Transplanting-free hydroponic culture plate with variable space and use method of transplanting-free hydroponic culture plate

A technology of cultivation board and spacing, applied in the field of transplant-free hydroponic cultivation board, to achieve the effect of shortening plant growth cycle, reducing loss and reducing plant infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 The free-transplanting hydroponic cultivation plate 1 with variable spacing of the present invention

[0046] The free-transplanting hydroponic cultivation board with variable spacing is set according to the demand for planting rapeseed.

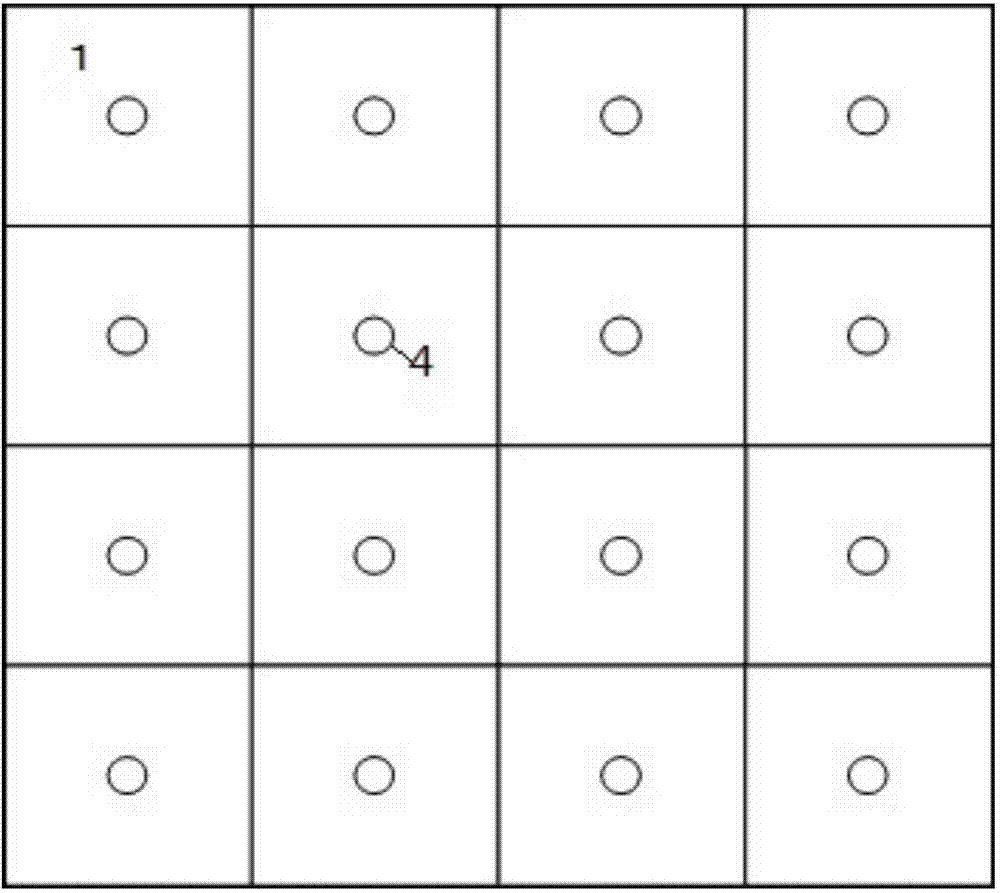

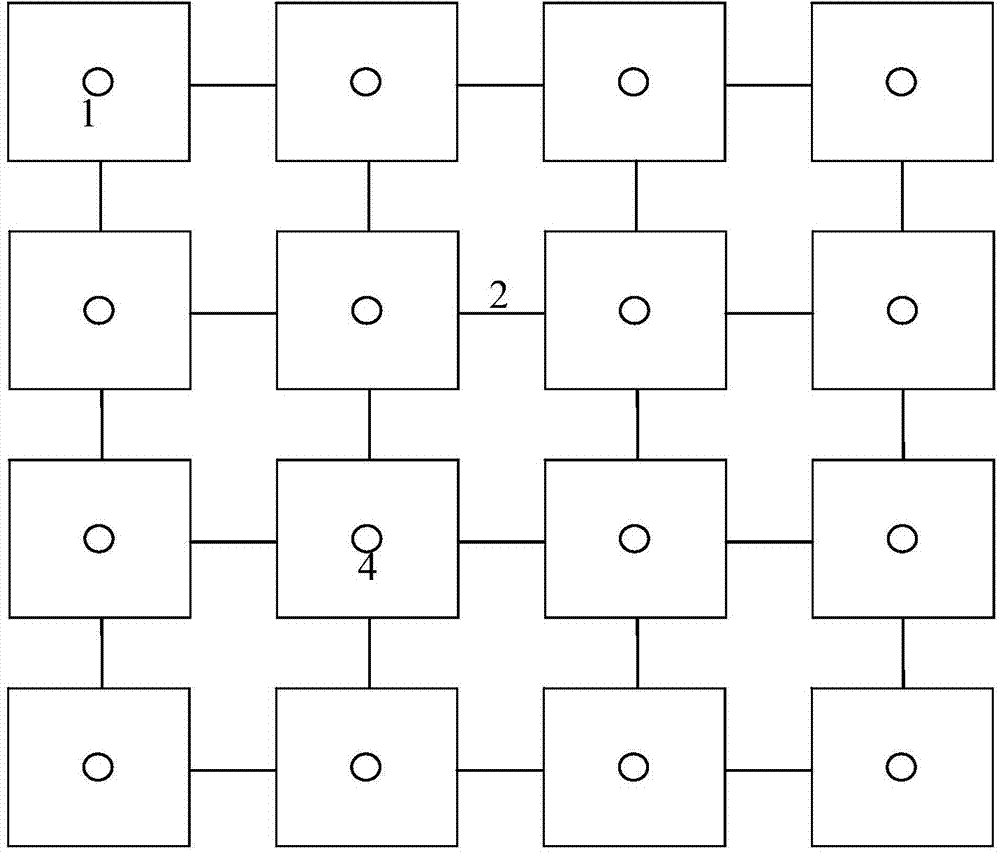

[0047] The structure of the free-transplanting hydroponic cultivation plate of the present embodiment is as follows: figure 1 , 2 As shown, it is composed of 4×4 square unit boards 1 and telescopic variable pitch connecting parts 2, and a planting hole 4 is provided in the center of each unit board.

[0048] The unit plate 1 used is a square polystyrene with a size of 3cm×3cm.

[0049] The unit board 1 is movably spliced with the variable pitch connecting part 2 . The structure of the variable pitch connecting part 2 used is telescopic. Referring to the antenna that can be stretched and shortened for TV or radio, it is composed of two sliding sleeves with a length of 2.7 cm and different thicknesses. In the thick ca...

Embodiment 2

[0051] Embodiment 2 The free-transplanting hydroponic cultivation plate 2 with variable spacing of the present invention

[0052] The free-transplanting hydroponic cultivation board with variable spacing is set according to the demand for planting loose-leaf lettuce.

[0053] The transplant-free hydroponic cultivation plate of this embodiment is composed of 2 x 2 square unit plates and telescopic variable-spacing connecting parts, and a planting hole is provided in the center of each unit plate.

[0054] The unit plate used is a square polystyrene with a size of 7cm×7cm, which is made hollow to increase the buoyancy.

[0055] All the space-variable connecting parts are connected to each other to form a stretchable frame, and the unit boards are spliced on the frame in a movable splicing manner. The structure of the variable-spacing connecting parts used is telescopic, which is composed of 5 sliding sleeves with a length of 6cm and different thicknesses. Partially exposed o...

Embodiment 3

[0057] Embodiment 3 The free-transplanting hydroponic cultivation plate 3 with variable spacing of the present invention

[0058] Set the free-transplanting hydroponic cultivation board with variable spacing according to the needs of planting butter lettuce.

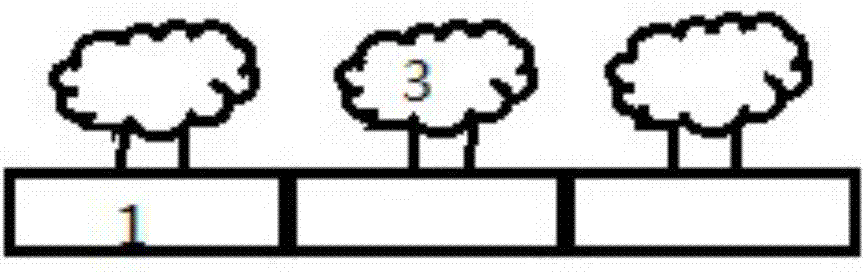

[0059] The transplant-free hydroponic cultivation board of this embodiment is composed of 3×3 square unit boards and foldable space-variable connecting parts, and a planting hole is arranged in the center of each unit board.

[0060] The unit plate used is a square polystyrene with a size of 5cm×5cm.

[0061] Each unit board is directly spliced with the variable-spacing connecting parts in the manner of movable splicing. The structure of the variable-spacing connecting parts used is foldable, consisting of three 5cm-long sticks riveted together with their heads and tails movably. When the spacing is short, the short sticks are folded with each other. The material used for the variable pitch connecting parts is polyte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com