Preparation method of blowing promoter using urea as basal body

A foaming aid and foaming agent technology are applied in the field of preparation of foaming aids, which can solve the problems of high decomposition speed, heat release, and high decomposition temperature, and achieve the advantages of recycling, improving safety performance and high safety performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method of this foaming aid with urea as the matrix according to the present invention, the foaming aid is a complex of polyoxyethylene PEO and urea, and the specific steps are as follows:

[0018] (1), dissolving urea in water, stirring to dissolve urea, and preparing an aqueous urea solution with a mass fraction of 1% to 10%;

[0019] (2) Add polyoxyethylene PEO to the urea aqueous solution at the ratio of 1 mole of monomeric bonds to 2 moles of urea in polyoxyethylene PEO, heat and stir, set the temperature at 20-70°C, and stir for 0.5 -2h, the solution is a colorless transparent liquid;

[0020] (3) After the stirring is stopped, the above liquid is distilled under reduced pressure, and the temperature is controlled at 40-60°C. When the solution is distilled to a viscous state where solid and liquid coexist, stop the distillation, weigh the mass of the substance, and then carry out a vacuum drying oven. Drying, the temperature is 50°C, the vacuum deg...

Embodiment 1

[0027] First, add 0.3g of urea into 15ml of water, stir to dissolve the urea completely, then add 0.11g of PEO with a relative molecular weight of 3.5 million into the aqueous urea solution, and stir in a water bath at 40°C for 2 hours to form a transparent solution with a certain viscosity. Then carry out vacuum distillation at 40°C. When the solution becomes semi-solid state, stop stirring and transfer to a vacuum drying oven for drying. After drying, it becomes a complex crystal.

Embodiment 2

[0029] First, add 60g of urea to 50ml of water, stir to dissolve the urea completely, then add 22g of PEO with a relative molecular weight of 3.5 million to the urea solution, and stir the two in a 50°C water bath for 0.5h to form a transparent solution with a certain viscosity . Then carry out vacuum distillation at 60°C. When the solution becomes a semi-solid state, stop stirring and transfer to a vacuum drying oven for drying. After drying, it becomes a complex crystal.

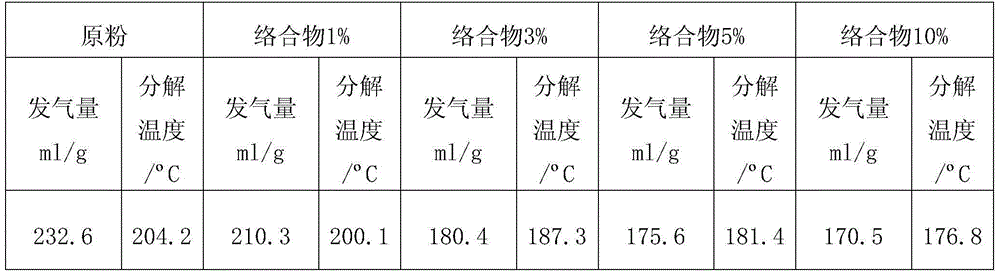

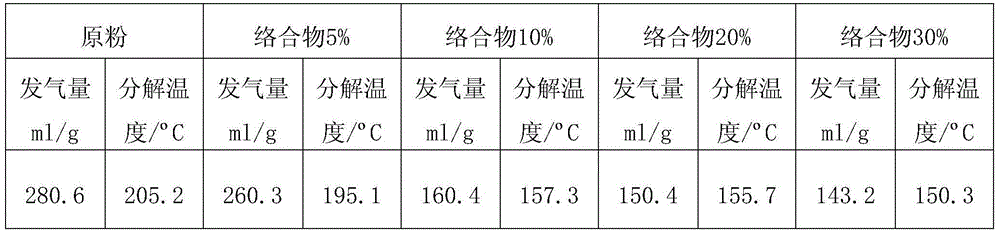

[0030] 2. Compounding of complex and ADC foaming agent

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com