One-piece type pipeless massage pump with intermediate water spraying in water-collection vortex flow

A one-piece, eddy current technology, applied to parts of pumping devices for elastic fluids, non-variable pumps, pumps, etc., can solve the problems of impeller loss, insufficient concentration of water outlet, insufficient water outlet force, etc., to reduce Loss, energy-saving massage, high water output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

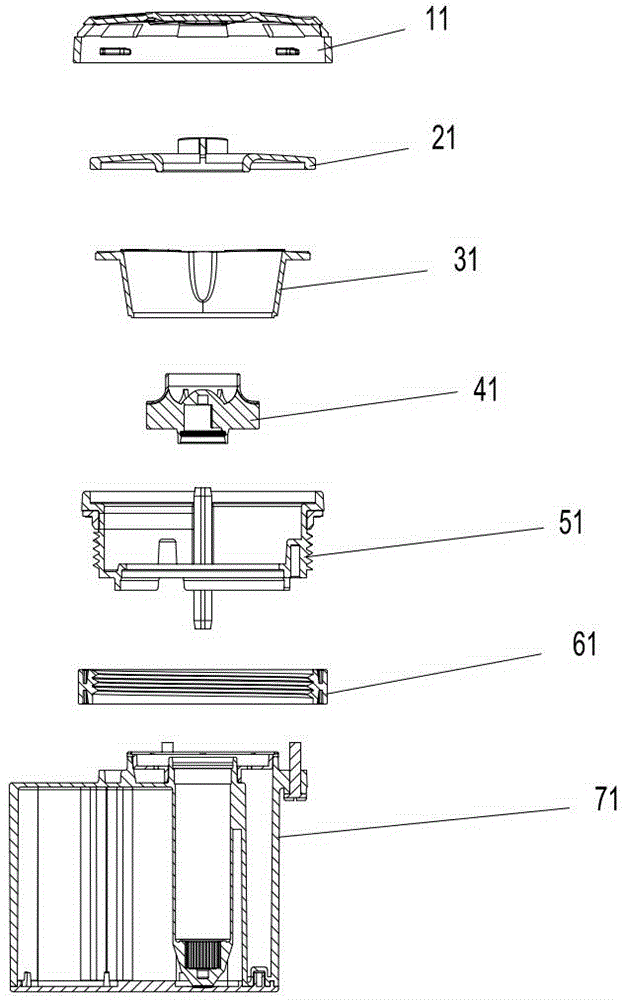

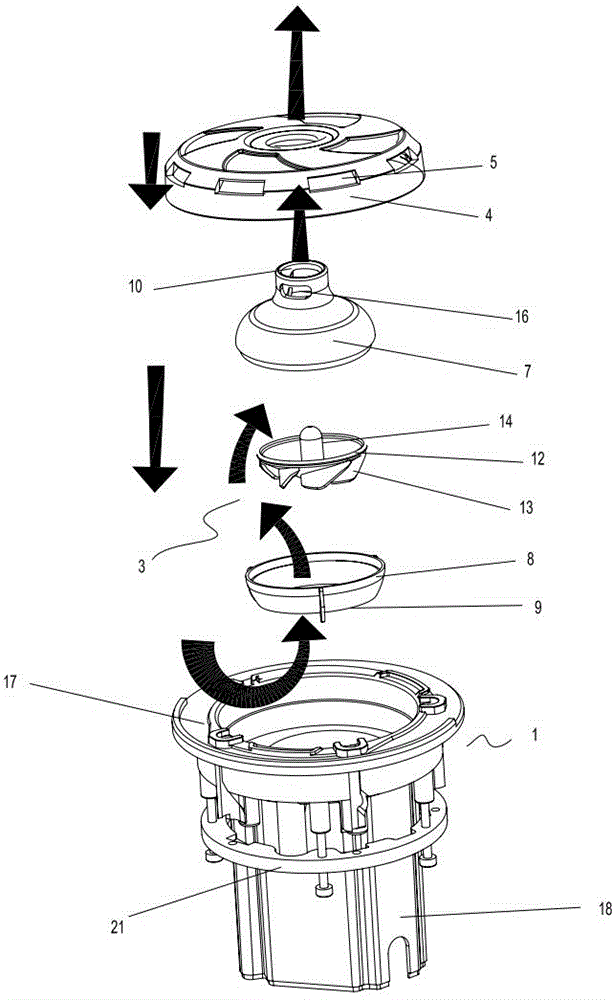

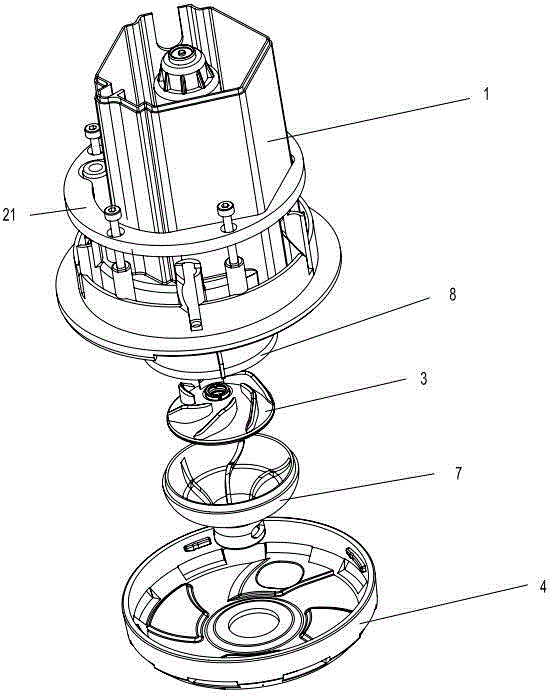

[0020] A kind of water-gathering vortex in the middle of the embodiment of the present invention sprays water one-piece pipeless massage pump, such as figure 2 , image 3 , Figure 4 and Figure 5As shown, it includes the pump body 1, the motor 2 installed in the pump body and at the bottom, the impeller 3 driven by the motor, the cover 4 and the water inlet 5 arranged on the cover, and the cavity formed by the pump body and the cover. The body is provided with a water guide assembly 6, the impeller is placed in the water outlet water guide chamber formed in the water guide assembly, the water inlet 9 of the water outlet water guide chamber is located at the bottom of the water guide assembly, and the top of the water guide assembly is provided with a water guide chamber water outlet 10 As outlet for ductless massage pumps. The pump body is a one-piece structure composed of a front pump body cavity 17 and a rear pump body cavity 18 and is integrally formed. The front end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com