Turbo type reinforcing steel bar tail compressing machine

A tail presser and turbine-type technology, which is applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of irregular shape of the tail end of steel, failure to meet the standard, and affect the pass rate, etc., to achieve simple structure and easy The effect of processing and manufacturing and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

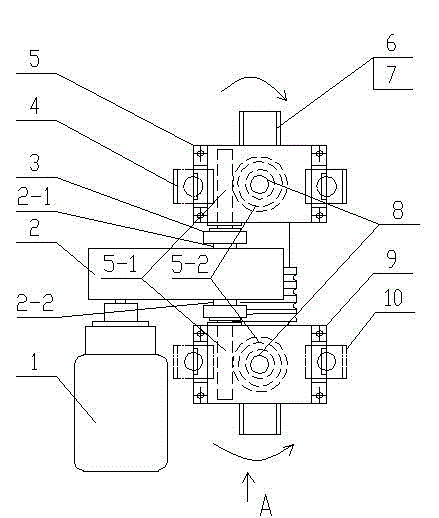

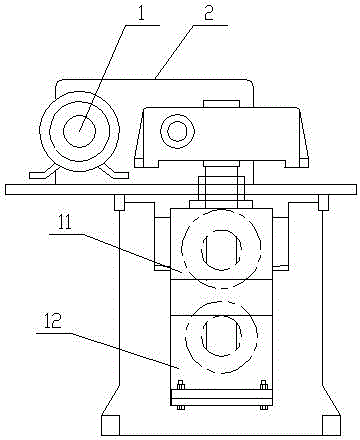

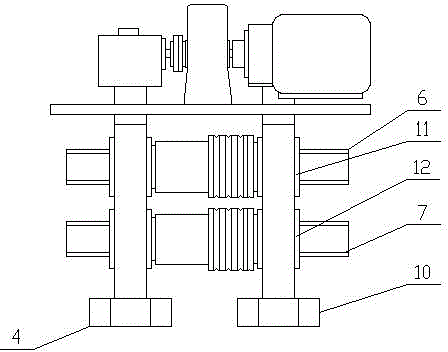

[0019] like Figure 1-3 As shown, the present embodiment provides a turbine-type steel bar tail pressing machine, which includes a drive motor 1, a double output shaft reducer 2 connected to the drive motor 1, and the left and right sides of the double output shaft reducer 2 are respectively connected by a coupling 3. Left turbine box 5 and right turbine box 9, left turbine box) and right turbine box 9 lower ends are provided with left frame 4 and right frame 10 respectively, are provided with upper roll 6 and between left frame 4 and right frame 10 The lower roll 7; the upper bearing seat 11 is a sliding bearing seat that can move up and down in the vertical direction, and the lower bearing seat 12 is a fixed bearing seat fixed on the left frame 4 and the right frame 10; the left turbine box 5 and the right turbine box Case 9 all comprises worm screw 5-1 and turbine 5-2, and the turbine 5-2 of left turbine case 5 and right turbine case 9 turns oppositely, and the center of t...

Embodiment 2

[0022] This embodiment is optimized as follows on the basis of Embodiment 1. Specifically, the double output shaft speed reducer 2 includes the left output shaft 2-1 and the right output shaft 2-2, the left output shaft 2-1 and the The right output shaft 2-2 is collinear.

[0023] In this implementation, the left output shaft 2-1 and the right output shaft 2-2 are collinear, and the two output shafts are collinear to make the transmission stable, so that the heights of the left turbine box 5 and the right turbine box 9 are the same. This structure ensures that the subsequent left machine The design installation of frame 4 and right frame 10 is easier to realize that upper roller 6 is stable in the lifting process, guarantees work quality and efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com