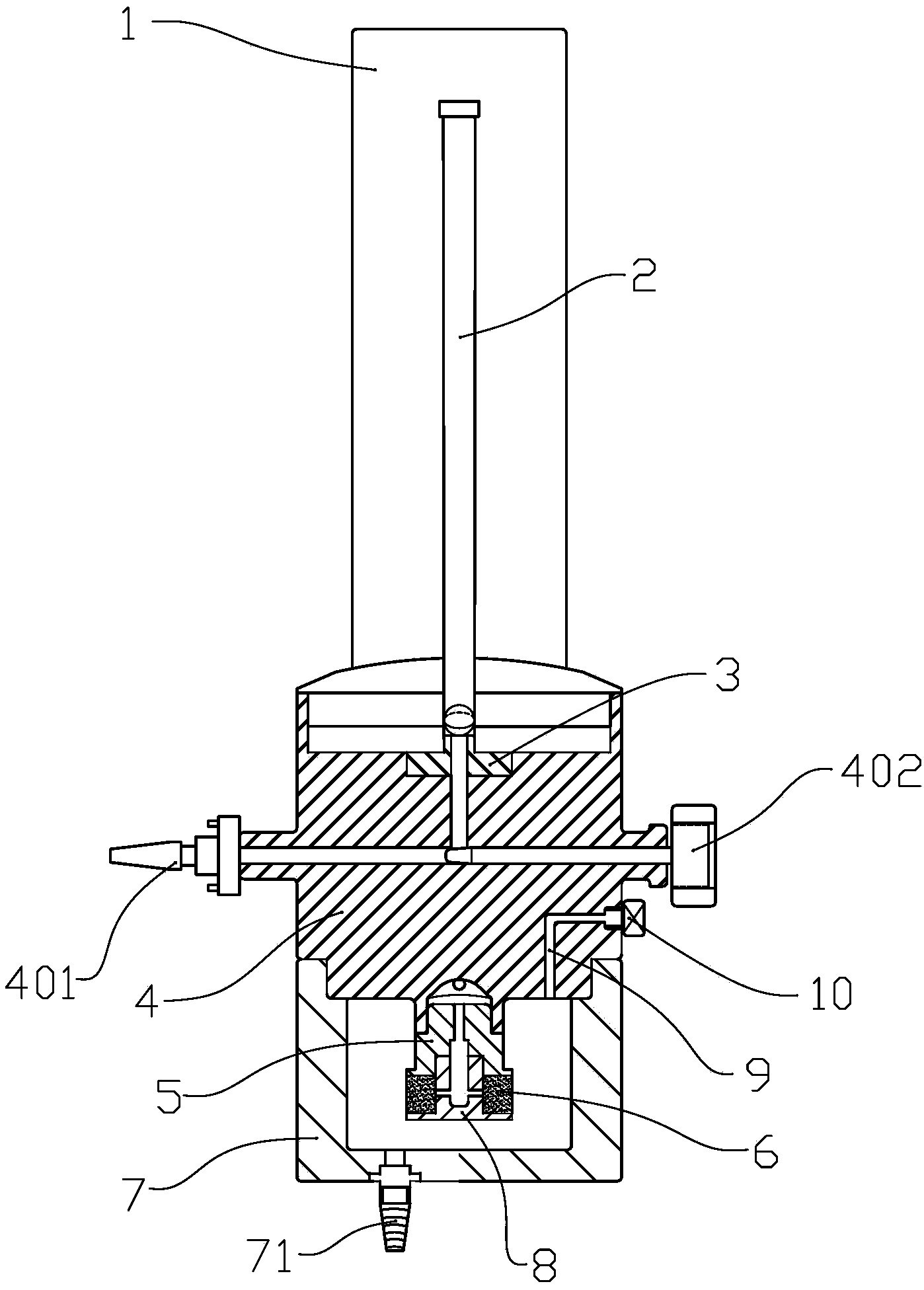

[0037] Such as Figure 1 to Figure 7 as shown,

[0038] A wall-plug type oxygen inhaler, comprising a cup 1, a buoy flow meter 2, an upper connecting piece 3, a connector 4, and a filter collar 6.

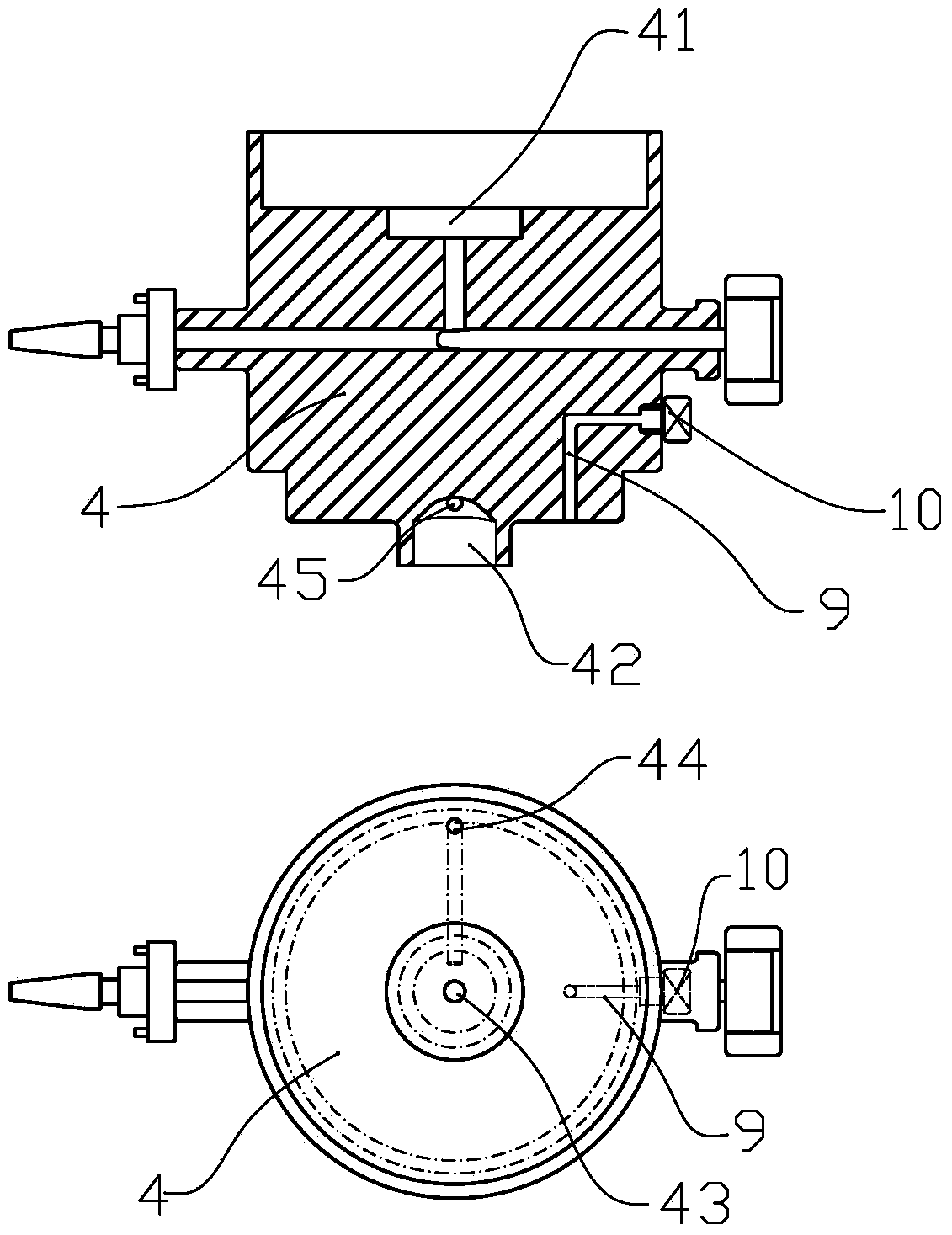

[0039] The breast cup 1 is connected in the internal thread groove at the upper end of the connector 4 . The buoy flowmeter 2 is matched with the connector 4 through the upper connecting piece 3 and placed in the cup 1 . The upper connector 3 is provided with an axial through hole, which is installed in the slot hole 41 at the bottom of the internal thread groove at the upper end of the connector 4 . An oxygen supply chamber interface 401 and a corresponding flow adjustment knob 402 are provided on the side wall of the connector 4 . An oxygen inlet channel 43 is provided along the axial direction of the connector 4, and the oxygen supply chamber interface 401, the oxygen inlet channel 43, the axial through hole of the upper connector 3, and the buoy flowmeter 2 are sequentially ...

Embodiment approach 2

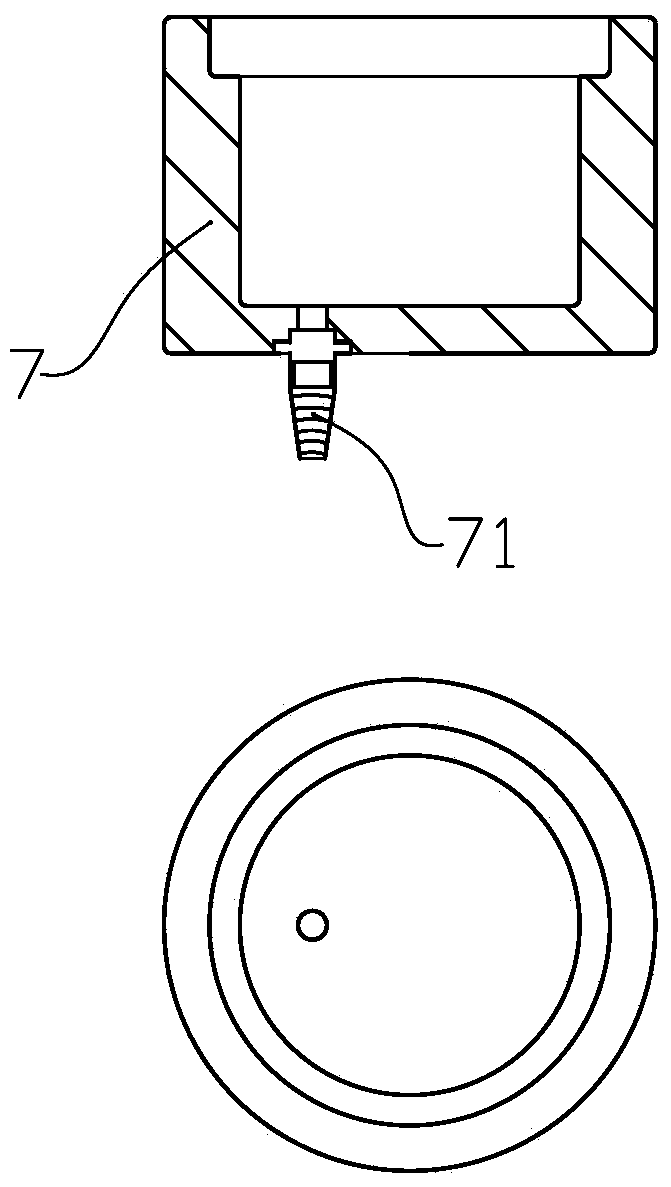

[0051] The difference from Embodiment 1 is that the upper end of the end cap 7 is provided with a stepped hole, wherein the uppermost section of the stepped hole is a light hole, and the bottom of this section is a threaded hole, and the diameter of the light hole part is larger than that of the threaded hole. aperture. The end cap 7 is matched with the connector 4 through the threaded hole. An axially extending groove (which may be a cylindrical groove) is arranged on the lower end surface of the connector 4 , and the inlet of the pressure relief channel 9 is arranged on the bottom surface of the groove. The oxygen tube interface 71 is arranged at the upper light hole portion of the end cover 7 . The upper part of the stepped hole at the upper end of the end cap 7 is a light hole and the oxygen tube interface 71 is correspondingly arranged in this part, so as not to adversely affect the threaded relationship between the end cap 7 and the connector 4 and the sealing performan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com