Method of Improving Elongation of High Surface Grade IF Steel

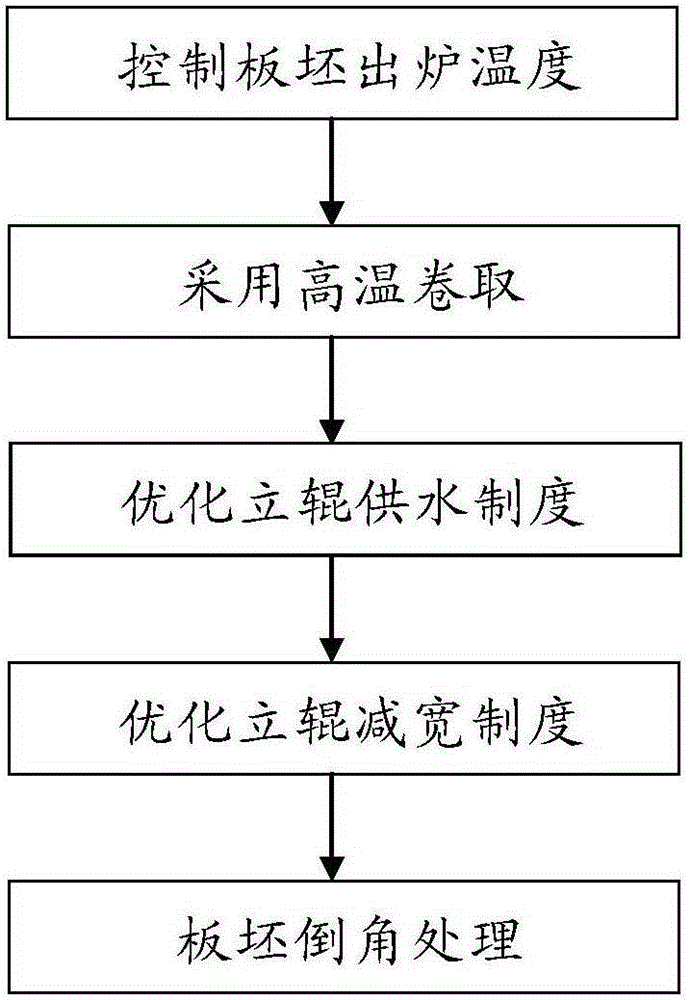

A technology with elongation and high surface, which is applied in the field of elongation of grade IF steel, can solve the problems of edge warping, rough edge and thin lines on the surface of finished products, and achieve the effect of suppressing edge warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] High surface grade IF steel is produced through continuous casting of molten steel to obtain slab, heating slab, hot rolling vertical roll widening, hot rolling flat roll thinning and high temperature coiling. In the case of other process conditions being the same, two different slab exit temperatures were used to compare the influence of the exit temperature on the mechanical properties such as elongation of the finished product. The two exit temperatures were 1270°C and 1210°C. The mechanical properties such as elongation of the finished products produced under the two furnace temperatures are shown in Table 1.

[0036] Table 1

[0037]

[0038] It can be seen from the data in Table 1 that using a lower slab temperature can effectively improve the elongation and r value of the finished product. Compared with the high temperature furnace at 1270 °C, the low temperature furnace at 1210 °C can significantly increase the elongation and r value of the finished product,...

Embodiment 2

[0040]The other process steps and process conditions are the same. In the case of 1210°C low temperature, this example compares two coiling temperatures with different heights to illustrate the influence of coiling temperature on the mechanical properties such as elongation of the finished product. The two coil temperatures were 650°C and 750°C. The mechanical properties such as elongation of the finished products produced under the two coiling temperatures are shown in Table 2.

[0041] Table 2

[0042]

[0043] It can be seen from the data in Table 2 that increasing the coiling temperature can effectively improve the elongation and r value of the finished product. In the case of 1210°C low temperature coiling, the elongation can be increased from 46.9% at 650°C coiling to 48.9%, the r value is increased from 2.88 to 3.03, and the yield strength and tensile strength are slightly higher than 750°C. There is a decline, but it will not affect the performance of the finished...

Embodiment 3

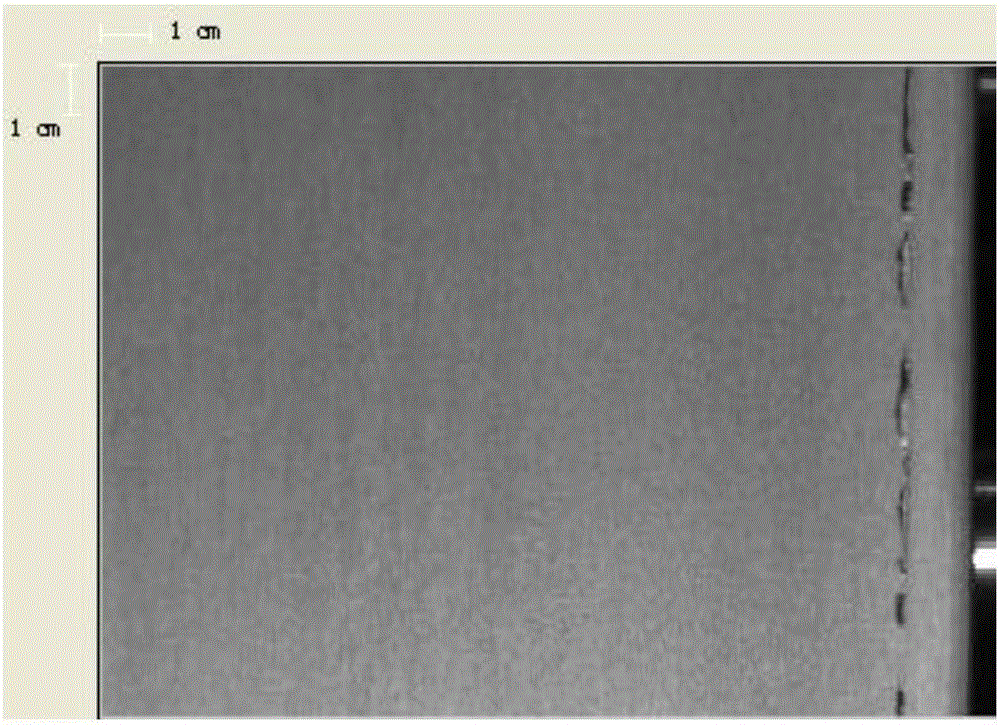

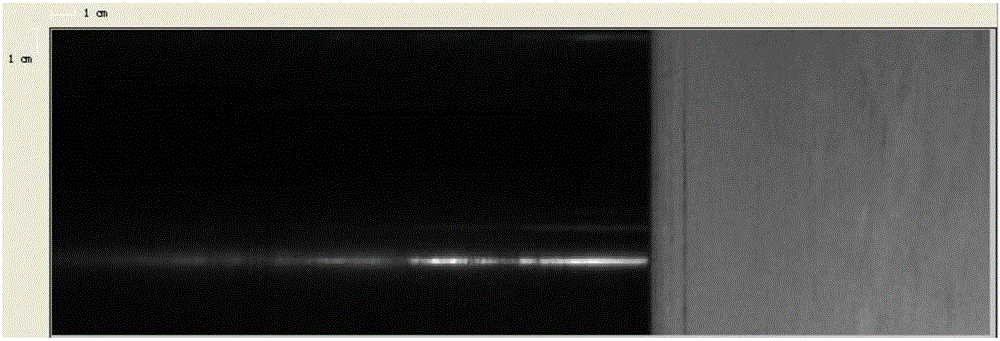

[0045] see figure 2 , lowering the furnace temperature will increase the temperature drop of the edge while increasing the elongation of the finished product, which will easily lead to the occurrence of defects in the hot curling edge. In order to improve the edge quality of the slab when the slab is released from the furnace at low temperature, the water supply system of the vertical roll is optimized under the condition that the process steps and other process parameters remain unchanged, and the vertical roll water supply mode of the normal water supply in the rolling gap and the reduced water supply mode during rolling are adopted. system, the flow of cooling water in the vertical rolling process will be changed from the previous 60m 3 / h reduced to 25~30m 3 / h, while the cooling water flow in the rolling gap is maintained at 60m 3 / h is constant, and the final surface morphology of the hot coil is as follows image 3 shown. From figure 2 and image 3 It can be see...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com