Curling wire packing machine

A wire winding and wrapping technology, which is applied in the direction of presses, metal processing machinery parts, turning equipment, etc., can solve the problems of inconvenient remelting in furnaces, inconvenient waste recycling and transportation, aluminum wire winding machine tool spindles, etc., to save production The effect of saving space, saving manpower and reducing manpower input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

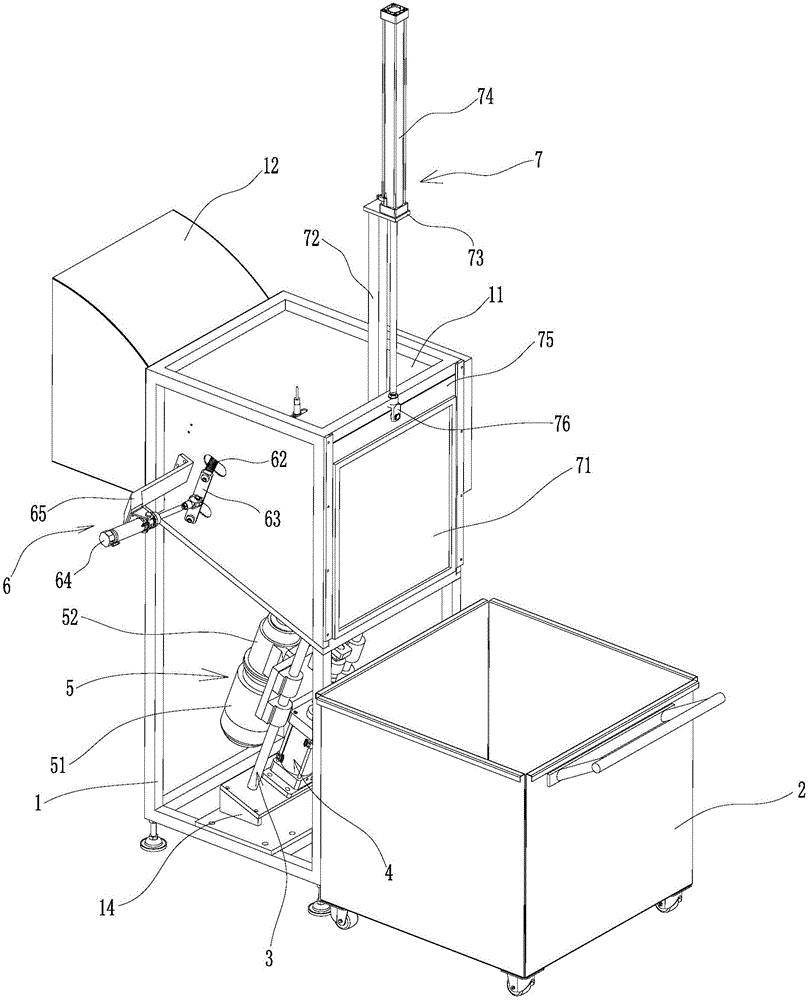

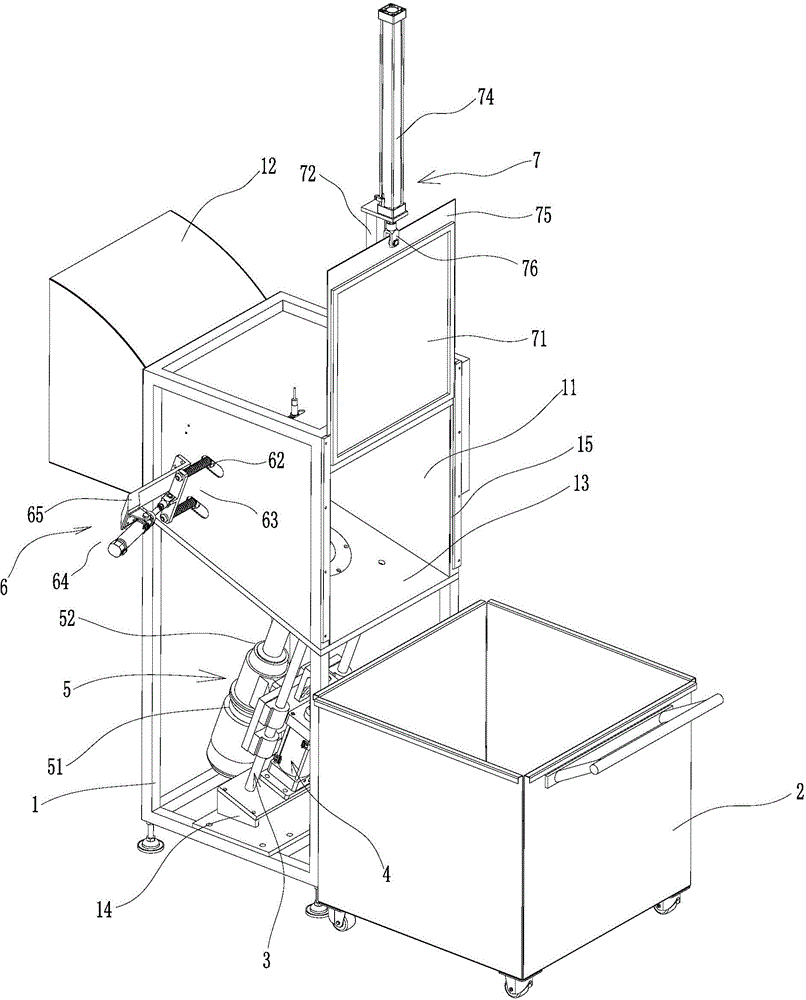

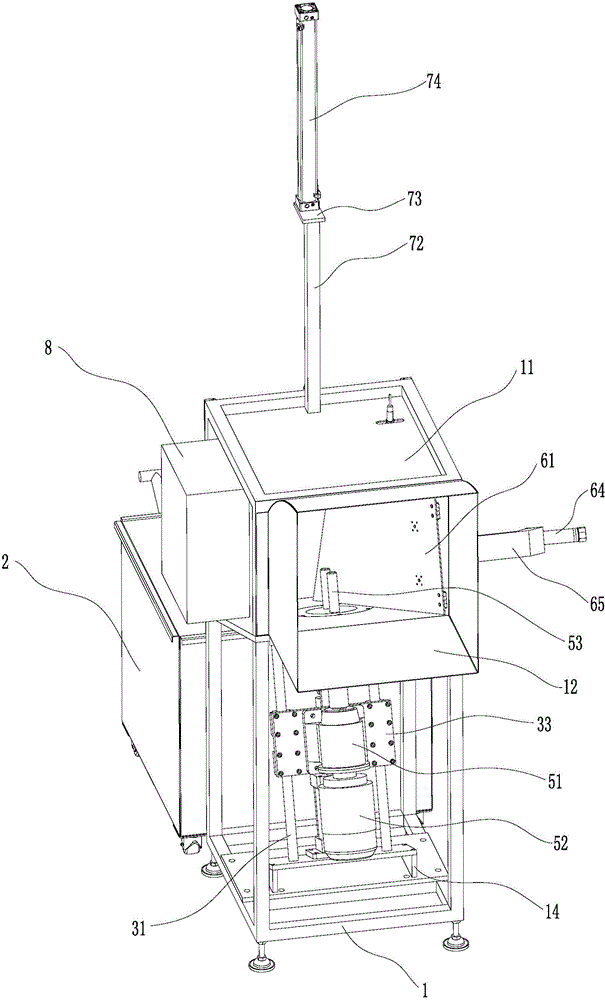

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0031] As shown in the figure, the upper part of the frame 1 forms an aluminum wire recycling chamber 11, and the front end of the aluminum wire recycling chamber 11 is provided with an aluminum wire guide part 12 communicating with it. The bottom plate of the aluminum wire recycling chamber 11 is a coil Wire bottom plate 13, this winding wire bottom plate 13 is the slant plate that utilizes dead weight to slide out of the aluminum wire recycling cavity for the convenience of aluminum wire coil. The front end of the aluminum wire guide part 12 and the aluminum wire recovery chamber 11 is detachably connected. The aluminum wire guiding part 12 is in the shape of a square tube, with openings at its front and rear ends, the opening at the front end is larger than the opening at the rear end, and the top is in the shape of an arc protruding outward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com