Closed-loop control method for electrospining direct writing technology

A closed-loop control and electrospinning technology, which is applied in filament generation, textile and papermaking, filament/thread forming, etc., can solve the problems of difficult closed-loop control of electrospinning direct writing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

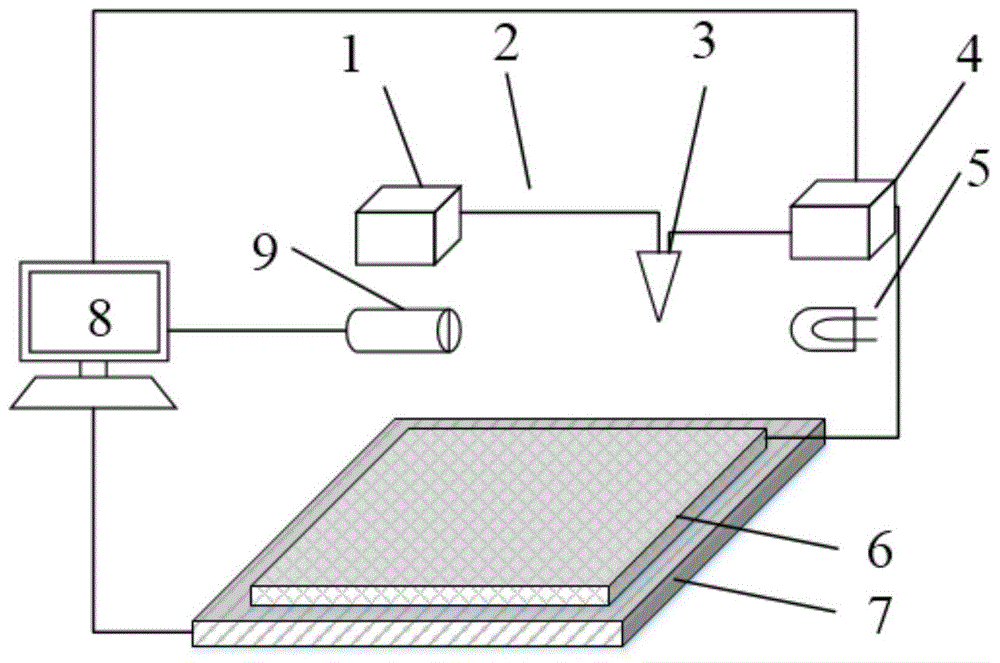

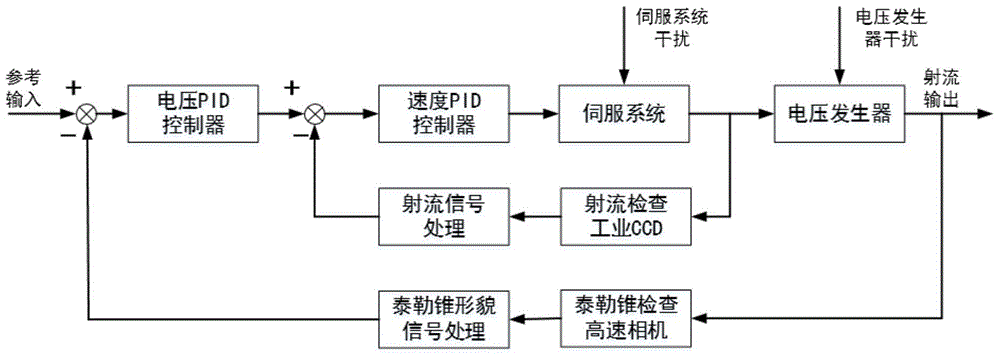

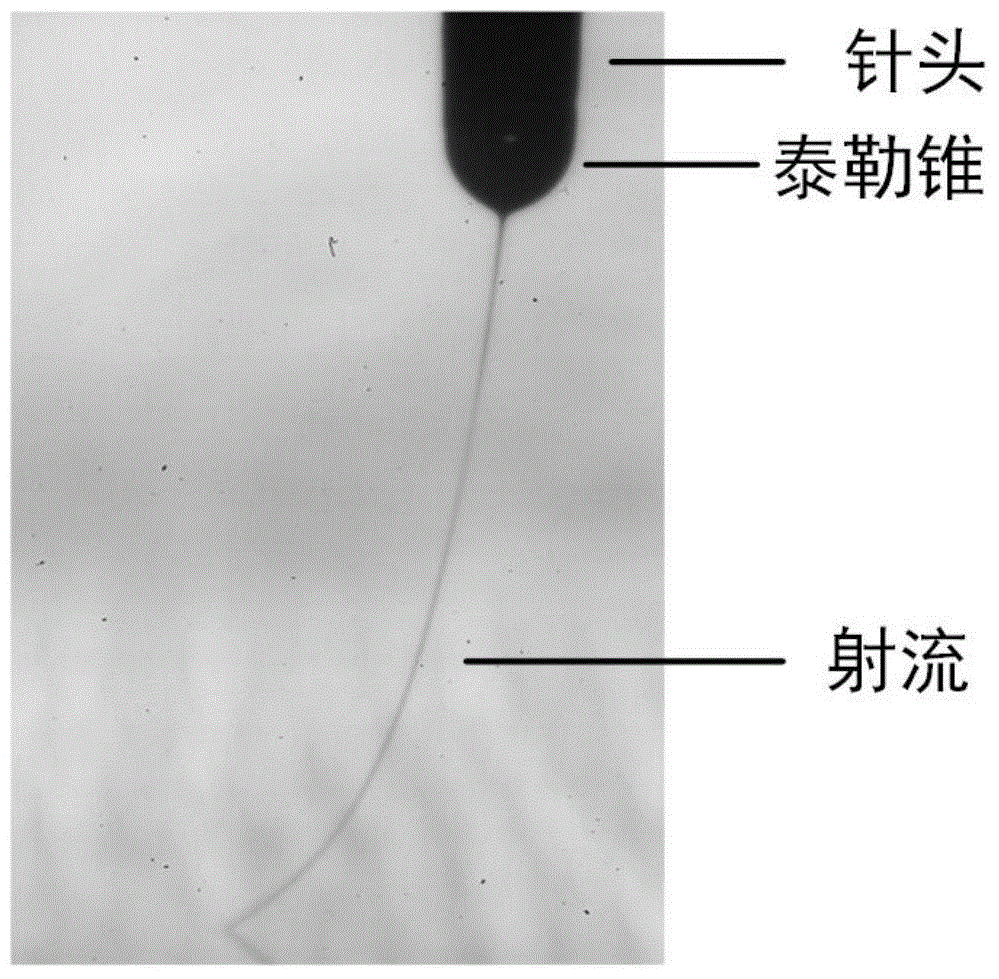

[0029] Such as figure 1As shown, the closed-loop control device of the electrospinning direct writing process includes: a flow pump 1, a catheter 2, a metal needle 3, a high-voltage generator 4, a light source 5, a collecting plate 6, a motion platform 7, a control computer 8, and a high-speed camera 9. Among them, the flow pump 1 is equipped with a syringe, and is connected to the metal needle 3 through the conduit 2, so that the printing liquid can be supplied according to the set flow rate; the positive pole of the high-voltage generator 4 is connected to the metal needle 3, and the negative pole is connected to the collecting plate 6, so that an electric field is generated between the two poles to cause jetting. On the other hand, the control cable is connected to the control computer 8 to control the voltage loading; The motion of the motion platform 7 is controlled; the light source 5 is arranged on one side of the nozzle, and the high-speed camera 9 is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com