Pavement roughness detection system and method

A detection system and flatness technology, applied in roads, roads, road repair, etc., can solve problems such as large shrinkage ratio of concrete, decreased road surface flatness, and inconvenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

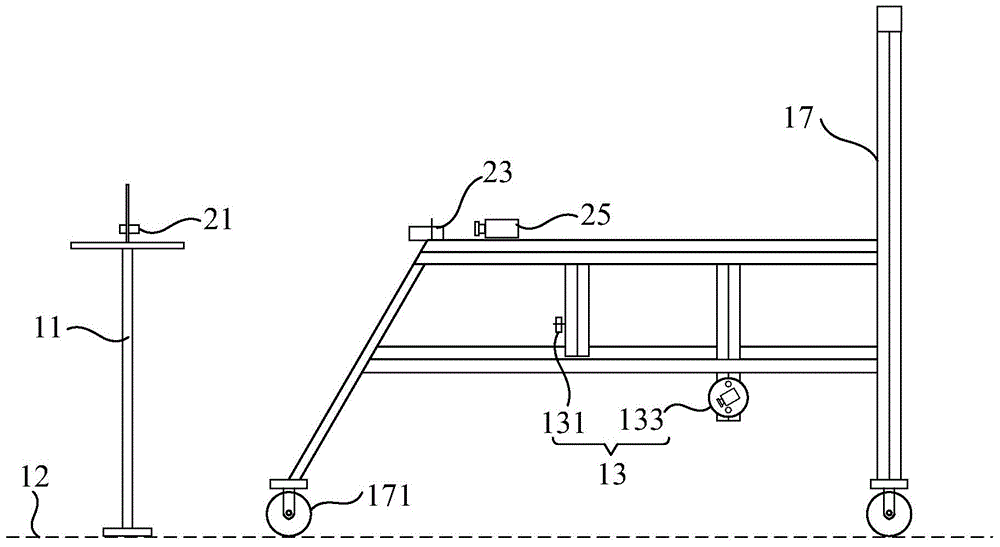

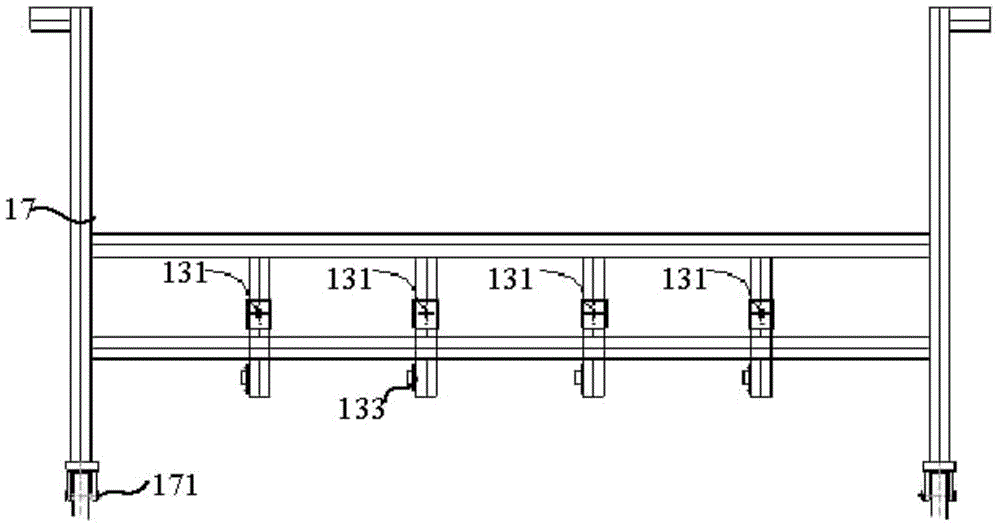

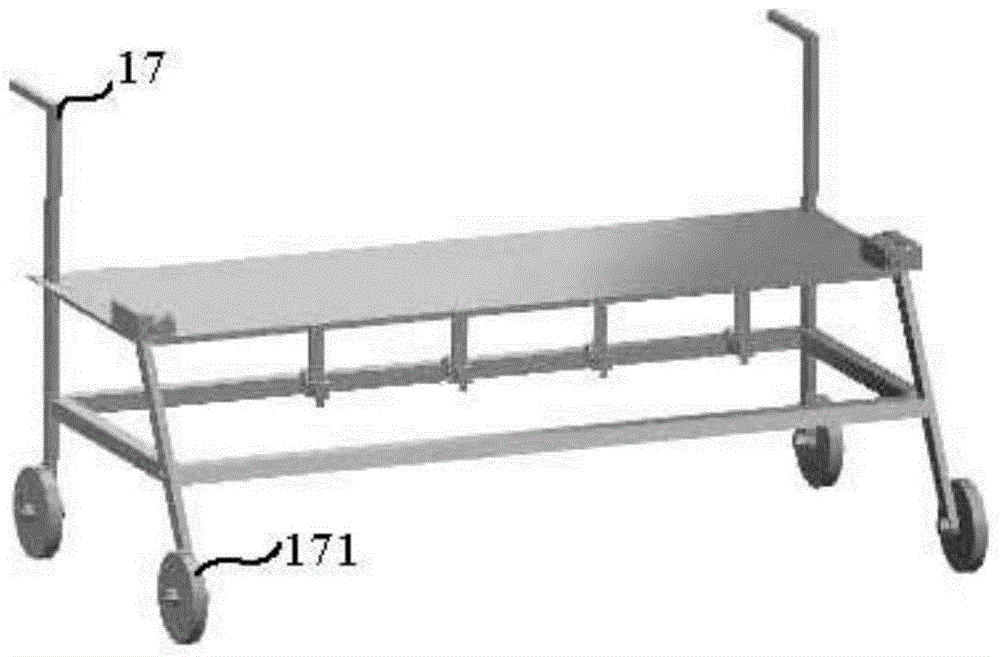

[0055] Figure 1a and Figure 1b It is a schematic structural diagram of the road surface smoothness detection system according to the first embodiment of the present invention, as shown in Figure 1a and Figure 1b As shown, the road surface smoothness detection system may mainly include:

[0056] At least one reference target 11 is arranged above the road surface 12 to be measured;

[0057] at least one linear structured light sensor 13, used for projecting linear structured light to the road surface 12 to be measured, and capturing a light bar image formed by the linear structured light on the road surface 12 to be measured;

[0058] A computing device (not shown in the figure), connected with the line structured light sensor 13 , converts the light bar image received from the line structured light sensor 13 into three-dimensional data, and analyzes the data according to the reference target 11 The three-dimensional data of the road surface to be measured is corrected, ...

Embodiment 2

[0065] Figure 4 It is a schematic structural diagram of the pavement flatness detection system according to the second embodiment of the present invention, Figure 4 shown with Figure 1a , Figure 1b , figure 2 , image 3 Components with the same label have the same meaning and will not be repeated here. like Figure 4 As shown in the figure, the main difference from the above-mentioned embodiment is that, in this road surface flatness detection system, a rangefinder 31 is set on the mobile measuring bridge 17, and a range finder 31 is set on the reference target 11 corresponding to the position of the rangefinder 31. the target board 33; the rangefinder 31 is used to project laser light to the target board 33 on the reference target 11, and receive the laser light returned from the target board 33 to measure the movement of the measurement bridge 17 and the The distance between the reference targets 11 is sent to the computing device so that the computing device can ...

Embodiment 3

[0071] Figure 5 It is a flow chart of the road surface smoothness detection method according to the third embodiment of the present invention, such as Figure 5As shown, the road surface smoothness detection method can use any structure of the road surface smoothness detection system in the above-mentioned embodiments to detect the smoothness of the road surface to be measured, and the method may specifically include:

[0072] Step 101, using the first CCD to capture the light strip image formed by the line structured light emitted by the line structured light sensor on the road surface to be measured;

[0073] Step 102, converting the light bar image into three-dimensional data of the road surface to be measured;

[0074] Step 103, correcting the three-dimensional data of the road surface to be measured according to the reference target;

[0075] Step 104: Determine the smoothness of the road surface to be measured according to the corrected three-dimensional data.

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com