A laser beam pulse timing synthesis device based on diffraction grating

A technology of laser beam and pulse timing, which is applied in the laser field, can solve the problems of increased complexity and synchronization control accuracy, and achieve the effect of increasing the number of synthesis channels, reducing the complexity and difficulty of synchronization control, and avoiding the decline of synthesis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

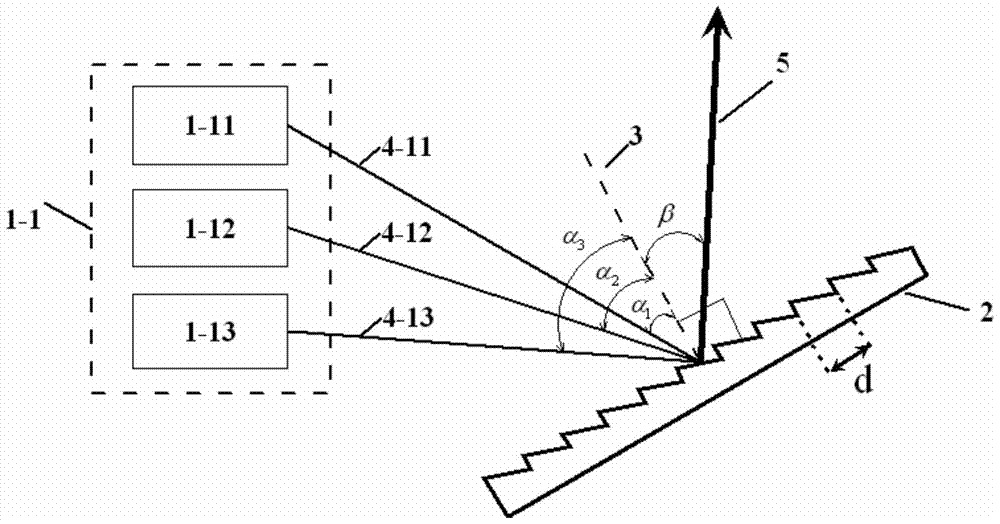

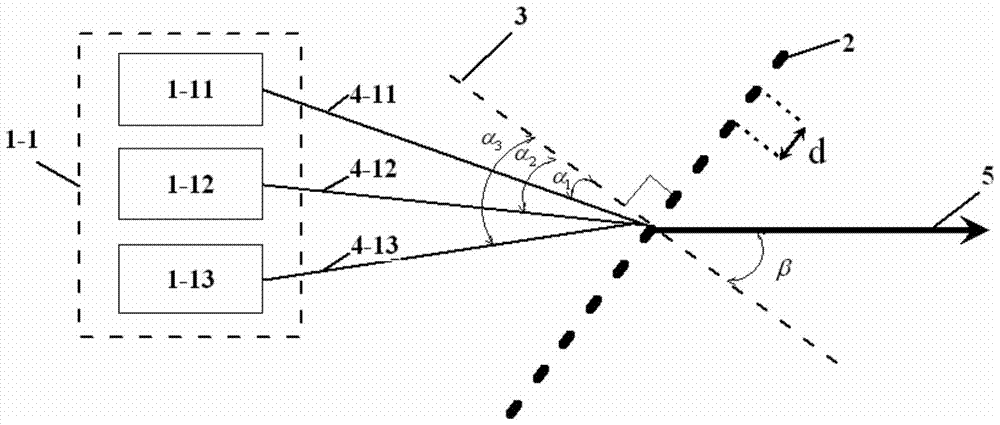

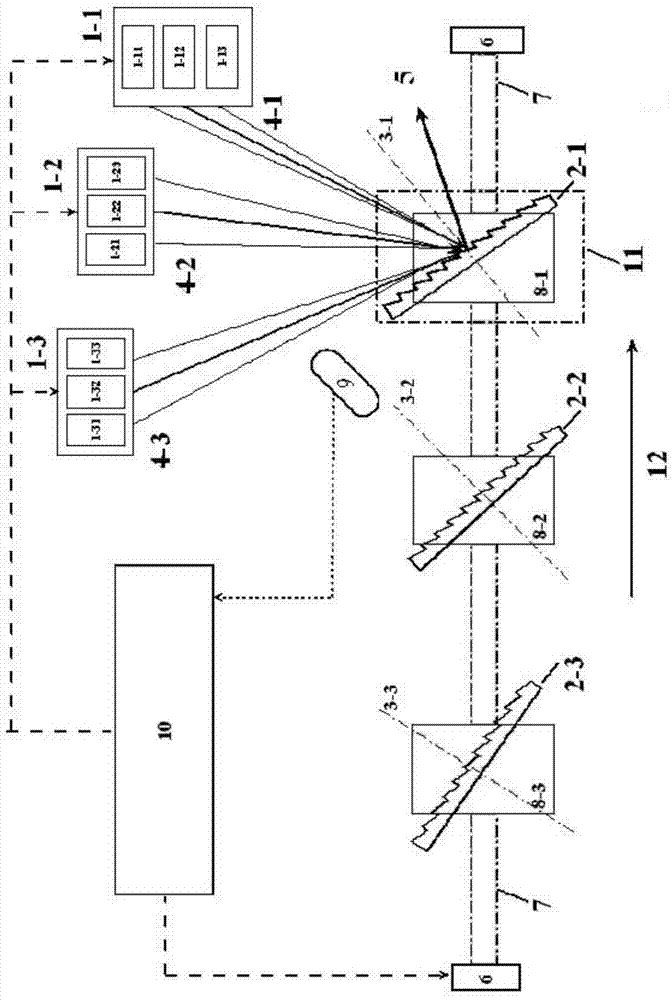

[0041] See image 3 , which is a schematic structural diagram of a laser beam pulse timing synthesis device based on a cyclically moving reflective grating.

[0042] In the first embodiment, each pulse laser group is matched with its own grating, the position of the pulse laser group is fixed, and all the gratings are installed on the transmission device; the transmission device is connected with the synchronous control device, so that all The synchronous control device obtains the position information of the grating in the transmission device; the transmission device includes a motor and a main transmission member; the motor drives the main transmission member to move; the grating is installed on the main transmission member, and Driven by the main transmission member, it performs periodic movement in the same direction, so that the grating sequentially reaches the corresponding working position of the pulse laser group.

[0043] In the first embodiment, the pulsed laser uni...

Embodiment 2

[0056] See Figure 4 , which is a schematic structural diagram of a laser beam pulse timing synthesis device based on a vertically reciprocating transmission grating.

[0057] In the second embodiment, each pulse laser group is matched with its own grating, all the pulse laser groups are located on the same plane and their positions are fixed, and the sub-lasers of each pulse laser group are respectively located on both sides of the main optical path; The grating and the pulse laser group are distributed at intervals in the direction of the main optical path, and all the gratings are located in front of the matched pulse laser group and installed on their corresponding grating driving devices; the grating driving device and the The synchronous control device is connected to drive the grating to move periodically under the control of the synchronous control device. It should be noted here that all the gratings located in front of the matched pulse laser group refer to being lo...

Embodiment 3

[0067] See Figure 5 , which is a structural schematic diagram of a laser beam pulse timing synthesis device based on a fan-shaped or circular-moving transmission grating.

[0068] Different from the first embodiment, the main transmission part in the third embodiment is the rotating shaft 14 . The pulsed laser groups are sequentially distributed on one side of the rotating shaft 14 along the axial direction of the rotating shaft, and all the pulsed laser groups are located on the same plane; On both sides; the grating is installed in the laser transmission direction of the matched pulse laser group; and the grating and the pulse laser group are distributed axially at intervals; the grating is along the circumferential direction of the rotating shaft are distributed sequentially so that when the rotating shaft rotates, the grating passes through the planes where all the pulsed laser groups are located, and intersects with the main optical path 5; and, the fixed position of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com