Flat Top Photonic Bandgap Fiber

A photonic bandgap and optical fiber technology, applied in the field of flat-top photonic bandgap fiber, can solve problems such as poor system stability and achieve the effect of increasing the mode field area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

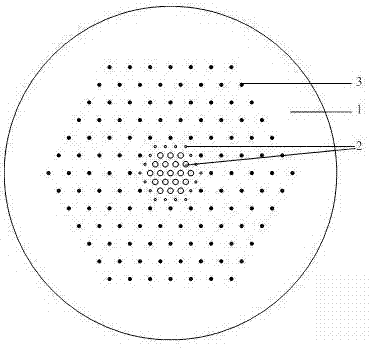

[0014] A flat-top photonic bandgap fiber is composed of two low-refractive-index dielectric pillars 2 with different diameters, wherein the inner low-refractive-index dielectric pillar 2 has a larger diameter, while the outermost low-refractive-index dielectric pillar 2 has a smaller diameter , so as to obtain a better refractive index distribution. By adjusting the diameter of the dielectric column, the equivalent refractive index in different regions of the fiber core can be adjusted, so that the distribution of the refractive index in the fiber core region can be precisely controlled. During fabrication, the low-refractive-index medium columns have the same refractive index, which also reduces the complexity of the fabrication process.

[0015] figure 1 A cross-sectional schematic view of an embodiment of the present invention is provided, the optical fiber comprises a core and a cladding, the core is made of a low-refractive index dielectric column 2 and a matrix material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com