Device and method for measuring warping degree of substrate, touch screen and manufacturing method of touch screen

A measuring device and warpage technology, which is applied in the direction of measuring devices, optical devices, and data processing input/output processes, can solve problems such as easy generation of bubbles, easy fall-off, and impact on the yield of external touch screens, and achieve improvement. Yield rate and productivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific implementations of the measuring device and measuring method for the degree of warpage of the substrate, the touch screen and the manufacturing method provided in the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

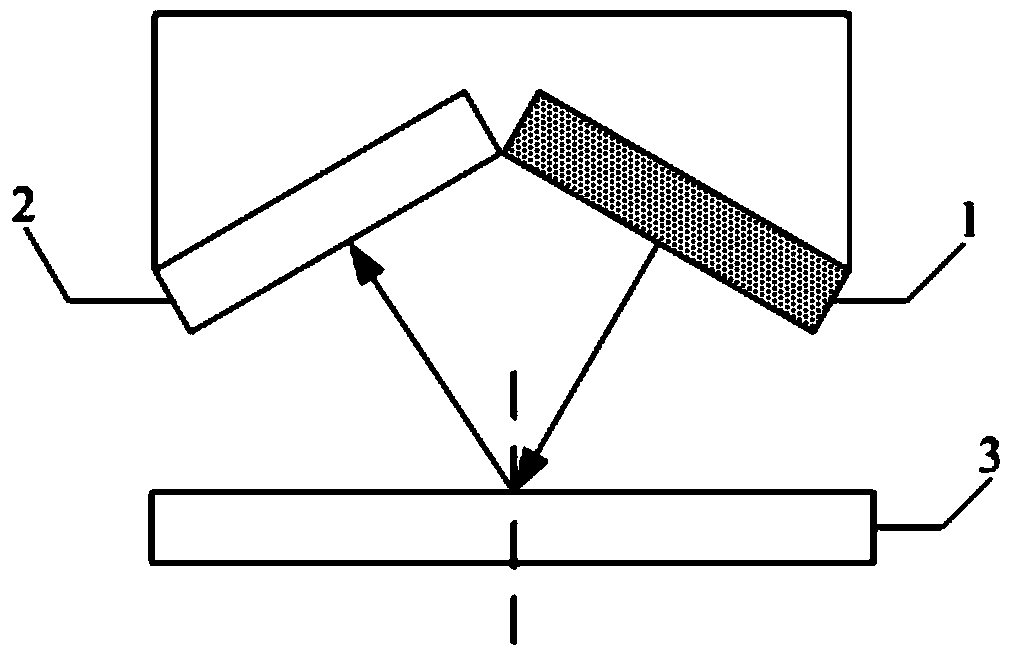

[0049] An embodiment of the present invention provides a substrate warpage measuring device, such as figure 1 shown, including: at least one laser 1 ( figure 1 Only one laser is shown) and a charge coupled device 2 (Charge Coupled Device, CCD) corresponding to and fixedly connected to the laser 1;

[0050] The laser 1 is used to emit laser light to the surface to be measured of the substrate 3 at a preset incident angle;

[0051] The charge-coupled device 2 is used for receiving the laser light emitted by the corresponding laser 1 and reflected on the surface to be measured of the substrate 3 .

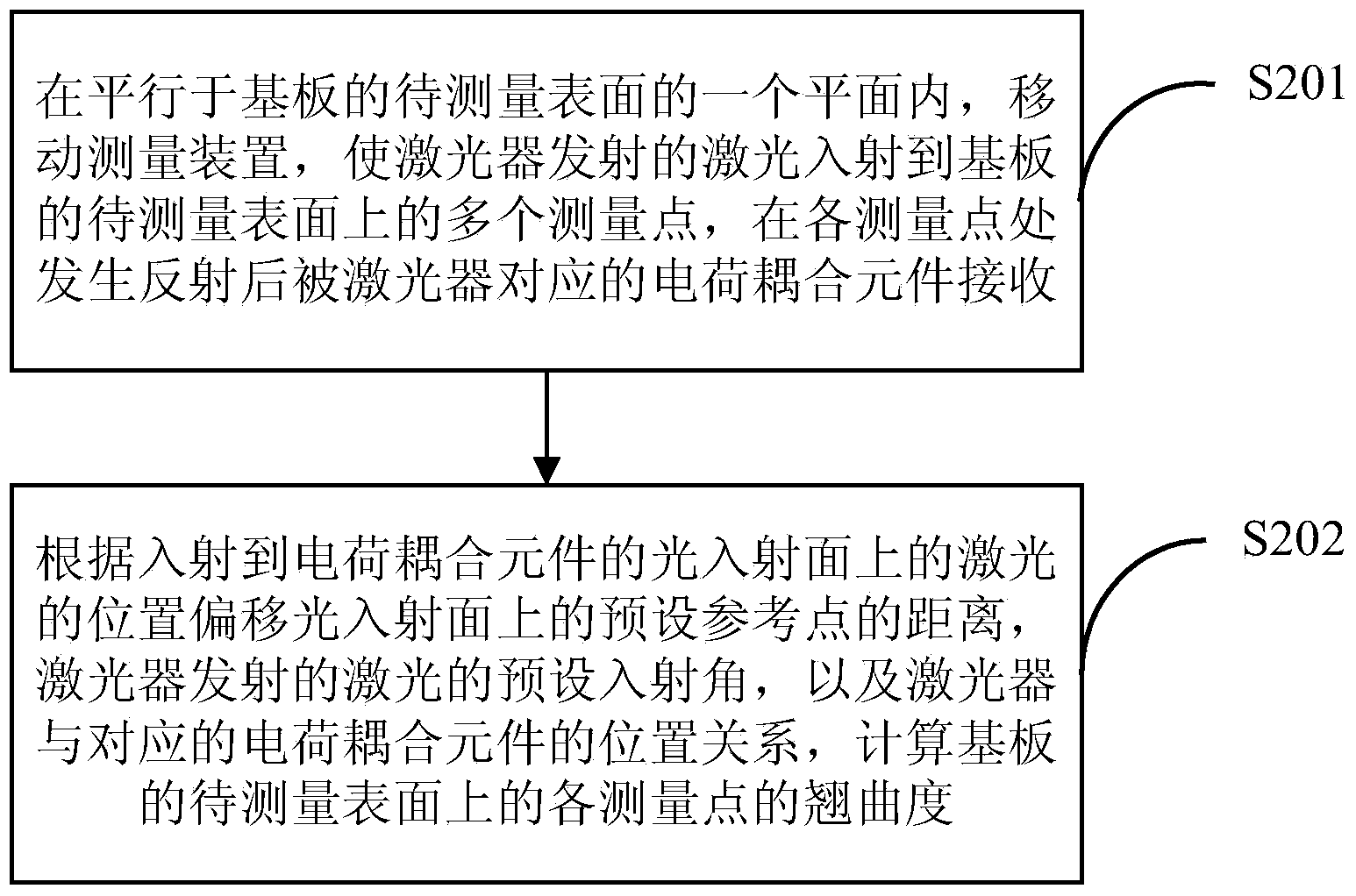

[0052] Based on the same inventive concept, an embodiment of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com