Electromagnetic and intelligent coupler

A coupler, intelligent technology, applied in the direction of magnetic drive clutches, clutches, non-mechanical drive clutches, etc., can solve the problems of difficult processing technology, high manufacturing cost, easy deformation of the shell, etc., to achieve simple processing technology, avoid welding deformation, The effect of expanding the range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

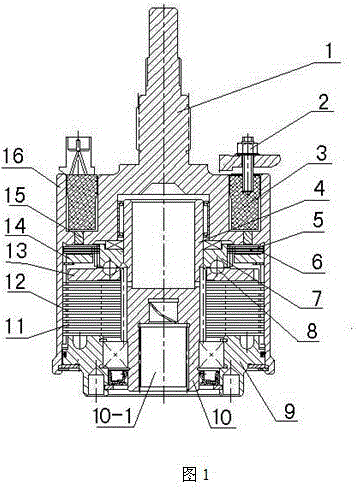

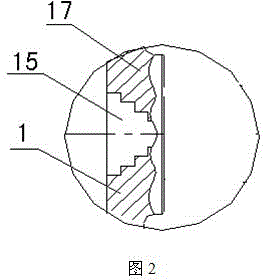

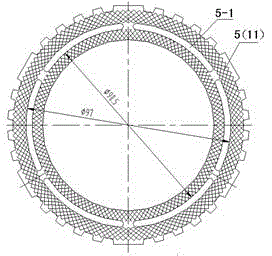

[0014] Depend on figure 1 As known, an electromagnetic smart coupler is a rotating body assembly, one end of which is a drive shaft 1, and the other end is an output shaft. The outside of the drive shaft 1 is provided with a housing 17 with an inner cavity, and the shoulder of the housing 17 is There is an annular groove 16 at the bottom, the electromagnetic coil 3 is arranged in the annular groove 16, and is in a clearance fit, and is locked in the annular groove 16 by the lock nut 2; the central axis 4 is located in the keyway of the rotating drive shaft 1, and the central axis 4 The upper part is provided with a thrust bearing drive plate 7 and a clutch pressure plate 13 with spline grooves in turn, and corresponding annular semicircular grooves are respectively provided on the opposite surfaces of the thrust bearing drive plate 7 and clutch pressure plate 13, and a group of Steel ball 8; the middle part of the inner cavity of the housing 17 and the lower end of the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com