Brake disc for car

A technology of brake discs and cars, applied in the direction of brake discs, etc., can solve problems such as danger and reduced life of brake discs, and achieve the effect of convenient operation and clear ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

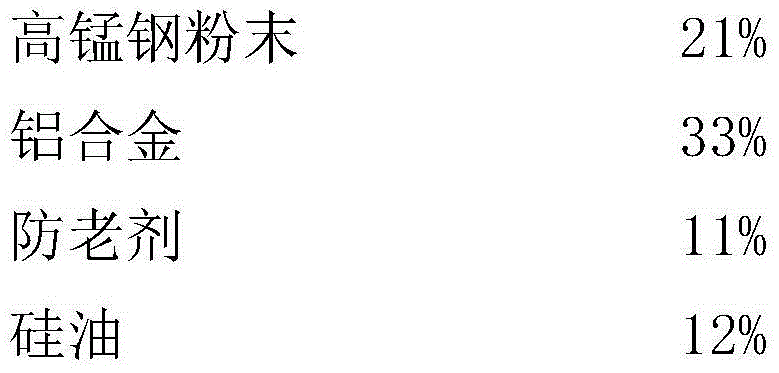

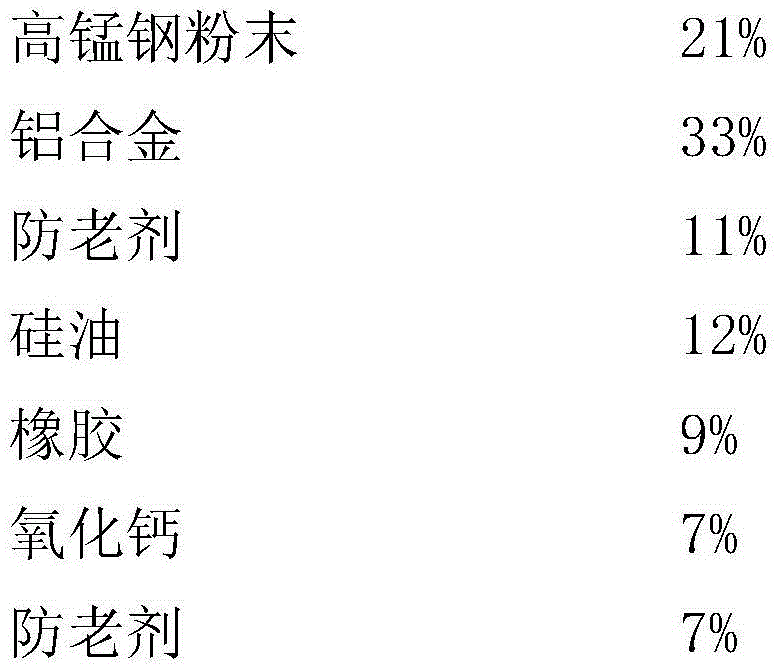

[0018] A brake disc for a car, characterized in that it comprises the following components,

[0019]

[0020] The present invention also provides a preparation method of a car brake disc, comprising the following steps,

[0021] Step 1. Melt the aluminum alloy in a melting furnace at 663-741°C for 27-41 minutes, then take out the liquid and place it in another constant temperature furnace at 555-637°C to keep the temperature;

[0022] Step 2, put the rubber into a pulverizer and pulverize it into powder, stir while pulverizing, and pulverize for 15-23 minutes;

[0023] Step 3. Put the aluminum alloy solution, anti-aging agent, rubber powder, high manganese steel powder, silicone oil, and oxidant into the molding equipment in sequence, and then start molding. The molding time is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com