Low-cost frame-free capacitive touch screen and manufacturing method thereof

A technology of capacitive touch screen and manufacturing method, applied in the direction of electric digital data processing, instrument, input/output process of data processing, etc., can solve the problems of complex manufacturing, difficult narrow frame, high input cost, etc., and achieve simple manufacturing process, production High efficiency and low loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

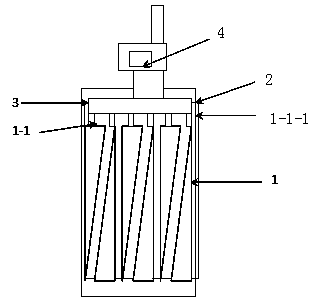

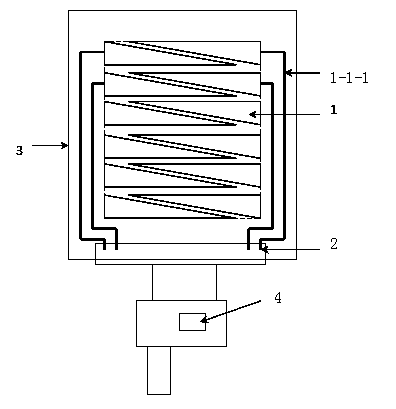

[0010] In order to understand the present invention more clearly, the present invention will be further described in conjunction with the following examples: Taking the 3.5-inch capacitive touch screen of a mobile phone as an example, the pattern of the indium tin oxide electrode 1 is a vertical triangle as the unit electrode 1, and each unit electrode 1 is heated and pressed in the longitudinal direction. There is a protruding head in the direction of the hot-pressing zone of the flexible circuit board 2 as the unit electrode wire 1-1, and the six triangular figures are placed facing each other so that the electrode wires are all in the direction of the hot-pressing zone. The flexible circuit board 2 is longitudinally hot-pressed, and the IC Components 4 are placed on the flexible circuit board 2 or the main board 3, and the steps are as follows:

[0011] 1. On the ITO glass, the pattern of indium tin oxide electrode 1 will be produced by using etching paste process. The thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com