Novel damper with adjustable stiffness and damping for high speed train

A technology for high-speed trains and dampers, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the inconvenience of manual manual adjustment of mechanical structures, the inability of the dampers to be automatically and continuously adjusted, and the inability to change the dampers at the same time. Stiffness and other issues, to achieve the effect of convenient processing and maintenance, simple structure, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings to further understand the purpose, scheme and benefits of the present invention, but it is not intended to limit the protection scope of the claims of the present invention.

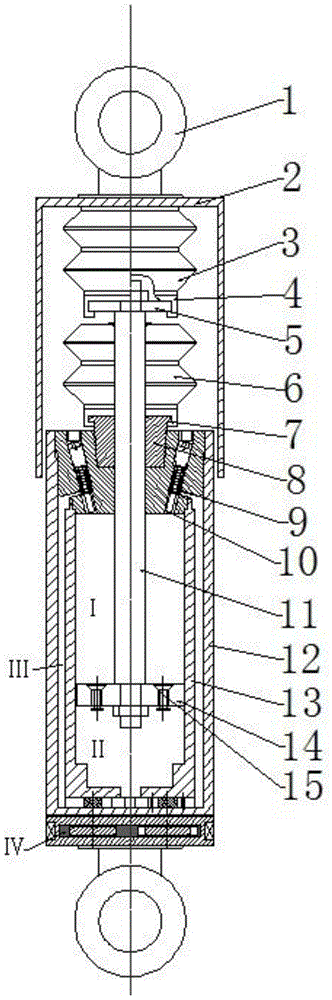

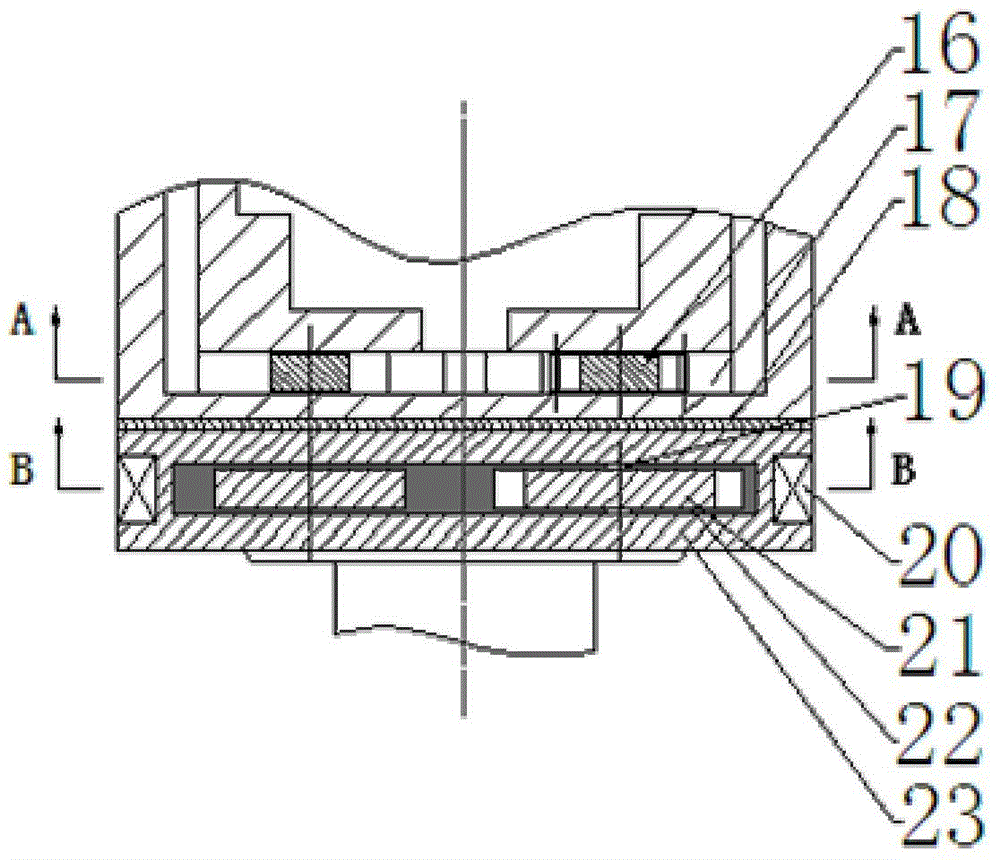

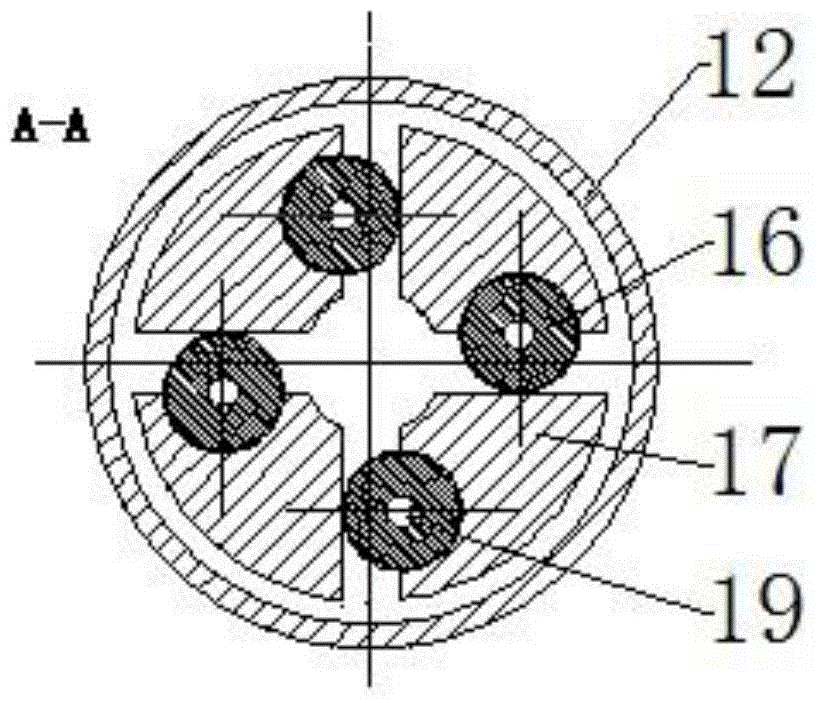

[0026] Such as figure 1 As shown, a new type of damper for adjustable stiffness damping on high-speed trains, including a dust cover 2, a magneto-rheological damper and a magneto-rheological valve, the top of the dust cover 2 is fixedly installed and connected to 1 A first-level connection spring 3 is fixed inside the top end, and the open mouth at the lower end is outside the upper end of the magnetorheological damper; the bottom screw of the magnetorheological damper is equipped with a magnetorheological valve;

[0027] The magnetorheological damper includes an outer cylinder 12, the lower end of the dustproof cover 2 is open outside the outer cylinder 12 of the magnetorheological damper, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com