An active optical fiber for homogenizing the light intensity distribution of the fundamental mode and its preparation method

A technology of light intensity distribution and fundamental mode, applied in multi-layer core/clad fibers, glass fibers, clad fibers, etc., can solve the problems of easy-to-trigger nonlinear effects and uneven distribution of fiber light intensity, and achieve the highest reduction. Power Density, Enlarged Mode Field Area, and Effects of Suppressing Higher-Order Mode Gains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] For the second solution provided by the present invention, a method for preparing an active optical fiber for homogenizing the light intensity distribution of the fundamental mode is provided, and the preparation method is used to prepare the method for homogenizing the fundamental mode in the aforementioned first solution An active optical fiber for light intensity distribution, comprising the steps of:

[0024] (1) The first soot body is deposited on the inner wall of the quartz glass tube by chemical vapor deposition, and the first soot body is sintered once to form the outer fiber core. Before this step is executed, MCVD (Modified Chemical VaporDeposition) equipment can be used to polish the inner wall of the high-purity quartz glass tube to remove impurities on the inner wall surface; during this step, MCVD equipment is used, and the reaction temperature is 1600~1800 Introduce SiCl under the condition of ℃ 4 、GeCl 4 and O 2 , depositing the first soot body on th...

Embodiment 1

[0030] In this embodiment, the preparation steps of the active optical fiber used to homogenize the light intensity distribution of the fundamental mode are as follows:

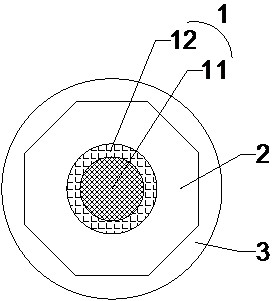

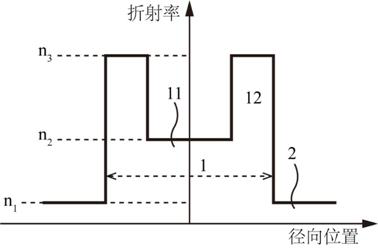

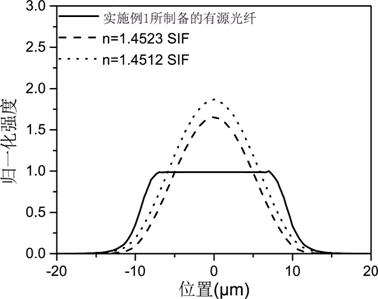

[0031] (1) Select a high-purity quartz glass tube with an outer diameter of 20 μm, use MCVD equipment to deposit the first soot on the inner wall of the quartz glass tube, and then perform a sintering, the temperature of the first sintering is 1600 ° C, and the time of the first sintering is 15 minutes , the outer fiber core was obtained by sintering the first soot body through high-temperature vitrification; the thickness of the outer fiber core was 3 μm, and its refractive index was 1.4523.

[0032] (2) MCVD equipment is used to deposit the second soot body on the inner wall of the outer fiber core, and a solution containing rare earth ions is prepared by mixing, and the quartz glass tube is immersed in the solution containing rare earth ions for doping, and the quartz glass is taken out after the doping is ...

Embodiment 2

[0037] The preparation steps of this embodiment are based on the preparation steps of the aforementioned Example 1, the difference is that the diameter of the inner fiber core is 16 μm, the thickness of the outer fiber core is 2 μm, and the refractive index of the outer fiber core 12 is 1.4529; at the same time, the comparison among them A SIF optical fiber has a refractive index of 1.4529, and other conditions are consistent with Embodiment 1.

[0038] In this example, the effective mode field area of the prepared active fiber fundamental mode is 396 μm 2 , schema, LP 11 The overlapping factors of the mode and the doped region are 0.596 and 0.431 respectively; for the SIF fiber with a refractive index n=1.4529, the effective mode field area of the fundamental mode is 216 μm 2 , schema, LP 11 The overlapping factors of the mode and the doped region are 0.873 and 0.716 respectively; for SIF fiber with a refractive index n=1.4512, the effective mode field area of the fun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com