A suspended edge coupler for mid-infrared band

An infrared band and coupler technology, applied in the field of couplers, can solve the problems of large waveguide-fiber coupling loss in the mid-infrared band, and achieve the effects of convenient testing, increased coupling area, and increased process tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

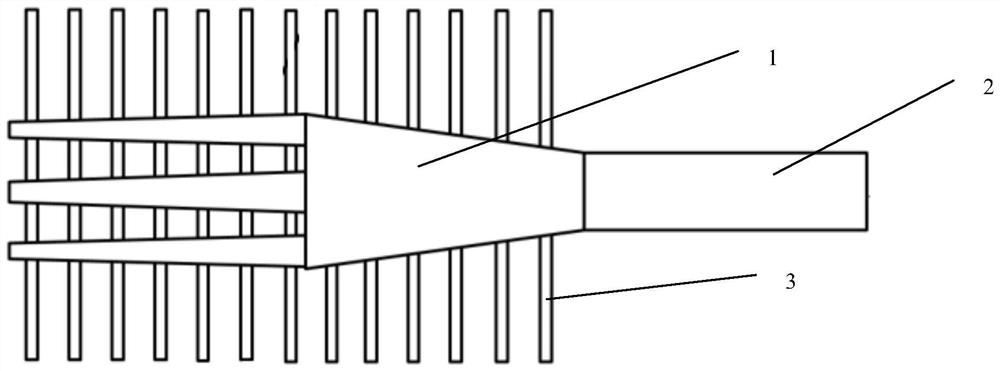

[0016] Depend on figure 1 As shown, this embodiment provides a suspended edge coupler applied in the mid-infrared band, including a three-port inverted cone coupler 1, a suspended ridge waveguide 2 and a cantilever arm support structure 3; the three-port inverted cone The shaped coupler 1 is directly connected to the suspended ridge waveguide 2; the cantilever arm support structure 3 is used to support the three-port inverted tapered coupler 1. The ports in the three-port inverted tapered coupler 1 are used to receive light input in the mid-infrared band. The cantilever arm support structure 3 is composed of a plurality of parallel strip waveguides.

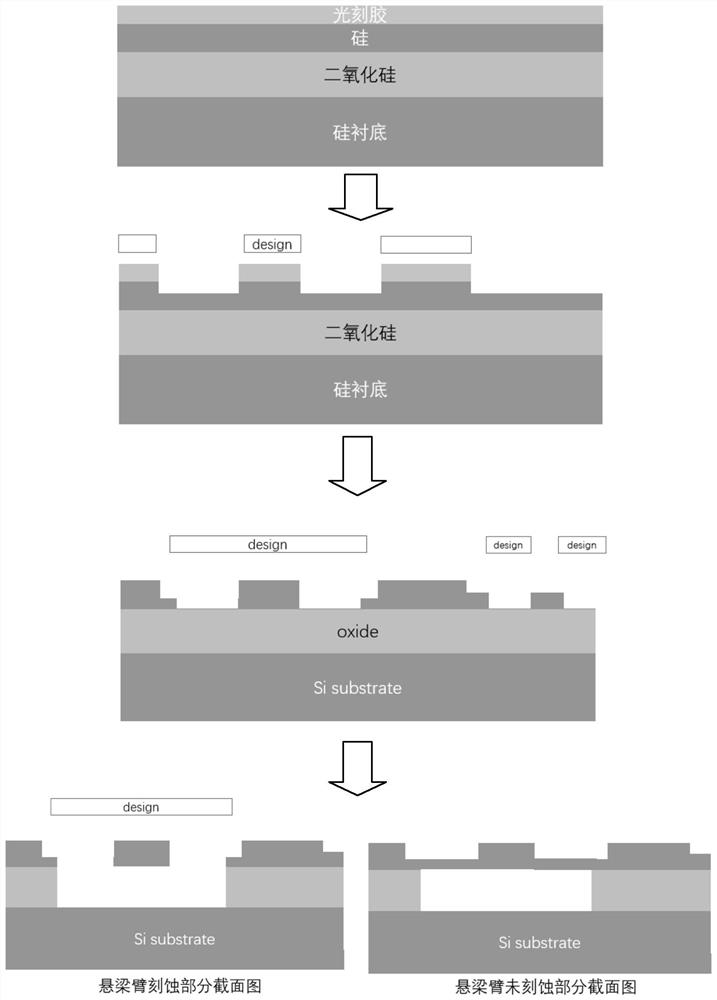

[0017] Depend on figure 2 As shown, this embodiment also provides a method for preparing a suspended edge coupler applied in the mid-infrared band, including the following steps:

[0018] (1) This structure is suitable for SOI materials of silicon photonics devices, in which the thickness of the silicon dioxide layer is gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com