Control method for high-transmission-ratio spaced shifting of tandem type electric transmission vehicle

A technology with large transmission ratio and control method, which is applied in the direction of transmission control, multi-transmission ratio transmission, transmission components, etc., can solve the problems of easy ablation, large temperature rise of the friction plate of the operating part, and increased sliding and friction power. , to achieve the effect of not easy to ablate, reduce speed difference, and avoid temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

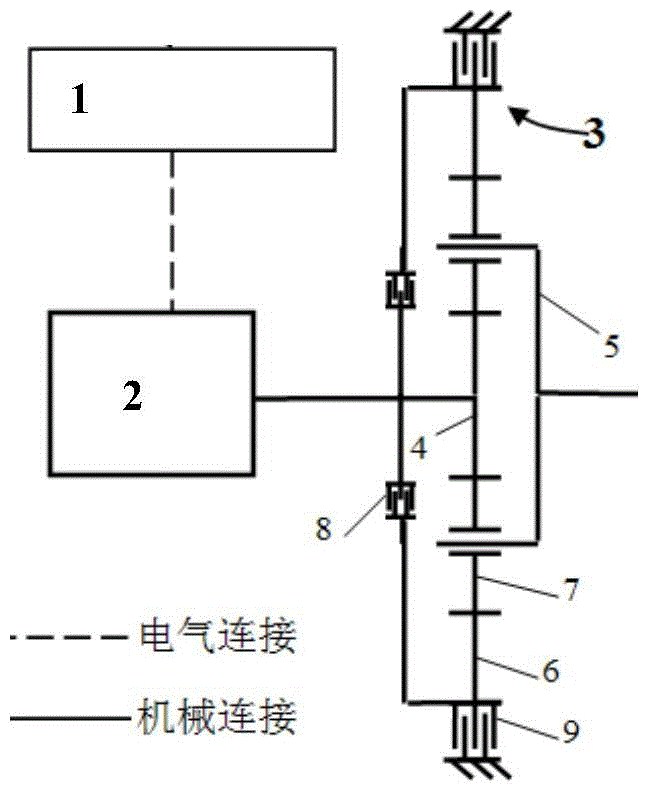

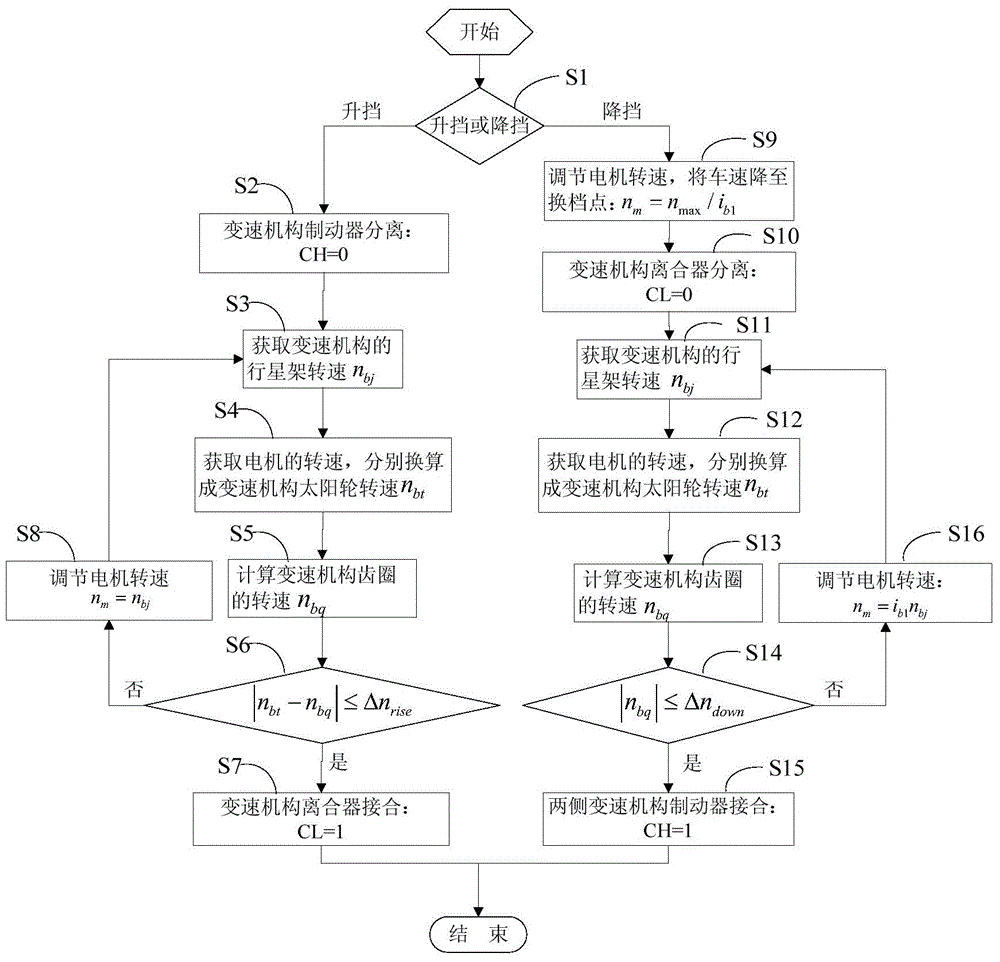

[0045] Such as Figure 1-2 As shown, the invention of this example is used for a large transmission ratio interval shift control method of a series electric transmission vehicle, and the method is realized through the transmission system of a series electric transmission vehicle; the method includes an upshift control process and a downshift control process .

[0046] Such as figure 2 As shown, in step S1, the transmission system integrated controller (TCU) included in the transmission system of the series electric transmission vehicle judges whether it is an upshift control process or a downshift control process according to the driver's manipulation signal.

[0047] If there is an upshift, then enter step S2, the steps of the upshift control process include: the transmission system integrated controller (TCU) sends a brake release command to the control valve of the brake of the speed change mechanism 3: CH=0. Then enter step S3, the transmission system integrated control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com