Tool for mounting tooth holder of end effector for mining equipment

A technology for mining equipment and actuators, which is applied in the field of tooling for the installation of tooth seats of the terminal actuators of mining equipment, which can solve the problems of difficulty in meeting the requirements of small and medium-sized enterprises or product diversity, high cost of testing tooling, and high labor intensity of workers. Achieve the effects of easy promotion and use, convenient welding and maintenance, and improved working strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

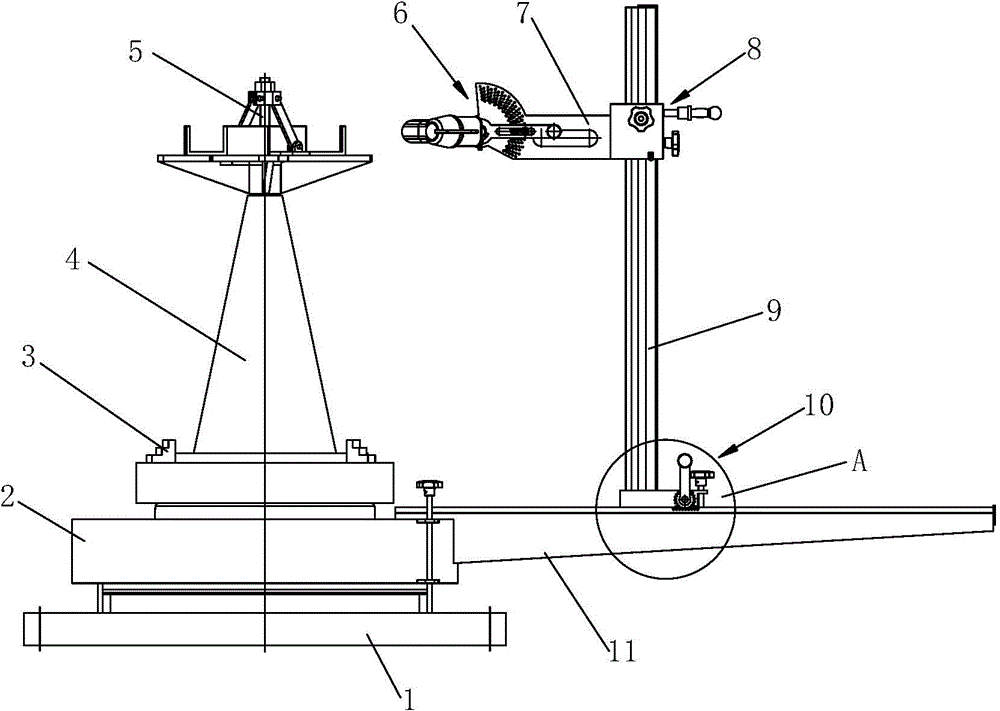

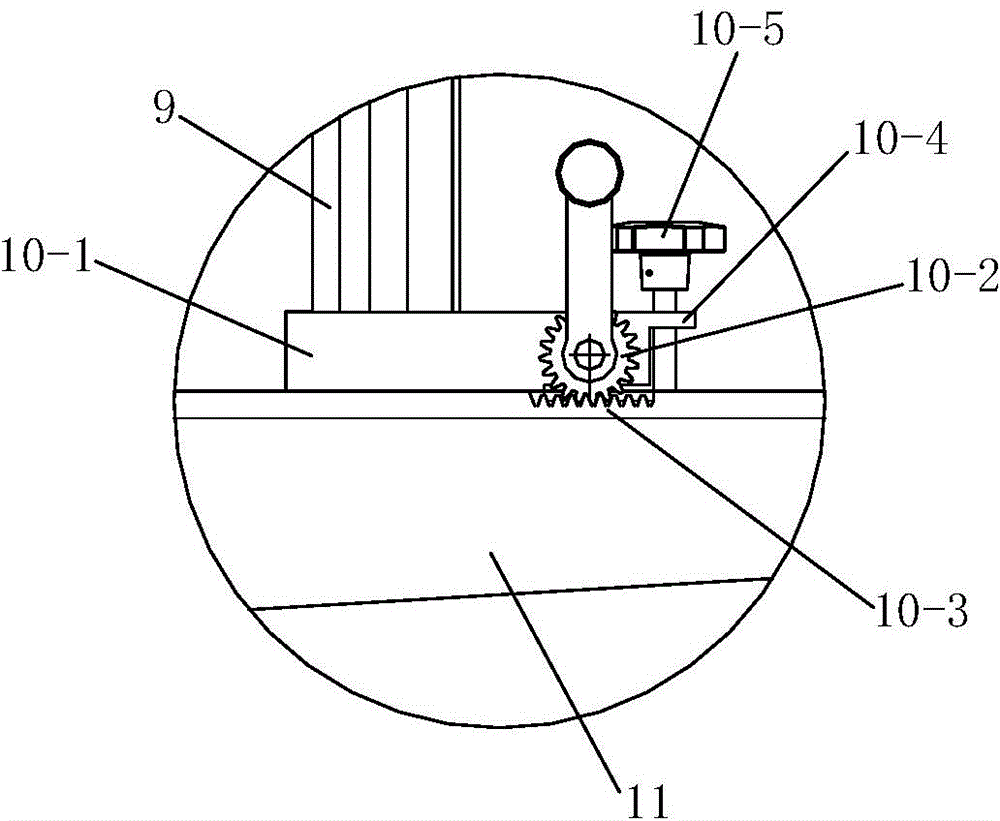

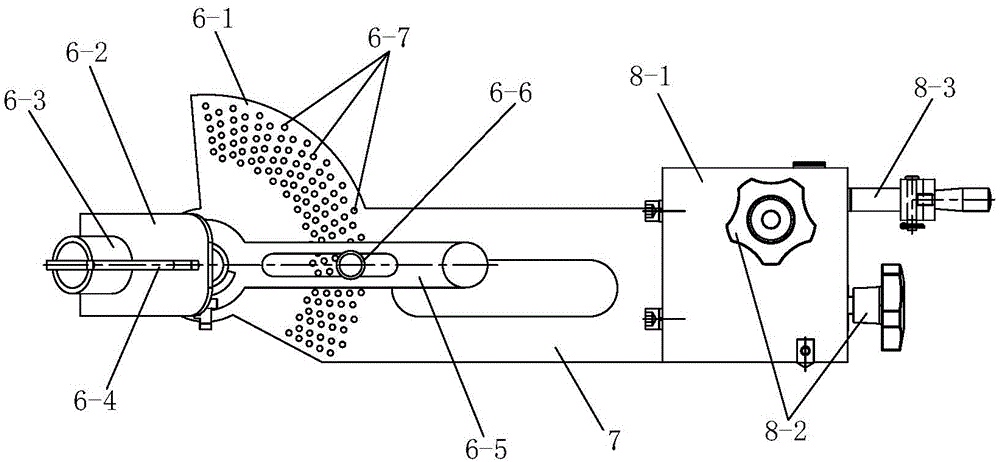

[0037] Such as figure 1 The tooling for installing the gear seat of the mining equipment terminal actuator shown includes a base 1, a supporting frame 4 arranged on the base 1, and a positioning card arranged on the supporting frame 4 and used to clamp the mining equipment terminal actuator Disk 5, a turntable 2 is rotatably mounted on the base 1 and located below the support frame 4. The side of the turntable 2 is connected with a revolving arm 11, the revolving arm 11 is provided with a column 9, and the column 9 is provided There is a cross arm 7, and a tooth seat positioning jig 6 for clamping the tooth seat is installed on the cross arm 7, and the lower end of the column 9 is provided for driving the column 9 to approach the support frame 4 or away from the support frame 4 along the revolving arm 11 The moving mechanism 10 of the cross arm 7 is provided with a lifting mechanism 8 for driving the cross arm 7 to rise and fall along the column 9.

[0038] Combine image 3 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com