Pipeline elbow trend parameter measurement method for detectors in pipeline

A technology for pipeline elbows and internal detectors, which is applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., and can solve problems such as hidden dangers in pipeline safe operation and changes in curvature radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

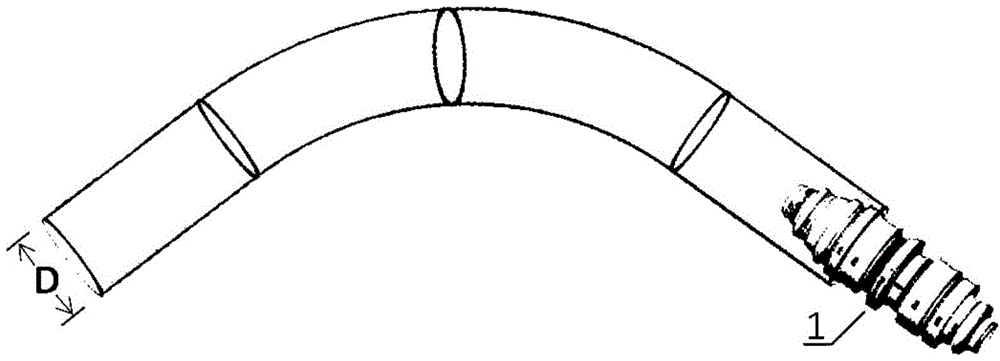

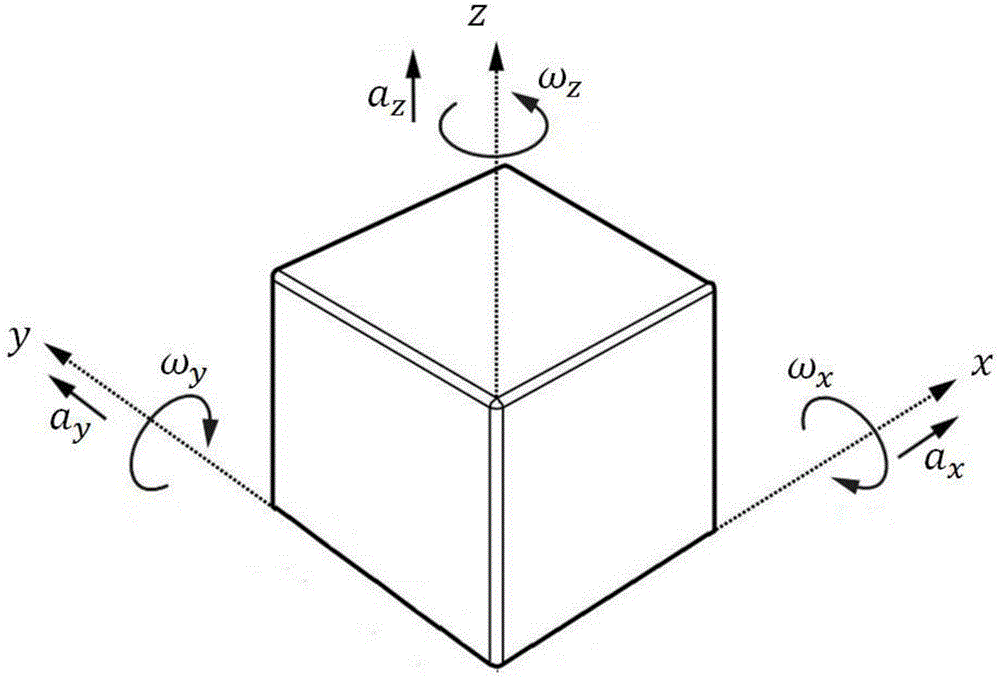

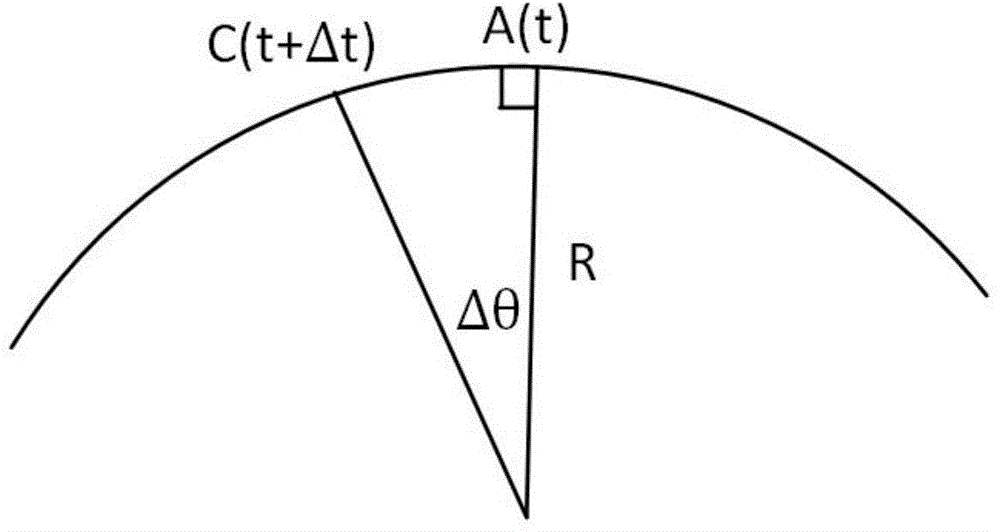

[0014] see Figure 1-2 , the embodiment of the present invention provides a method for measuring parameters of a pipeline elbow direction for an in-pipeline detector, which includes using a gyroscope sensor and an acceleration sensor in the intelligent detection of buried long-distance pipelines to obtain information about the pipeline elbow; The movement in the pipe elbow, the gyro sensor and the acceleration sensor are set on the detector 1, connected with the detector 1, and the motion signal is transmitted to the gyro sensor and the acceleration sensor; the acceleration sensor determines the detector by measuring the acceleration of gravity 1 Space attitude in the pipeline; the output of the gyroscope sensor is the angular velocity change rate ω when the inner detector rotates along different coordinate axes during the travel process x , ω y , ω z ;The adopted gyroscope sensor and acceleration sensor are respectively installed on three mutually perpendicular planes compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com