Base resin for soldering flux, soldering flux and solder paste

A basic resin and flux technology, applied in the direction of welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of easy loss of electronic components, loss of adhesion, reduced fluidity, etc., and achieve excellent stability over time , Viscosity stability is small, the effect of improving color tone and crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The production method of ingredient (A) is not particularly limited, and various known methods can be used. Specific examples include the following methods 1 to 3 described below.

[0042] 1. A method comprising: purifying raw rosin (for example, gum rosin, wood rosin, tall oil rosin); and subjecting the purified product to a hydrogenation reaction and / or disproportionation reaction, thereby producing a component (a-1) containing a predetermined amount Component (A) to (a-3). In this method, rosin containing certain amounts of components (a-1) and (a-2) is preferably used as a raw material rosin, and such rosin can be identified by referring to academic literature known at the time of filing this application.

[0043] 2. A method comprising: purifying raw rosin; carrying out hydrogenation reaction and / or disproportionation reaction to the purified product, thereby preparing rosin containing a predetermined amount of component (a-3); adding a predetermined amount of com...

Embodiment

[0078] Hereinafter, the present invention is described in detail by way of Examples and Comparative Examples. However, it goes without saying that the scope of the present invention is not limited to the examples. The symbols "part" and "%" are by weight.

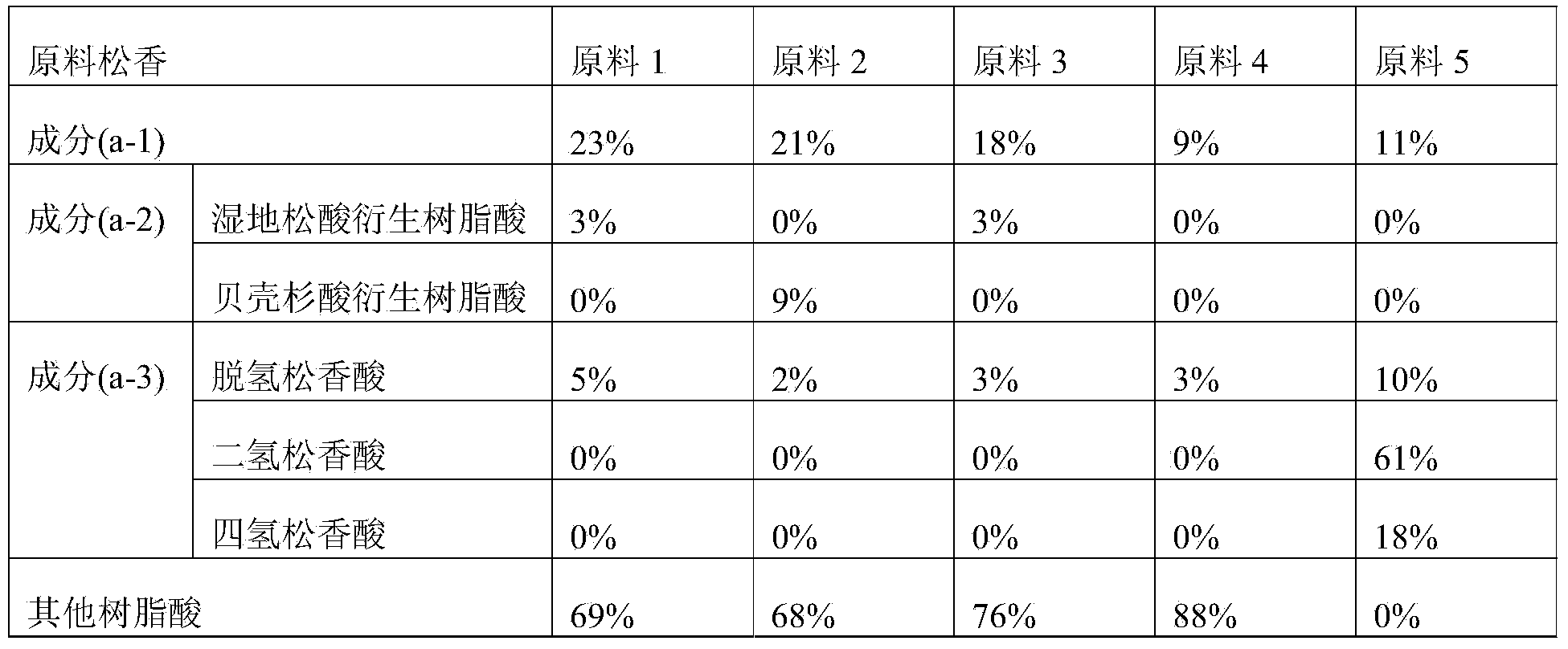

[0079] The compositional ratios of resin acids shown in Table 1 and Table 2 were measured by using a commercially available gas chromatography mass spectrometer (manufactured by Agilent Technologies, trade names "Agilent 6890" and "Agilent 5973N"). A commercially available column (manufactured by Shinwa Chemical Industries Ltd., trade name "Advance-DS") was used.

[0080] Preparation of Rosin (A)

preparation example 1

[0082] 185 g of Argentinian gum rosin (indicated as "raw material 1" in Table 1; Table 1 shows the raw materials of the following examples in the same manner) was placed in a vacuum distillation vessel, and was distilled under reduced pressure at 0.4 kPa in a nitrogen atmosphere , thus obtaining purified rosin. Subsequently, 150 g of purified rosin and 0.7 g of 5% palladium carbon (water content: 50%) were placed in a 0.3 L rotary autoclave, and oxygen in the system was removed, followed by pressurization to 10 MPa with hydrogen. The temperature was raised to 220° C., and a hydrogenation reaction was performed at the same temperature for 3 hours, thereby obtaining rosin (A1). Table 1 shows the composition ratio of the resin acids contained in the raw material rosin (raw material 1) and Table 2 shows the composition ratio of the resin acids contained in the rosin (A1) and the physical properties of the rosin (A1) (Table 1 and Table 1). 2 also shows the composition ratio of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com