Organosilicone modified epoxy resin and preparation method thereof as well as mica capacitor

A technology of epoxy resin and silicone, applied in the direction of fixed capacitor dielectric, fixed capacitor parts, etc., can solve the problem of restricting spaceflight and achieve the effect of improving the working height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

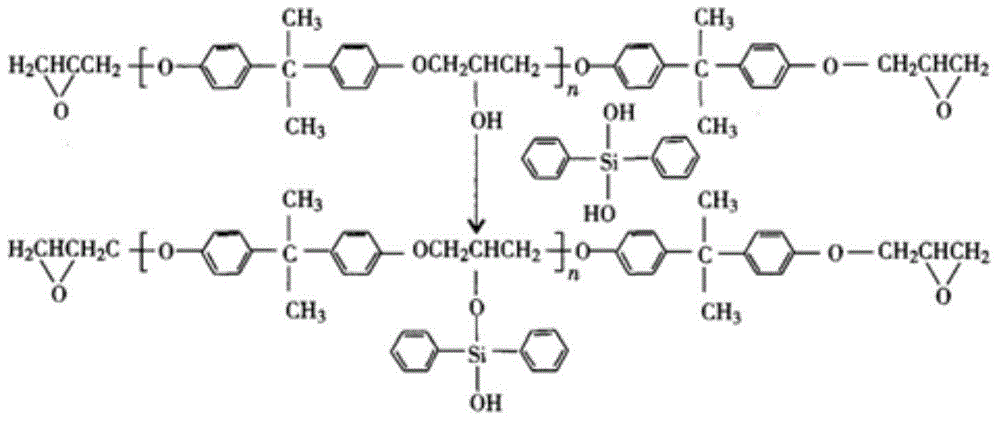

Method used

Image

Examples

Embodiment 1

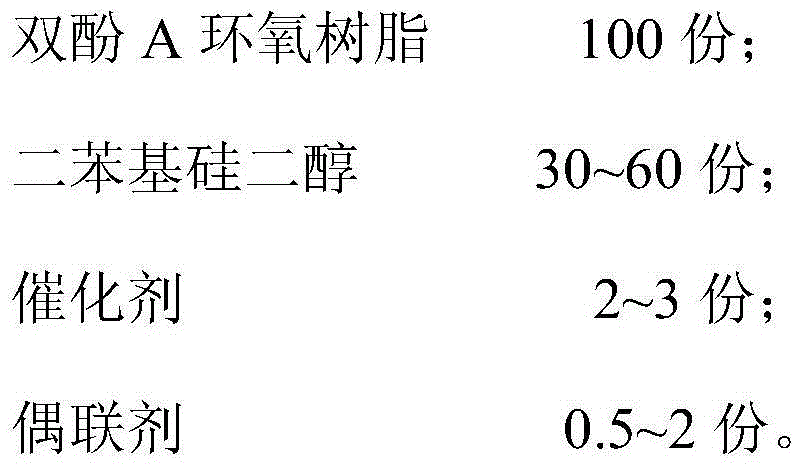

[0023] Embodiment 1: The organosilicon-modified epoxy resin of this implementation, by mass parts, comprises the following components:

[0024]

[0025] A method for preparing the above-mentioned organosilicon-modified epoxy resin, comprising the following steps:

[0026] In terms of parts by mass, add 100 parts of bisphenol A epoxy resin, 2 parts of dibutyltin dilaurate and 0.5 part of KH550 into the reaction vessel, heat up to 110°C, and drop 30 parts of diphenyl Silanediol, and stirred and reacted for 5 hours in a constant temperature heating device to obtain a light yellow translucent liquid, that is, a silicone-modified epoxy resin.

Embodiment 2

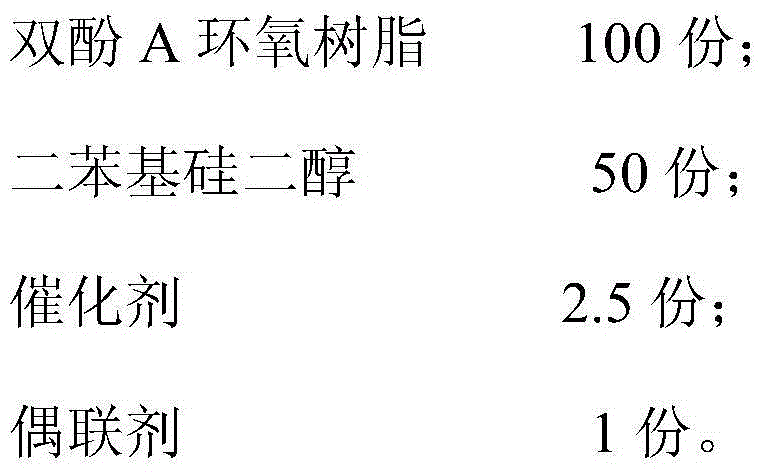

[0027] Embodiment 2: The organosilicon-modified epoxy resin of this implementation comprises the following components in parts by mass:

[0028]

[0029] A method for preparing the above-mentioned organosilicon-modified epoxy resin, comprising the following steps:

[0030] In parts by mass, add 100 parts of bisphenol A epoxy resin, 2.5 parts of dibutyltin dilaurate and 1 part of KH550 into the reaction vessel, heat up to 120°C, and drop 40 parts of diphenyl silicon within 1 hour diol, and stirred and reacted in a constant temperature heating device for 6 hours to obtain a light yellow translucent liquid, that is, a silicone-modified epoxy resin.

Embodiment 3

[0031] Embodiment 3: The organosilicon-modified epoxy resin of this implementation, by mass parts, comprises the following components:

[0032]

[0033] A method for preparing the above-mentioned organosilicon-modified epoxy resin, comprising the following steps:

[0034] In terms of parts by mass, add 100 parts of bisphenol A epoxy resin, 3 parts of dibutyltin dilaurate and 2 parts of KH550 into the reaction vessel, heat up to 130°C, and drop 60 parts of diphenyl silicon within 2 hours diol, and stirred and reacted in a constant temperature heating device for 7 hours to obtain a light yellow translucent liquid, that is, a silicone-modified epoxy resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com